Method for producing oligopeptide for feed from intestinal residues

A technology of oligopeptides and intestinal residues, which is applied in animal feed, animal feed, applications, etc., can solve the problems of no pretreatment of intestinal residues, increase energy consumption, and affect enzymatic hydrolysis efficiency, so as to increase product competitiveness and reduce Product cost, the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

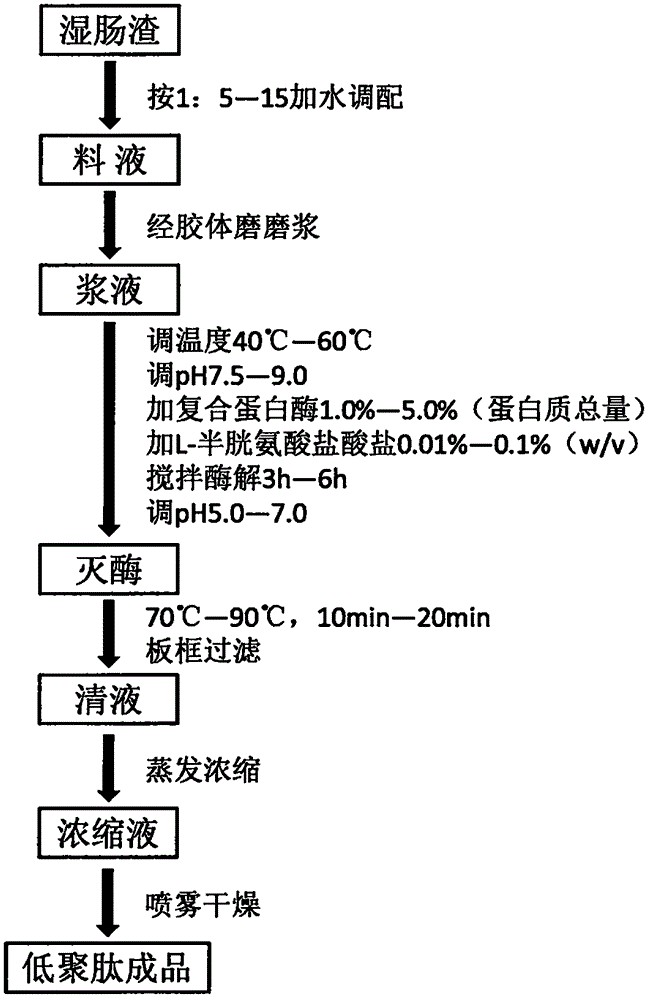

[0037] Specific implementation mode one: please refer to figure 1 , the specific embodiment adopts the following technical scheme: a kind of intestine dregs is the method for raw material production oligopeptide for feed, and its preparation method is:

[0038] a. Take 50g of intestinal residue, add 400ml of water, and stir to disperse;

[0039] b. Put the ingredients into the wall breaking machine and beat them into slurry;

[0040] c. Put the slurry into a beaker and heat it in a water bath to 40°C±1°C;

[0041] d. Use 10% NaOH seasoning solution pH7.5±0.1;

[0042] e. Add 0.263g of compound protease (2.5% total protein content), 0.08g of L-cysteine hydrochloride (0.08%, w / v), and stir for 3.5h;

[0043] f. The pH of the feed liquid is adjusted to 5.5;

[0044] g. Heat up to 70°C and inactivate the enzyme for 20 minutes;

[0045] h. The feed liquid was centrifuged at 4000rpm for 10min;

[0046] i. The clear liquid is concentrated to a solid content of about 35% by a ...

specific Embodiment approach 2

[0049] Specific embodiment two: the preparation method of this specific embodiment is:

[0050] 1. Get 10kg of intestinal residue, add 100kg of water, stir and disperse;

[0051] II. Grinding the ingredients into a slurry through a colloidal mill;

[0052] III. Pour the slurry into an enzymatic hydrolysis tank and heat to 45°C±1°C;

[0053] IV. The feed liquid is adjusted to pH 8.0±0.1 with 10% NaOH;

[0054] V. Add 63.12g of compound protease (3.0% total protein), 55.0g of L-cysteine hydrochloride (0.05%, w / v), and stir for 4 hours;

[0055] VI. The pH of the feed liquid is adjusted to 6.0;

[0056] VII. Heat up to 75°C and inactivate the enzyme for 15 minutes;

[0057] VIII, the feed liquid is filtered through the plate frame to get clear;

[0058] IX, the clear liquid is concentrated under reduced pressure to about 40% solid content;

[0059] X. Spray-dry the concentrate to obtain feed-grade oligopeptides.

specific Embodiment approach 3

[0060] Specific embodiment three: the preparation method of this specific embodiment is:

[0061] A. Take 100kg of intestinal residue, add 1500L of water, stir and disperse;

[0062] B. Grinding the ingredients into a slurry through a colloidal mill;

[0063] C. Pour the slurry into an enzymatic hydrolysis tank and heat to 50°C±1°C;

[0064] D. The feed liquid is adjusted to pH 8.5±0.1 with 10% NaOH;

[0065] E. Add 1.052 kg of compound protease (5.0% total protein), 1.6 g of L-cysteine hydrochloride (0.1%, w / v), and stir for 5 hours;

[0066] F. The pH of the feed liquid is adjusted to 6.5;

[0067] G. Raise the temperature of the feed liquid to 80°C, and inactivate the enzyme for 10 minutes;

[0068] H. The feed liquid is filtered through the plate frame to get clear;

[0069] 1, the clear liquid is concentrated under reduced pressure to about 50% solid content;

[0070] J. Spray-dry the concentrate to obtain feed-grade oligopeptides.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com