Steering engagement and disengagement driving mechanism of combine-harvester

A technology of combine harvester and drive mechanism, applied in the direction of intermeshing clutch, harvester, mechanical drive clutch, etc., can solve the problems of serious internal friction plate wear, loss of inner crawler braking power, and shortened life, etc., and reaches the installation position. Accurate and reliable, improve cross-area operation performance, and improve the effect of driving speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

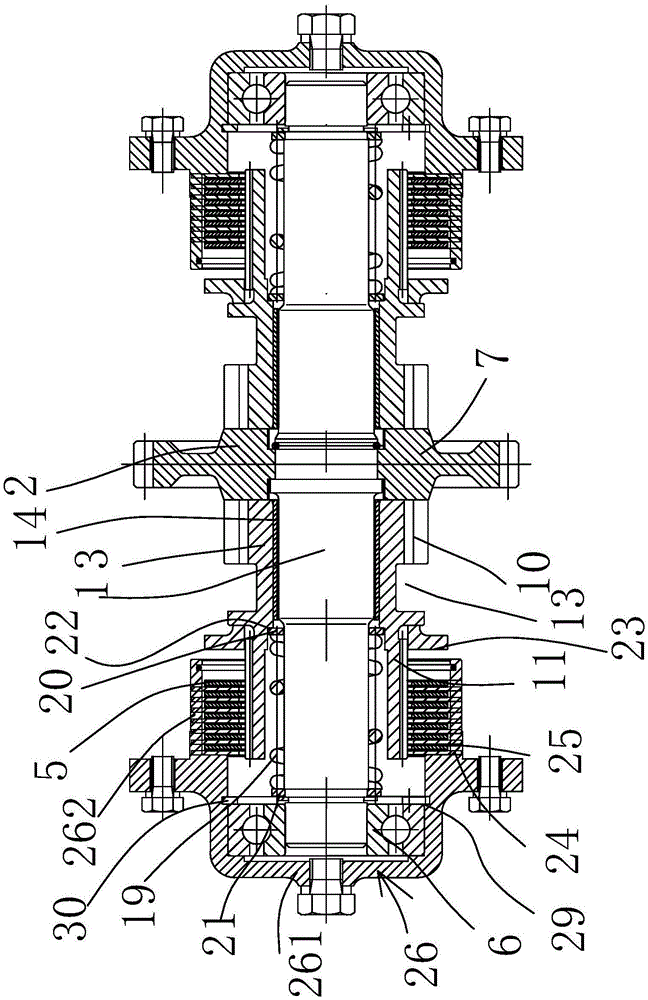

[0027] In the figure, the clutch steering shaft 1; the steering main gear assembly 2; the steering gear assembly 3; the steering fork assembly 4; the brake assembly 5; the shaft seal assembly 6; the steering main gear 7; the main spline gear block 8; the meshing space 9; Steering gear 10; extended matching kit 11; slave spline tooth block 12; shift fork port 13; sliding kit 14; steering clutch lever 15; steering shift fork 16; shift block 17; arc-shaped movable fork port 18; steering spring 19; Steering inner gasket 20; steering outer gasket 21; step blocking surface 22; thrust ring 23; partition plate 24; friction plate 25; clutch guard 26; fixed part 261; extension part 262; Lug 28 ; shaft seal accommodating groove 29 ; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com