Starch and expanded graphite phase-change composite material and method for preparing same

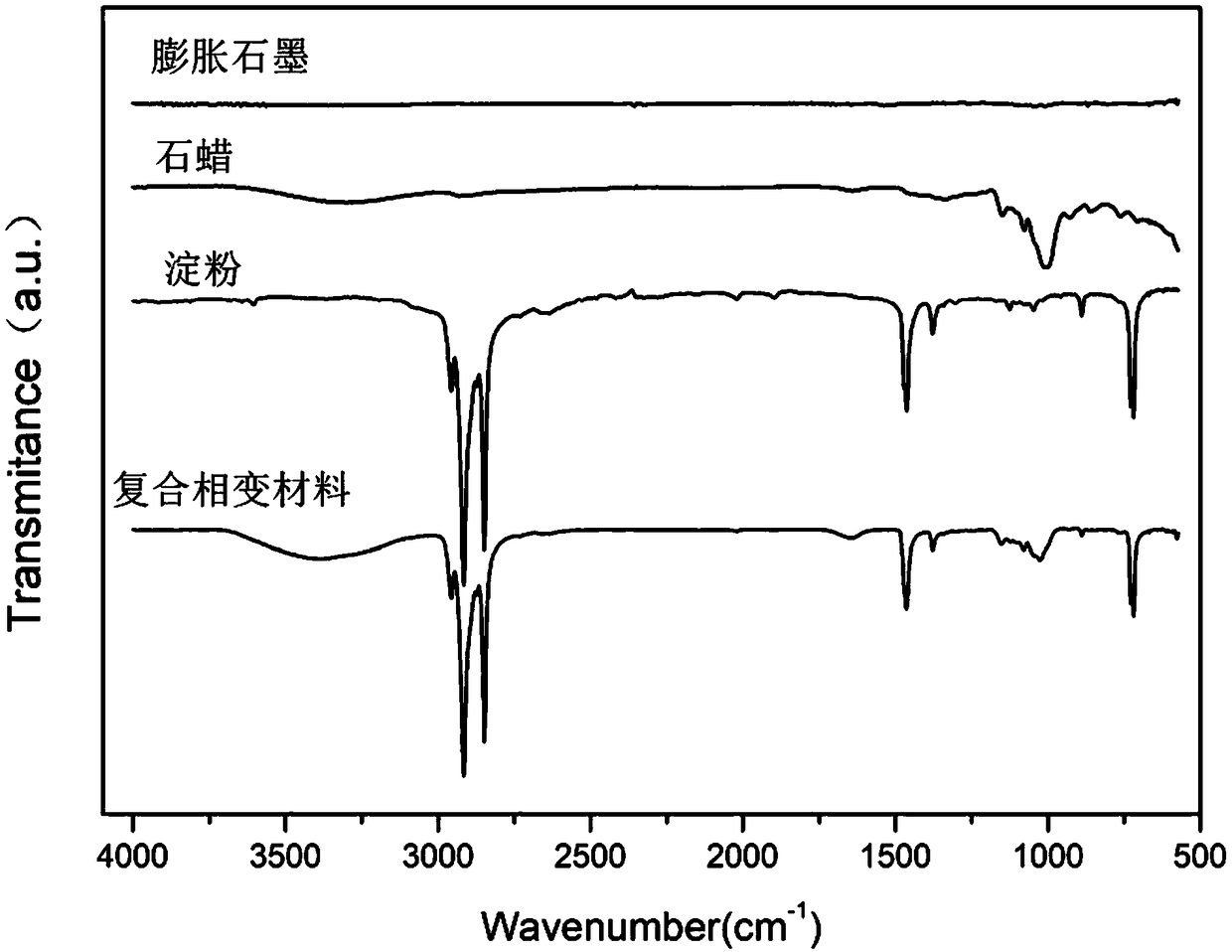

A phase change composite material and expanded graphite technology are applied in the field of starch expanded graphite phase change composite materials and their preparation, and can solve the problems of thin microcapsule shells, poor stability of microcapsule phase change composites, and microcapsule phase change. The composite material shell is broken and other problems, to achieve the effect of good encapsulation, excellent structural stability, and excellent thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Weigh 1 g of starch and disperse it in 100 ml of deionized water, and set the temperature of the constant temperature magnetic stirrer at 90°C. The starch suspension was heated under a magnetic stirrer, and after it boiled, continue to boil for 15 minutes.

[0032] (2) Transfer the boiling starch suspension to a high-speed shearing machine. Immediately add 0.5-1 g of expanded graphite to the boiling starch suspension, vigorously stir the starch-expanded graphite mixed suspension at 10,000 rpm under a high-speed shear, and form a fully dispersed suspension after stirring for 15 minutes.

[0033] (3) Heat 9 g of paraffin in a vacuum oven at 70° C. until it melts.

[0034] (4) Add molten paraffin to the suspension in (2), and vigorously stir at a speed of 10,000 rpm for 15 minutes under a high-speed shear.

[0035] (5) Filter the sample to remove its deionized water. Place in an oven at 35°C to dry, solidify the paraffin droplets and solidify the starch. After test...

Embodiment 2

[0037] (1) Weigh 1 g of starch and disperse it in 100 ml of deionized water, and set the temperature of the constant temperature magnetic stirrer at 90°C. The starch suspension was heated under a magnetic stirrer, and after it boiled, continue to boil for 15 minutes.

[0038] (2) Transfer the boiling starch suspension to a high-speed shearing machine. Then, 0.5 g of expanded graphite was immediately added to the boiling starch suspension, and the starch-expanded graphite mixed suspension was vigorously stirred at a speed of 10,000 rpm under a high-speed shear, and a fully dispersed suspension was formed after stirring for 15 minutes.

[0039] (3) Heat 4.45g of paraffin in a vacuum oven at 70°C until it melts.

[0040] (4) Add molten paraffin to the suspension in (2), and vigorously stir at a speed of 10,000 rpm for 15 minutes under a high-speed shear.

[0041](5) Filter the sample to remove its deionized water. Place in an oven at 35°C to dry, solidify the paraffin droplets...

Embodiment 3

[0044] (1) Weigh 1 g of starch and disperse it in 100 ml of deionized water, and set the temperature of the constant temperature magnetic stirrer at 90°C. The starch suspension was heated under a magnetic stirrer, and after it boiled, continue to boil for 15 minutes.

[0045] (2) Transfer the boiling starch suspension to a high-speed shearing machine. Then, 0.5 g of expanded graphite was immediately added to the boiling starch suspension, and the starch-expanded graphite mixed suspension was vigorously stirred at a speed of 10,000 rpm under a high-speed shear, and a fully dispersed suspension was formed after stirring for 15 minutes.

[0046] (3) 2.97g of paraffin was heated in a vacuum oven at 70°C until it melted. SEM images of starch, expanded graphite, paraffin, and phase change composites are shown in figure 2 middle. Figure A is the dispersed starch-expanded graphite phase-change composite material. It can be seen that the particles are spherical and the size is abou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com