Multi-plate wet clutch oil pressure control system of hydrodynamic transmission

A technology of wet clutch and hydraulic transmission, applied in the direction of transmission control, elements with teeth, fluid pressure actuating devices, etc., can solve the problems of high maintenance cost, easy damage, and many influencing factors, and achieve high maintenance cost. , The effect of reducing power interruption time and less interference factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

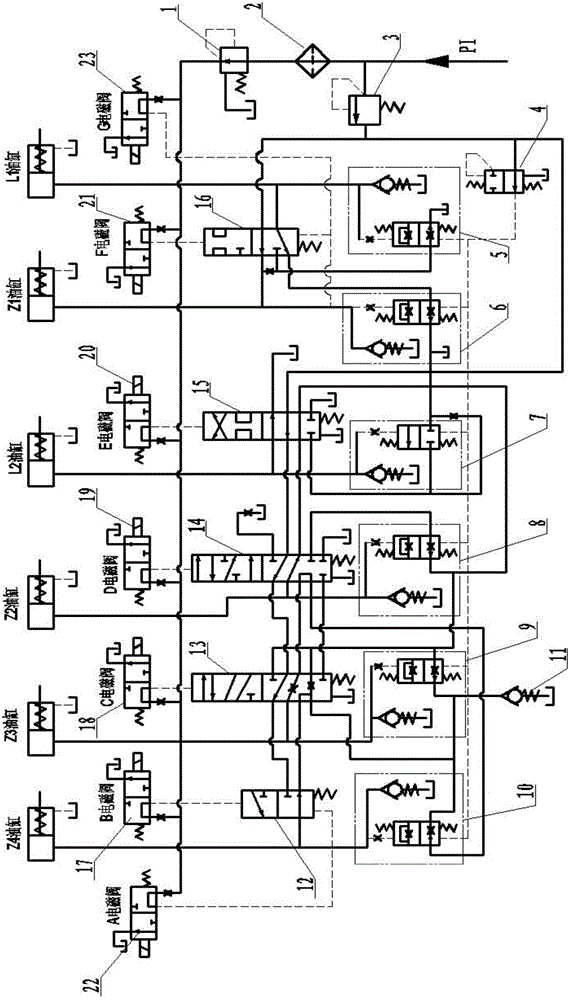

[0026] Embodiment 1: as figure 1 As shown, when the power is not on, the main oil circuit PI is divided into two circuits, one of which goes through the filter screen 2 to the electromagnetic pressure regulating valve 1, so as to supply oil to the pilot proportional solenoid valve B17 ~ pilot proportional solenoid valve F21, and the oil pressure enters the two-position multi-way The top of the reversing spool valve A12~two-position multi-way reversing spool valve E16, so that the spool valve core is located at the lower part, and the control oil passages of each clutch are in the state of draining oil; the other way goes to the priority valve 3, passes through two Pass reversing slide valve A12 to two-position multi-pass reversing slide valve E16, ready to supply oil to the clutch oil cylinder.

[0027] After the power is turned on, one or two of the pilot proportional solenoid valve B17 ~ pilot proportional solenoid valve F21 is energized, and the corresponding two-position m...

Embodiment 2

[0035] Embodiment 2: A solenoid valve is added at the bottom of the slide valve spool to realize the locking gear function, such as figure 2 As shown, solenoid valve A22 and solenoid valve G23 are added, and the power is energized as shown in Table 4, which can realize the function of locking the gear when the power is suddenly cut off during work. According to the gear requirements of the transmission, the number of pilot solenoid valves can be reduced to reduce the gear.

[0036] Table 4

[0037]

[0038] In order to improve the response speed of each valve, the spool of each reversing spool valve is made of lighter aluminum alloy material, and the surface of the spool is hard anodized to improve the wear resistance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com