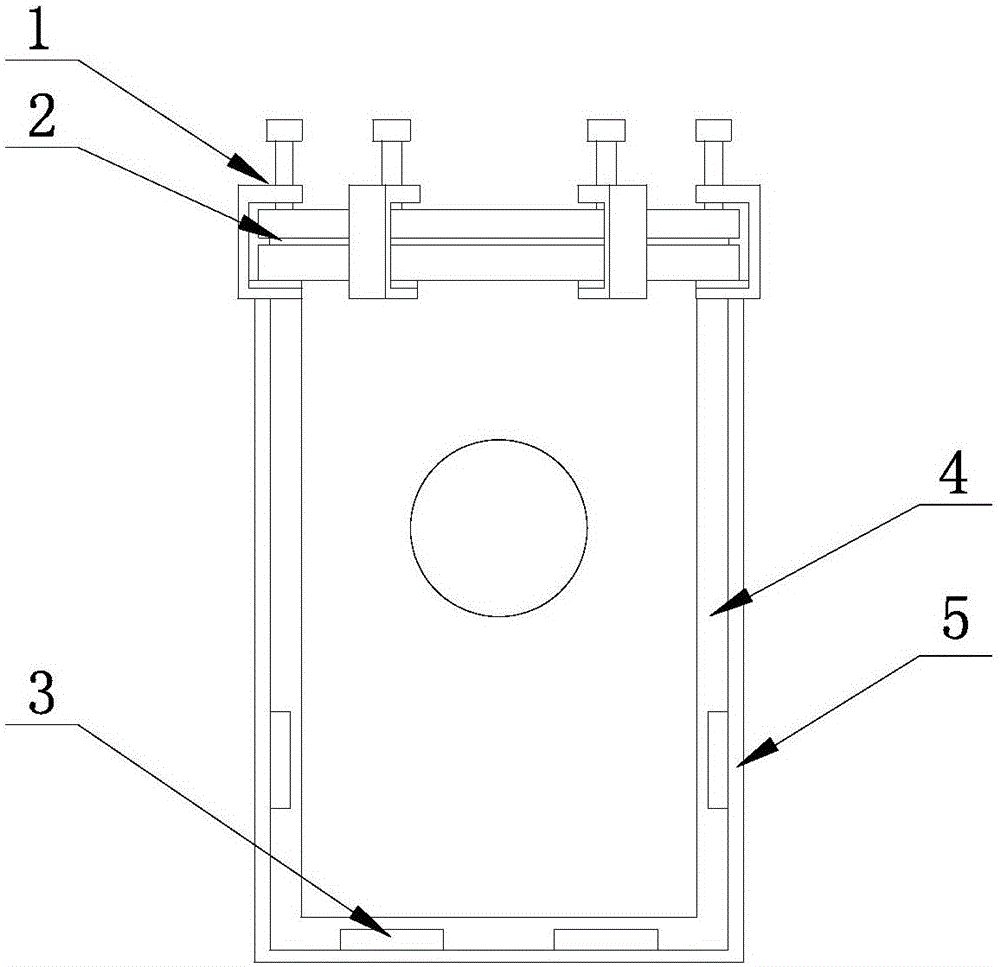

Electrochemical corrosion test apparatus and application method thereof

A test device, electrochemical technology, applied in the direction of measuring device, weather resistance/light resistance/corrosion resistance, material analysis using acoustic emission technology, etc., can solve the problem of inability to simulate acoustic emission detection and electrochemical detection, and inability to test tiny samples , the size of the tested sample is large, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

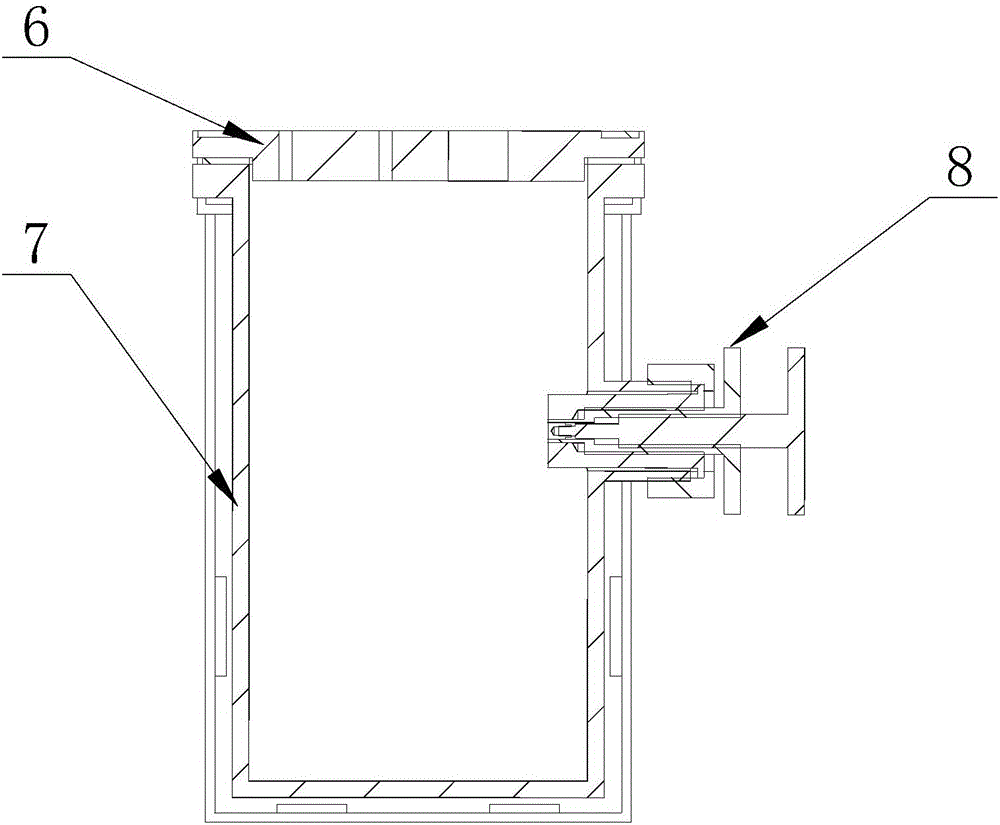

[0087] The present invention will be further explained below in conjunction with the drawings and embodiments, but it should not be understood as a limitation to the present invention.

[0088] The sample fixture used for electrochemical corrosion test, namely the above attachment Figure 8 The sample mounting device in, consists of a stepped threaded waveguide rod, a first-stage sleeve, a second-stage sleeve, a third-stage sleeve and a sealing ring. The stepped-threaded waveguide rod, a first-stage sleeve, a second-stage sleeve, and a third-stage sleeve The barrel and the sealing ring are coaxially arranged, wherein: the stepped threaded waveguide rod is provided with a first external thread and a second external thread, and the first external thread is connected with the internal thread of the first-level sleeve so that the front end of the stepped threaded waveguide rod is placed In the first cavity and the second cavity of the first-level sleeve, the second external thread is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com