Large-sized glass ceramic board painting color baking process

A glass-ceramic, large-scale technology, which is applied in the field of glass and ceramics, can solve problems such as deformation, inability to settle the color painting picture, color difference between the center and the edge of the plate painting, etc., and achieve the effect of clear picture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

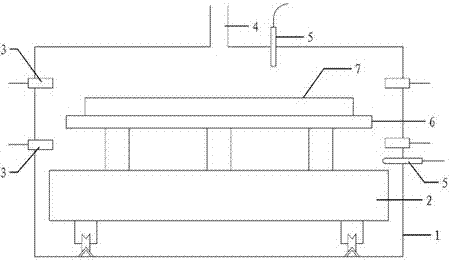

[0021] Examples: (1) Kiln design and production

[0022] The kiln includes a kiln body, a kiln car, a heating gun, an exhaust chimney, and a temperature detector;

[0023] The heating gun is connected to the LPG pipeline and uses LPG as heating energy; the exhaust chimney is used for the exhaust gas of the kiln, and the temperature detector is used to detect the temperature; the kiln car is equipped with a kiln plate (heat-resistant spar kiln plate) for supporting glass Ceramic plate painting

[0024] (2) Baked color

[0025] A. Place 12 square meters (length 6 meters, width 2 meters) single-sided large-scale glass ceramic plate painting on the kiln plate of the kiln car, the glass ceramic plate painting face up, the non-color painting side Face down

[0026] B. Push the kiln car with glass ceramic plate painting into the kiln body;

[0027] C. Ignite the heating gun to heat the kiln; the first heating time of the kiln is 61 hours, and the maximum temperature is controlled between 745℃...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com