Processing method of conductive plasticine used for fixing SEM (Scanning Electron Microscope) sample

A technology of electron microscopy and conductive rubber, which is applied in the direction of conductive materials dispersed in non-conductive inorganic materials, cable/conductor manufacturing, circuits, etc., and can solve the problems of polluting microscope lenses and conductive powder falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

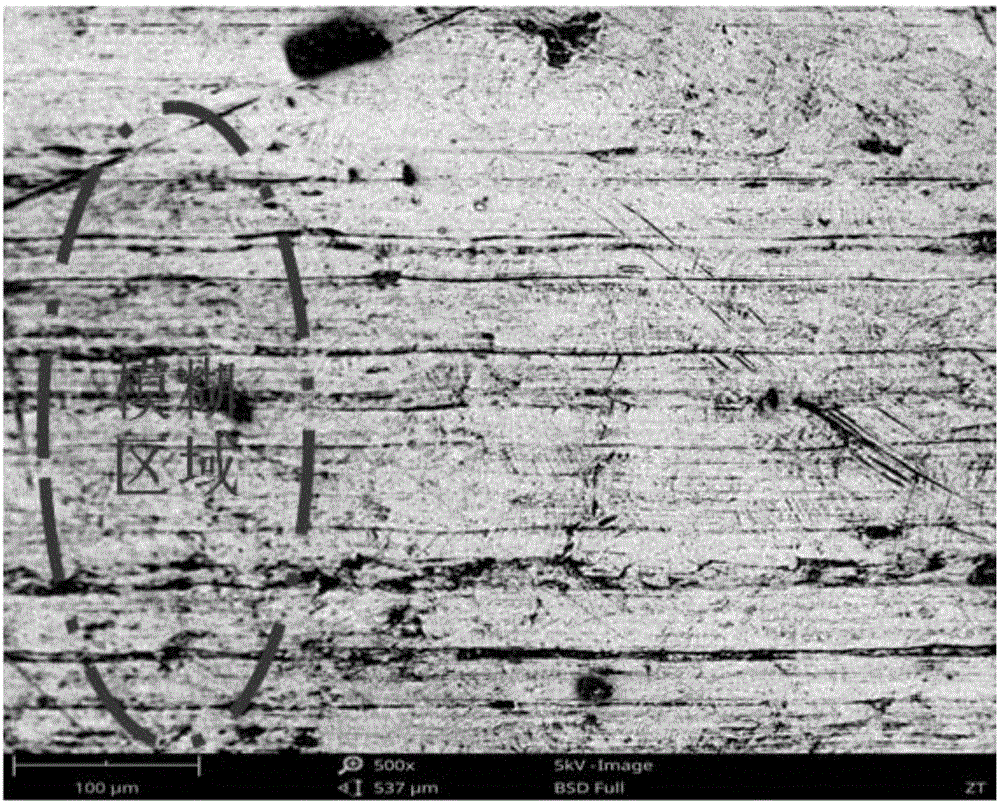

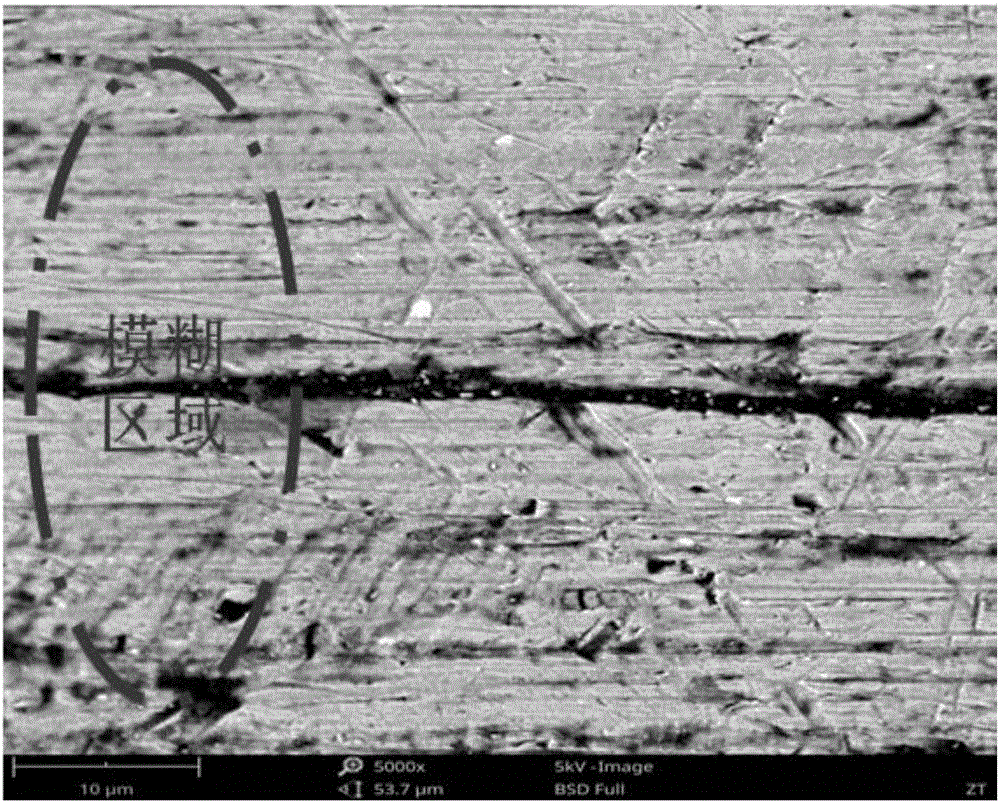

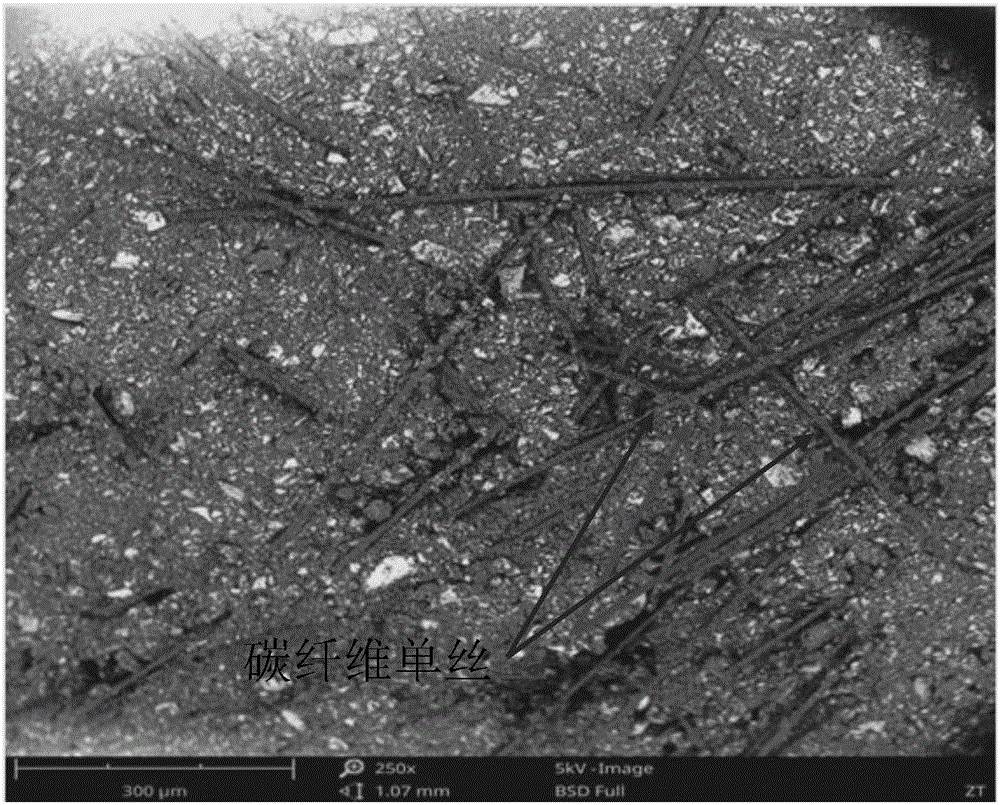

[0013] Specific embodiments of the present invention such as Figure 1-4 Shown is the processing method of conductive plasticine for fixing scanning electron microscope samples, which is characterized in that it includes the following steps: ① using metallographic plasticine, heating it to 25 ° C, ② placing the plasticine on a smooth glass plane , use a round stick to flatten it to a sheet with a thickness of 1mm, ③sprinkle 1cm long carbon fiber monofilament without sizing and glue on the surface of the sheet, the carbon content of carbon fiber is ≥95%, and the resistivity is ≤1.5×10 ﹣3 Ωcm, carbon fiber monofilaments overlap each other to form a staggered two-dimensional structure, and then use a round stick to gently press the carbon fiber into the plasticine. ④ Gently brush the surface of the plasticine with a soft brush to remove unfixed carbon fiber monofilaments , ⑤For the position where carbon fiber monofilaments are sparsely distributed on the surface, repeat ③~④ to en...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com