Distributed point-by-point follow-up spray type temperature-control fire-fighting system with memory alloy spring

A memory alloy spring, fire protection system technology, applied in engine components, valve operation/release devices, valve details, etc., can solve the problems of narrow control field, inability to carry out timely and effective control, debugging, and inconvenient control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

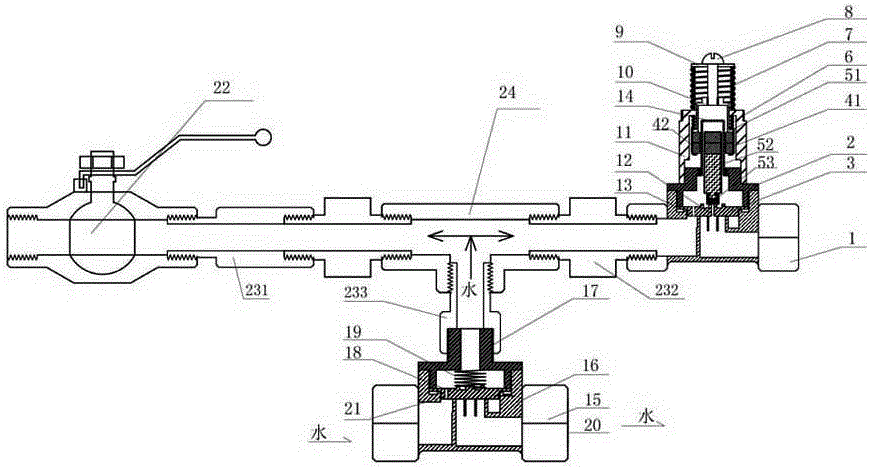

[0021] Under normal conditions, the memory alloy spring (7) is under pressure, and the magnetic ring assembly (4) is pushed down to drive the magnetic core assembly (5) to move down by means of magnetic force, to block the pressure relief hole (12), and to close the auxiliary valve. At the same time, the magnetic ring assembly (4) drives the connecting cylinder (10) to move down, and produces relative motion with the stationary handle (11), so that the screw (8) presses down on the spring seat (9) Make the memory alloy spring (7) in a compressed state.

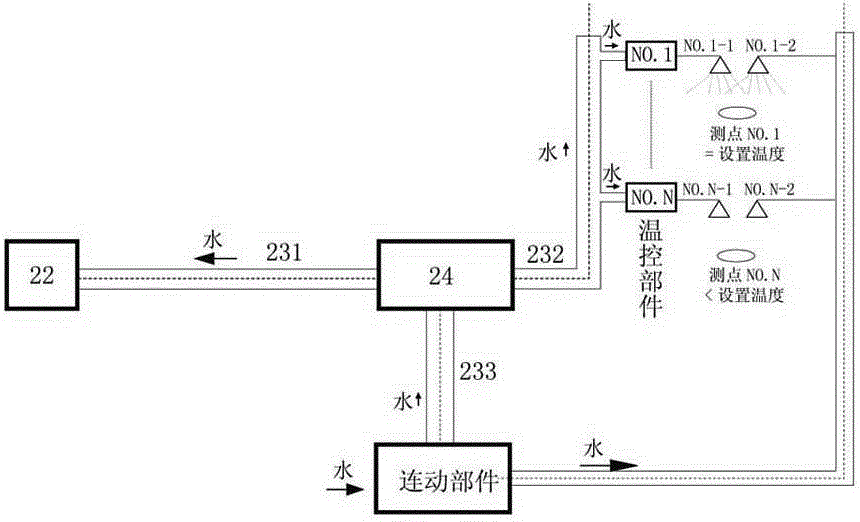

[0022] At this time, the inlet water pressure enters the upper part of the main diaphragm piston (18) through the main valve upper pressure hole (21) on the main diaphragm piston (18). , the auxiliary valve body (1) including the temperature control parts and the manual shut-off valve (22) are closed, and the pressure entering through the upper pressure hole (21) of the main valve cannot be discharged, causing the upper part o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com