Lithium-rich manganese base, spinel and graphene flexible composite positive electrode with sandwich core-shell structure and preparation method thereof

A core-shell structure, lithium-rich manganese-based technology, applied to structural parts, battery electrodes, electrical components, etc., can solve the problems of low energy density of lithium-rich manganese-based positive electrodes, low lithium ion diffusion rate, large irreversible capacity, etc., to achieve Excellent large-rate performance, improved lithium ion diffusion rate, and obvious and reliable performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

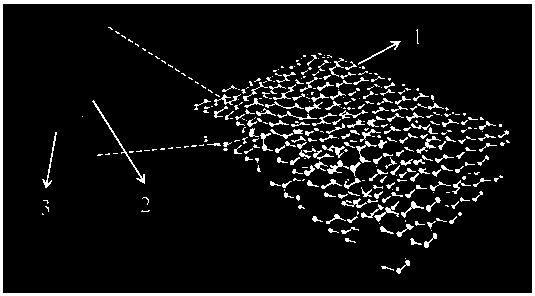

[0029] Specific embodiment one: a lithium-rich manganese-based, spinel and graphene flexible composite positive electrode with a sandwich core-shell structure, the chemical formula of the lithium-rich manganese-based positive electrode material is aLi 2 MnO 3 ·(1-a)LiMO 2 , the chemical formula of the spinel material is LiMn 2-x m x o 4 , where: 0.1≤a1-x-y Ni x co y , 0≤x≤0.5, 0≤y≤0.5.

[0030] The effect of this embodiment: improve the energy density, flexibility and plasticity of lithium-rich manganese-based positive electrodes; improve the cycle life of lithium-rich manganese-based materials; improve the diffusion rate of electrons and lithium ions in lithium-rich manganese-based materials; The improvement is obvious and reliable, and it has a large specific capacity and excellent rate and cycle performance.

specific Embodiment approach 2

[0031] Embodiment 2: A method for preparing a lithium-rich manganese-based, spinel, and graphene flexible composite positive electrode with a sandwich core-shell structure described in Embodiment 1. The method includes the following process steps:

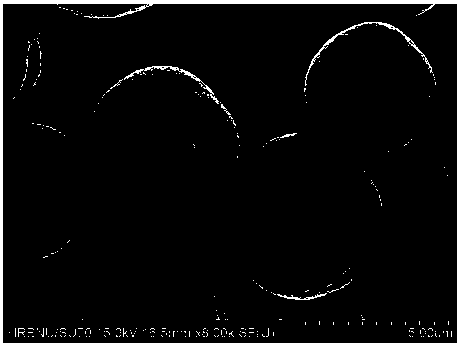

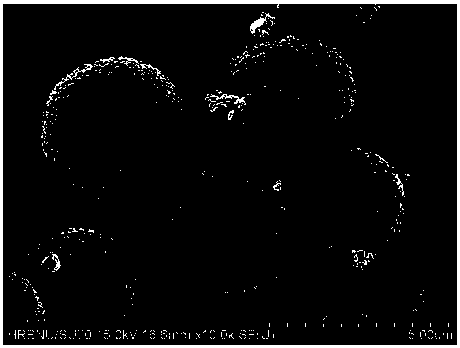

[0032] Step 1: Prepare manganese-nickel-cobalt carbonate spherical precursor by co-precipitation method;

[0033] Step 2: Uniformly mixing and calcining the manganese-nickel-cobalt carbonate spherical precursor obtained in step 1 and the lithium salt compound to obtain a spherical lithium-rich manganese-based positive electrode material;

[0034] Step 3: Mix the spherical lithium-rich manganese-based positive electrode material obtained in step 2 with the graphene oxide dispersion, and prepare the mixed spherical lithium-rich manganese-based positive electrode material and the graphene oxide dispersion by vacuum filtration to have a sandwich structure Lithium-rich manganese-based and graphene oxide composite films, and finally the ...

specific Embodiment approach 3

[0036] Specific embodiment three: the preparation method of the lithium-rich manganese-based, spinel and graphene flexible composite positive electrode of the sandwich core-shell structure described in the specific embodiment two, the specific steps of the step one are as follows:

[0037] Step (1): Weigh the manganese salt compound, nickel salt compound and cobalt salt compound respectively, and dissolve them all in deionized water and mix them evenly to prepare a mixed metal salt solution M of 0.1~1 mol / L;

[0038] Step (2): Weigh the carbonate precipitant and complexing agent respectively, dissolve them in deionized water and mix them evenly to prepare a mixed solution of carbonate precipitant and complexing agent at 0.1-1 mol / L;

[0039] Step (3): Add the prepared mixed solution of carbonate precipitation agent and complexing agent into the mixed metal salt solution M in step (1) under strong stirring to control the precipitation of mixed metal salt and carbonate The molar r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com