Three-dimensional TiO2/ZnO heterojunction array synthesis method

A synthesis method, a technology of heterojunction, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, chemical/physical processes, etc., can solve the disadvantages of large-scale promotion, complex preparation process, and expensive equipment. and other problems, to achieve the effect of being conducive to large-scale production, simple process, and improving capture capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

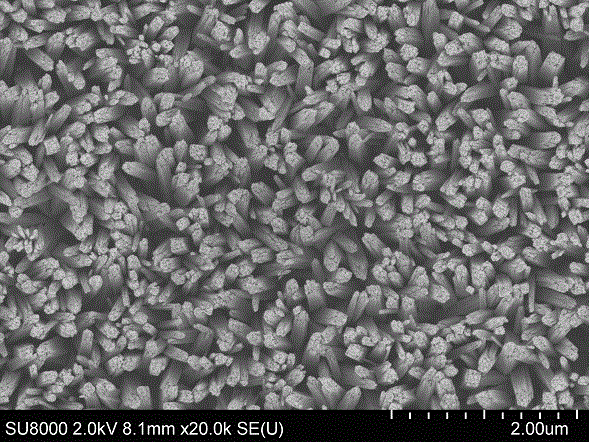

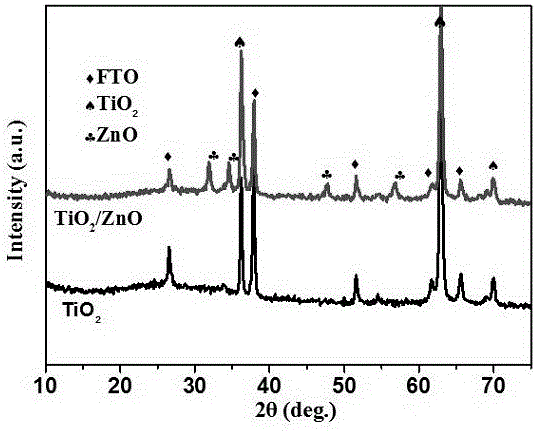

[0018] (1) Add 0.8mL tetrabutyl titanate to a mixed solution of 24mL deionized water, 22mL concentrated hydrochloric acid (37wt%) and 2mL acetic acid, and stir until the solution is clear to obtain a precursor solution, then transfer the precursor solution to water Put clean FTO conductive glass in the thermal reaction kettle, react with water at 150°C for 20h, cool down to room temperature naturally, take out the sample, clean it and dry it, then place it in a muffle furnace and anneal at 450°C for 30min to increase the crystallinity get one-dimensional TiO 2 nanorod arrays;

[0019] (2) TiO obtained in step (1) 2 Nanorod arrays were soaked in 50mL ethanol solution dissolved with zinc acetate and diethanolamine, wherein the molar concentration of zinc acetate was 0.12mol / L, and the volume fraction of diethanolamine was 1%, soaked at room temperature for 10min, and then the samples were taken out and placed Calcined in a muffle furnace at 400°C for 30 minutes to obtain TiO c...

Embodiment 2

[0023] (1) Add 0.8mL tetrabutyl titanate to a mixed solution of 24mL deionized water, 22mL concentrated hydrochloric acid (37wt%) and 2mL acetic acid, and stir until the solution is clear to obtain a precursor solution, then transfer the precursor solution to water Put clean FTO conductive glass in the thermal reaction kettle, react with water at 150°C for 20h, cool down to room temperature naturally, take out the sample, clean it and dry it, then place it in a muffle furnace and anneal at 450°C for 30min to increase the crystallinity get one-dimensional TiO 2 nanorod arrays;

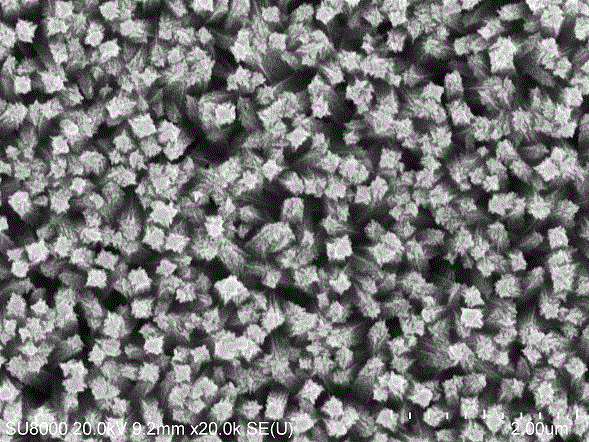

[0024] (2) TiO obtained in step (1) 2 Nanorod arrays were soaked in 50mL ethanol solution dissolved with zinc acetate and diethanolamine, wherein the molar concentration of zinc acetate was 0.12mol / L, and the volume fraction of diethanolamine was 1%, soaked at room temperature for 30min, and then the samples were taken out and put Calcined in a muffle furnace at 400°C for 30 minutes to obtain TiO cove...

Embodiment 3

[0027] (1) Add 0.8mL tetrabutyl titanate to a mixed solution of 24mL deionized water, 22mL concentrated hydrochloric acid (37wt%) and 2mL acetic acid, and stir until the solution is clear to obtain a precursor solution, then transfer the precursor solution to water Put clean FTO conductive glass in the thermal reaction kettle, react with water at 150°C for 20h, cool down to room temperature naturally, take out the sample, clean it and dry it, then place it in a muffle furnace and anneal at 450°C for 30min to increase the crystallinity get one-dimensional TiO 2 nanorod arrays;

[0028] (2) TiO obtained in step (1) 2Nanorod arrays were soaked in 50mL ethanol solution dissolved with zinc acetate and diethanolamine, wherein the molar concentration of zinc acetate was 0.12mol / L, and the volume fraction of diethanolamine was 1%, soaked at room temperature for 20min, and then the samples were taken out and placed Calcined in a muffle furnace at 400°C for 30 minutes to obtain TiO co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com