Emulsion type two-component interface agent

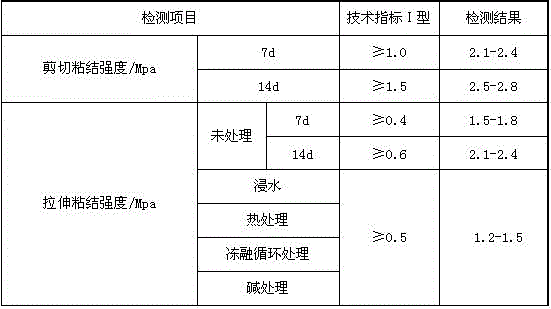

A kind of interface agent and two-component technology, which is applied in the engineering field, can solve the problems of the interface agent's toxicity to humans and the environment, low bonding strength of new and old concrete, and poor corrosion resistance, so as to achieve good durability and stable and reliable quality , good construction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1 Emulsion type two-component interface agent, this interface agent is made up of A component and B component; Wherein

[0024] Component A is calculated by weight percentage (kg / kg), consisting of 46.8% rapid hardening cement, 5.9% ordinary cement, 41.0% quartz sand, 5.8% active mineral admixture, 0.3% water reducer, 0.1 % boric acid, 0.01% hydroxypropyl methylcellulose, 0.09% analytically pure lithium carbonate;

[0025] Component B is composed of 40.5% latex, 1.1% BASF water-based defoamer, and 58.4% water by weight percentage (kg / kg).

[0026] The method of using the emulsion type two-component interface agent refers to:

[0027] Firstly, the construction base is treated. According to the different construction area and environmental conditions of the concrete base surface, the concrete base surface can be roughened by sand blasting, high-pressure water flushing, angle grinder grinding and chiseling; Foreign matter such as milk skin, loose particles, a...

Embodiment 2

[0029] Embodiment 2 Emulsion type two-component interface agent, this interface agent is made up of A component and B component; Wherein

[0030] Component A is calculated by weight percentage (kg / kg), consisting of 49.7% rapid hardening cement, 6.3% ordinary cement, 37.3% quartz sand, 6.2% active mineral admixture, 0.2% water reducer, 0.2 % boric acid, 0.01% hydroxypropyl methylcellulose, 0.09% analytically pure lithium carbonate;

[0031] Component B is composed of 36.1% latex, 1.1% BASF water-based defoamer, and 62.8% water in terms of weight percentage (kg / kg).

[0032] The method of using the emulsion type two-component interface agent refers to:

[0033] Firstly, the construction base is treated. According to the different construction area and environmental conditions of the concrete base surface, the concrete base surface can be roughened by sand blasting, high-pressure water flushing, angle grinder grinding and chiseling; Foreign matter such as milk skin, loose par...

Embodiment 3

[0035] Embodiment 3 Emulsion type two-component interface agent, this interface agent is made up of A component and B component; Wherein

[0036] Component A is calculated by weight percentage (kg / kg), consisting of 55.8% rapid hardening cement, 37.3% quartz sand, 6.2% active mineral admixture, 0.4% water reducer, 0.2% boric acid, 0.01% Hydroxypropyl methylcellulose and 0.09% analytically pure lithium carbonate are mixed;

[0037] Component B is composed of 33.3% latex, 1.2% BASF water-based defoamer, and 65.5% water by weight percentage (kg / kg).

[0038] The method of using the emulsion type two-component interface agent refers to:

[0039] Firstly, the construction base is treated. According to the different construction area and environmental conditions of the concrete base surface, the concrete base surface can be roughened by sand blasting, high-pressure water flushing, angle grinder grinding and chiseling; Foreign matter such as milk skin, loose particles, and exposed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com