Polymer thin film based on cross structure conjugated molecules, and preparation method and applications thereof

A polymer film and conjugated molecule technology, which is applied to polymer films based on cross-structured conjugated molecules and their preparation and application fields, can solve the problems of poor film formation, low optical contrast, poor performance, etc., and achieve fast response. Effects of speed, high optical contrast, stable electrochemical activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The cross-conjugated molecules as shown below are used as polymerized monomers:

[0045]

[0046] Preparation of polymer films:

[0047] (1) Preparation of monomer solution: 1mM, 10ml, the solvent used is dichloromethane / acetonitrile (volume ratio 7 / 3), the electrolytic salt is tetrabutylammonium hexafluorophosphate, the concentration is 0.1M.

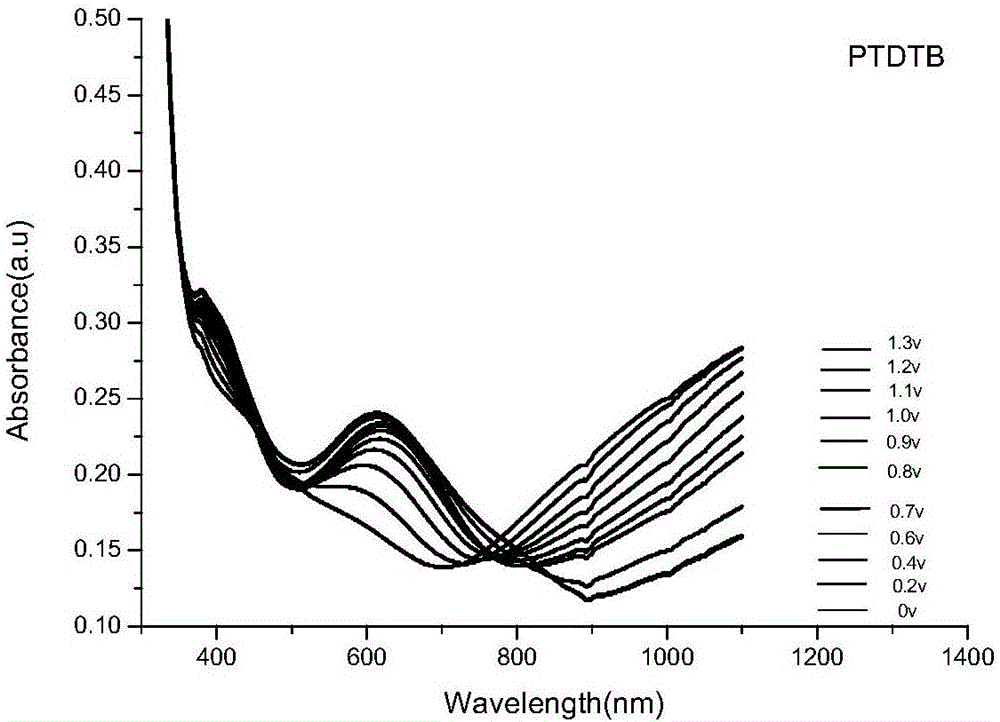

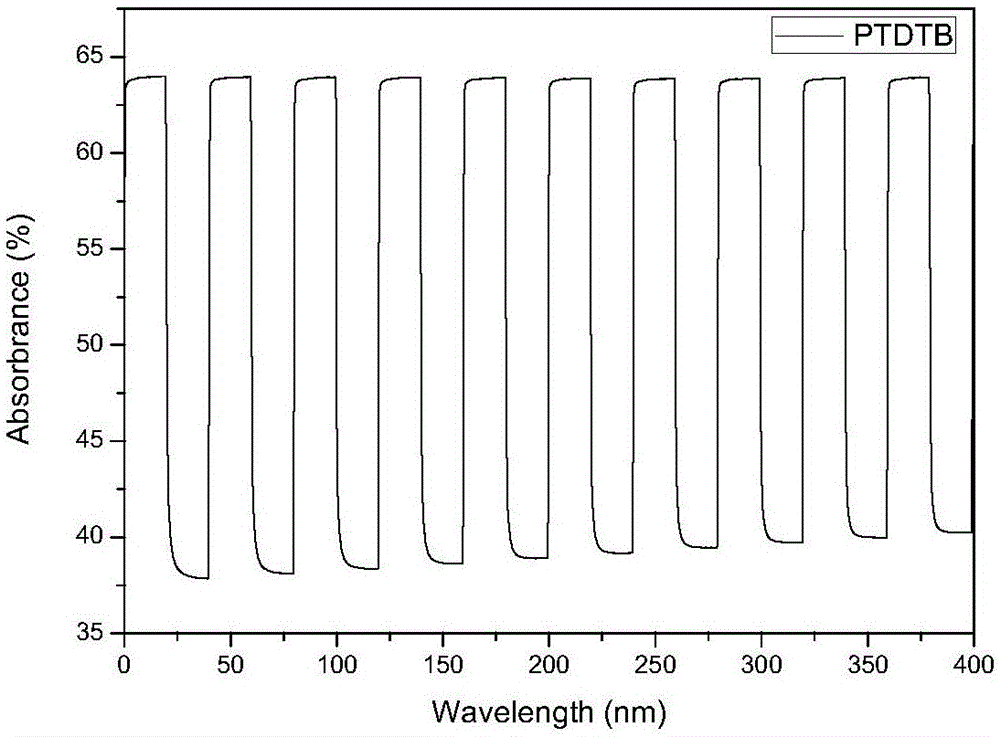

[0048] (2) Electrochemical polymerization: cyclic voltammetry, the voltage range is 0-1.3v, the number of cycles is 10 cycles, and finally a thin layer of polymer film is obtained on the surface of the ITO glass.

[0049] The spectroelectrochemical performance characterization of the obtained polymer film: the electrolyte used is 0.2M lithium perchlorate / acetonitrile, and the electrochemical workstation is used in conjunction with a UV-visible spectrophotometer. The test results are as follows figure 1 , figure 2 shown.

Embodiment 2

[0051] The cross-conjugated molecules as shown below are used as polymerized monomers:

[0052]

[0053] Preparation of polymer films:

[0054] (1) Preparation of monomer solution: 1mM, 10ml, the solvent used is dichloromethane / acetonitrile (volume ratio 7 / 3), the electrolytic salt is tetrabutylammonium hexafluorophosphate, the concentration is 0.1M.

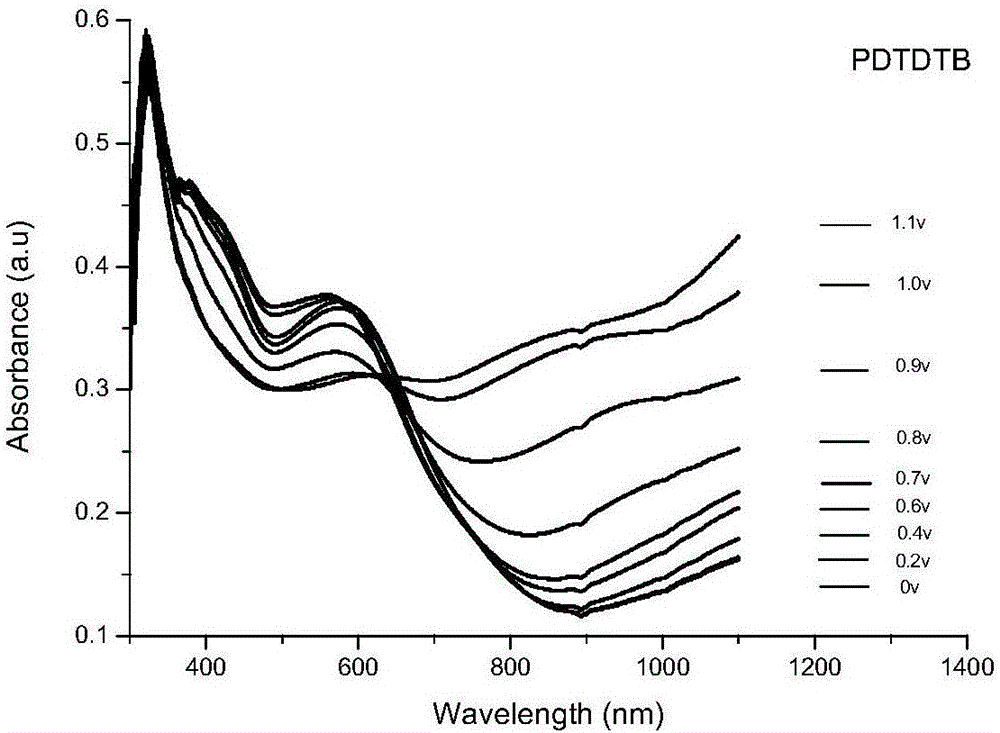

[0055] (2) Electrochemical polymerization: cyclic voltammetry, voltage range 0v-1.1v, cycle times 10 cycles, and finally a thin layer of polymer film is obtained on the surface of ITO glass.

[0056]The spectroelectrochemical performance characterization of the obtained polymer film: the electrolyte used is 0.2M lithium perchlorate / acetonitrile, and the electrochemical workstation is used in conjunction with a UV-visible spectrophotometer. The test results are as follows image 3 , Figure 4 shown.

Embodiment 3

[0058] The cross-conjugated molecules as shown below are used as polymerized monomers:

[0059]

[0060] Preparation of polymer films:

[0061] (1) Preparation of monomer solution: 1mM, 10ml, the solvent used is dichloromethane / acetonitrile (volume ratio 7 / 3), the electrolytic salt is tetrabutylammonium hexafluorophosphate, the concentration is 0.1M.

[0062] (2) Electrochemical polymerization: cyclic voltammetry, voltage range 0v-1.1v, cycle times 10 cycles, and finally a thin layer of polymer film is obtained on the surface of ITO glass.

[0063] The spectroelectrochemical performance characterization of the obtained polymer film: the electrolyte used is 0.2M lithium perchlorate / acetonitrile, and the electrochemical workstation is used in conjunction with a UV-visible spectrophotometer. The test results are as follows Figure 5 , Figure 6 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com