Production method and equipment for back-surface cutting counterpoint line of glass passivation silicon wafer

A production method and glass passivation technology, which are applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of cumbersome positioning line process, labor consumption, low production capacity, etc., so as to reduce production costs and operation time, improve Production precision, reduce the effect of out-of-center

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

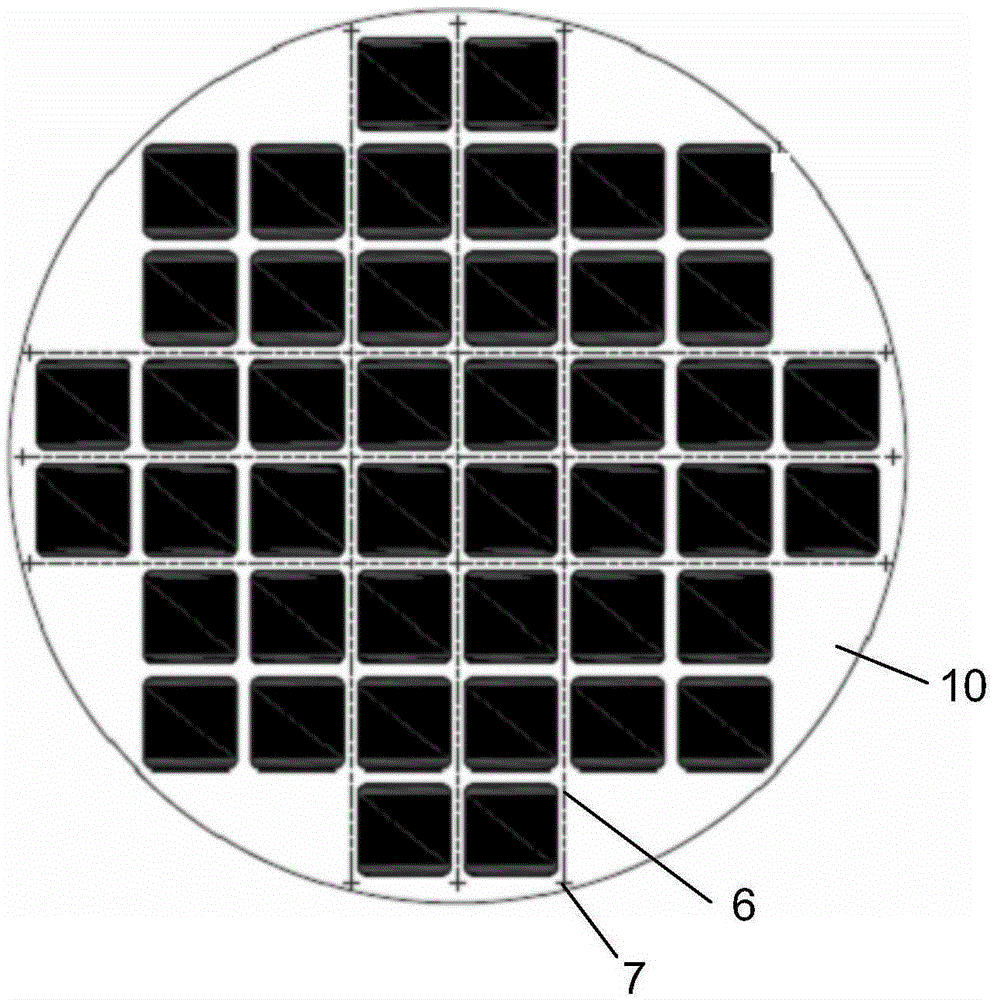

[0051]First, a silicon wafer is grabbed by a robot arm from the wafer magazine by vacuum adsorption, and the silicon wafer is sent under the lens of the imaging device through mechanical movement. The imaging device takes pictures and recognizes the angle information of the cutting line. Make the channel of the silicon wafer approximately parallel to the imaging device. Accurately identify the left point and the right point of the trench, and gradually increase the distance between the left and right points until the two ends of the same trench are identified, and the blank areas at the two ends of the trench and without invalid chips are respectively regarded as one For the target point, use the laser to mark the "ten" figure on the corresponding target point position, and penetrate the entire silicon wafer (horizontal), rotate the silicon wafer 90 degrees, and continue to make a point left and a point right on the channel Accurate recognition, and gradually increase the dist...

Embodiment 2

[0053] In advance, the cross line is photo-etched on the blank area around the silicon wafer once, and the cross line is photo-etched together with the dicing line 6 when the silicon wafer is produced. Empty area, and located in the center area at the end of the cutting line.

[0054] The manipulator grabs a silicon wafer with photo-etched cross lines from the wafer magazine by vacuum adsorption, sends the silicon wafer under the lens of the imaging device through mechanical movement, and directly takes pictures of the cross on the left through the imaging device. Then take a picture of the cross on the right, and the two points are in a line, and the angle information can be calculated, and the silicon wafer channel is precisely parallel to the imaging device through the rotation of the mechanical parts. Use the laser to overlap and mark the positions of the "ten" at both ends of the channel in the lateral direction and penetrate the entire silicon wafer. There is no need to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com