Anti-pumping-out device for wastewater pool and application method of device

A technology for evacuation devices and waste water pools, applied in chemical instruments and methods, water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems affecting equipment health, paralysis of production lines, pump evacuation, etc., to reduce equipment maintenance. Cost, reduce equipment failure rate, ensure normal use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

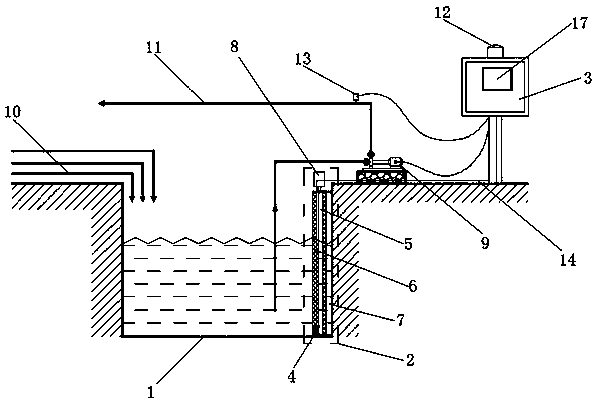

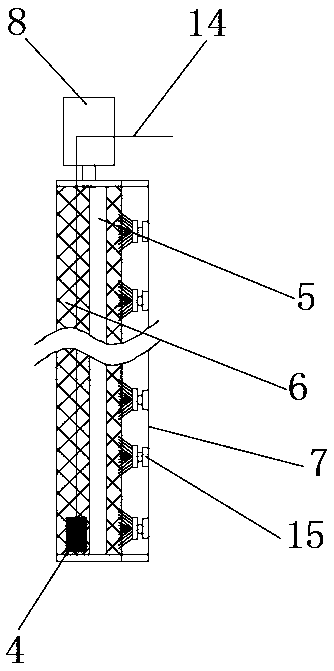

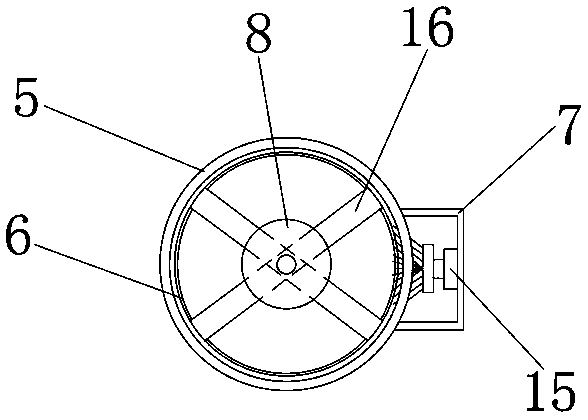

[0025] Such as Figure 1-3 As shown, a waste water pool anti-evacuation device includes a waste water pool 1, an anti-evacuation protection part 2 and a control cabinet 3; the waste water pool 1 is provided with a water inlet pipe 10 and an outlet pipe 11; the water outlet pipe 11 is connected to a water pump 9. The anti-evacuation protection part 2 includes a liquid level transmitter 4, a grid bracket outer cylinder 5, a protection mesh cylinder 6 and a cleaning chamber 7; the grid bracket outer cylinder 5 is arranged in the waste water pool 1; the The protective mesh cylinder 6 is set in the outer cylinder 5 of the grid support, and the top is connected with a cleaning motor 8; the cleaning chamber 7 is arranged on the side of the outer cylinder 5 of the grid support; A row of cleaning brushes 15 is provided; the brush heads of the cleaning brushes 15 penetrate into the protection net cylinder 6; the liquid level transmitter 4 is arranged at the bottom of the protection net ...

Embodiment 2

[0031] The difference between this embodiment and Embodiment 1 is that: the control cabinet 3 is provided with an alarm 12 and a control panel 17 . The alarm 12 sends out an audible / optical alarm when the equipment fails or the water level is abnormal; the control panel 17 is used to input control information such as high / low liquid level setting values, and can call to view relevant information of the device.

[0032] The usage method of this embodiment is the same as that of Embodiment 1.

Embodiment 3

[0034] The difference between this embodiment and embodiment 2 is that: the bottom of the grid bracket outer cylinder 5 contacts the bottom of the waste water pool 1 , and the top passes through the top of the waste water pool 1 . The bottom of the protective net cylinder 6 is also close to the bottom of the waste water pool 1, which can sense the liquid level in the waste water pool 1 more accurately.

[0035] The usage method of this embodiment is the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com