Semiconductor device and preparation method thereof

A technology of semiconductors and devices, which is applied in the field of semiconductor chip manufacturing technology, and can solve problems such as metals are easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

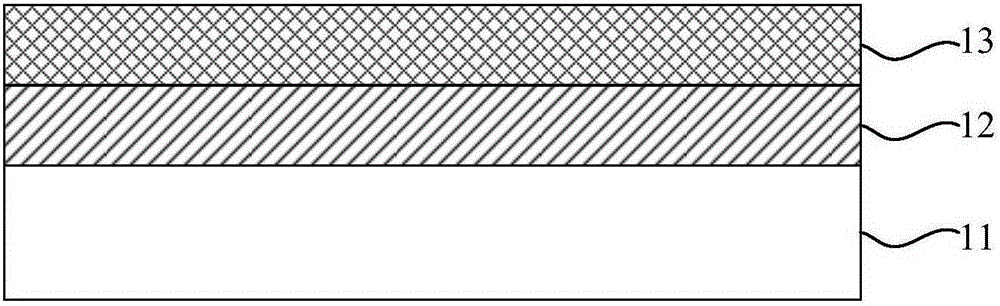

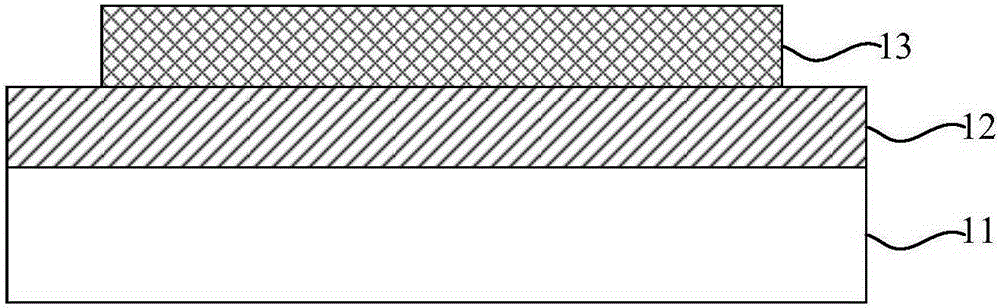

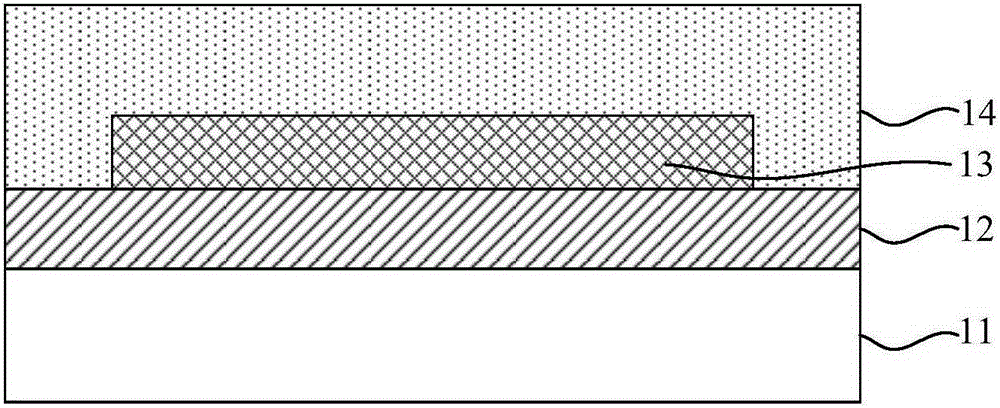

[0083] A method for preparing a GaN semiconductor device provided in Embodiment 1 of the present invention specifically includes:

[0084] see Figure 15 , the buffer layer 22 and the barrier layer 23 are sequentially prepared on the upper surface of the polysilicon semiconductor substrate 21 by processes such as deposition.

[0085] Wherein, the above-mentioned buffer layer 22 covers the upper surface of the semiconductor substrate 21, and the barrier layer 23 covers the upper surface of the above-mentioned buffer layer 22, so that the above-mentioned semiconductor substrate 21, the buffer layer 22 and the barrier layer 23 can be used as the subsequent preparation of the semiconductor substrate. the substrate of the device.

[0086] The buffer layer 22 can be made of gallium nitride (GaN) and the barrier layer 23 can be made of aluminum gallium nitride (AlGaN).

[0087] The buffer layer 22 has a thickness of about 675 μm, and the barrier layer 23 has a thickness of about 20...

Embodiment 2

[0112] A method for preparing a semiconductor device provided in Embodiment 2 of the present invention specifically includes:

[0113] see Figure 29 , the buffer layer 32 and the barrier layer 33 are sequentially prepared on the upper surface of the polysilicon semiconductor substrate 31 by processes such as deposition.

[0114] Wherein, the above-mentioned buffer layer 32 covers the upper surface of the semiconductor substrate 31, and the barrier layer 33 covers the upper surface of the above-mentioned buffer layer 32, so that the above-mentioned semiconductor substrate 31, buffer layer 32 and barrier layer 33 can be used as the subsequent preparation of GaN Substrates for semiconductor devices.

[0115] The buffer layer 32 may be made of gallium nitride (GaN), and the barrier layer 33 may be made of aluminum gallium nitride (AlGaN).

[0116] The buffer layer 32 has a thickness of about 675 μm, and the barrier layer 33 has a thickness of about 200A to 300A.

[0117] see ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com