Oil filling port box assembly

A fuel filler and assembly technology, which is applied in the field of auto parts manufacturing, can solve the problems of difficult assembly, poor sealing between the fuel filler box and fuel pipe, and lack of aesthetics, and achieves the effect of simple profile and avoiding poor sealing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to further explain the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings.

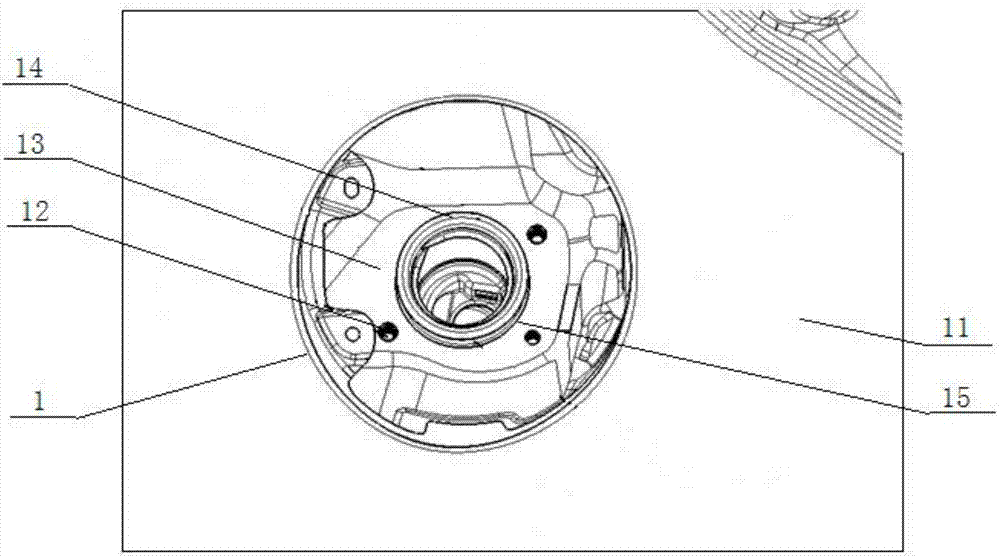

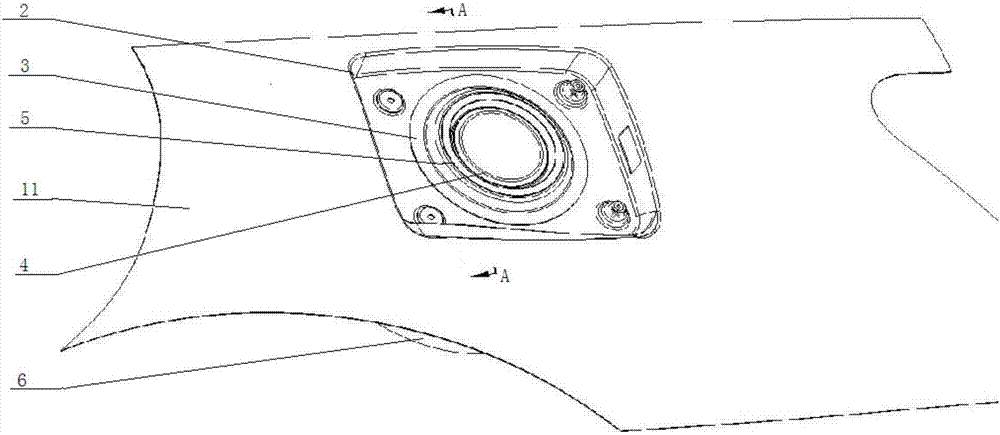

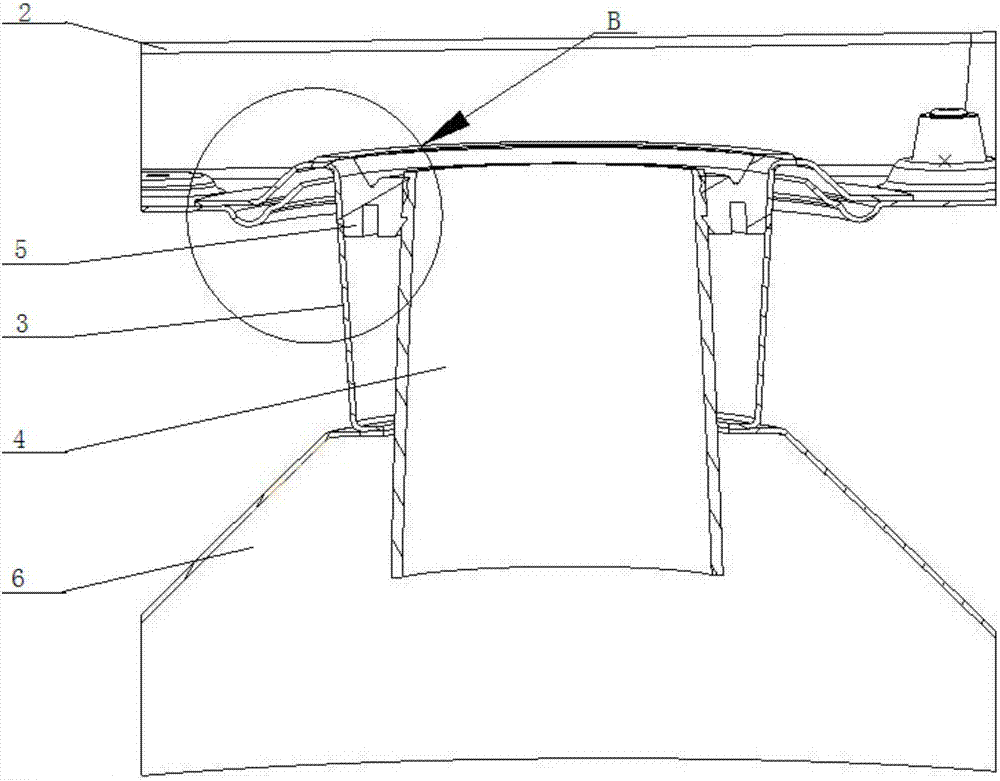

[0029] see Figure 2-Figure 4 , the fuel filler box assembly shown includes a fuel filler box 2, a fuel filler pipe 4, a fuel filler pipe guide sleeve 3 and a fuel filler pipe constraint sleeve 5;

[0030] see Figure 5 , the edge of the oil inlet at the bottom of the fuel filler box 2 is provided with an upwardly turned convex edge 21, and four puppet welding points 22 and four extrusion grooves 23 are arranged alternately at the edge close to the oil inlet;

[0031] see Image 6 , the fuel pipe guide sleeve 3 is a tubular member, the upper end is turned outward to form a rib 31, the beveled edge 32 of the rib and the outer edge 33 of the rib, and the lower end is turned inward to form a ring-shaped base 34;

[0032] see Figure 7 , the upper part of the outer wall 41 of the oil filling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com