Fuel pump valve element

A valve element and fuel pump technology, applied in engine elements, fuel injection pumps, fuel injection devices, etc., can solve problems such as easy turbulence, reduce processing requirements, prevent radial movement, and achieve the effect of unidirectional flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

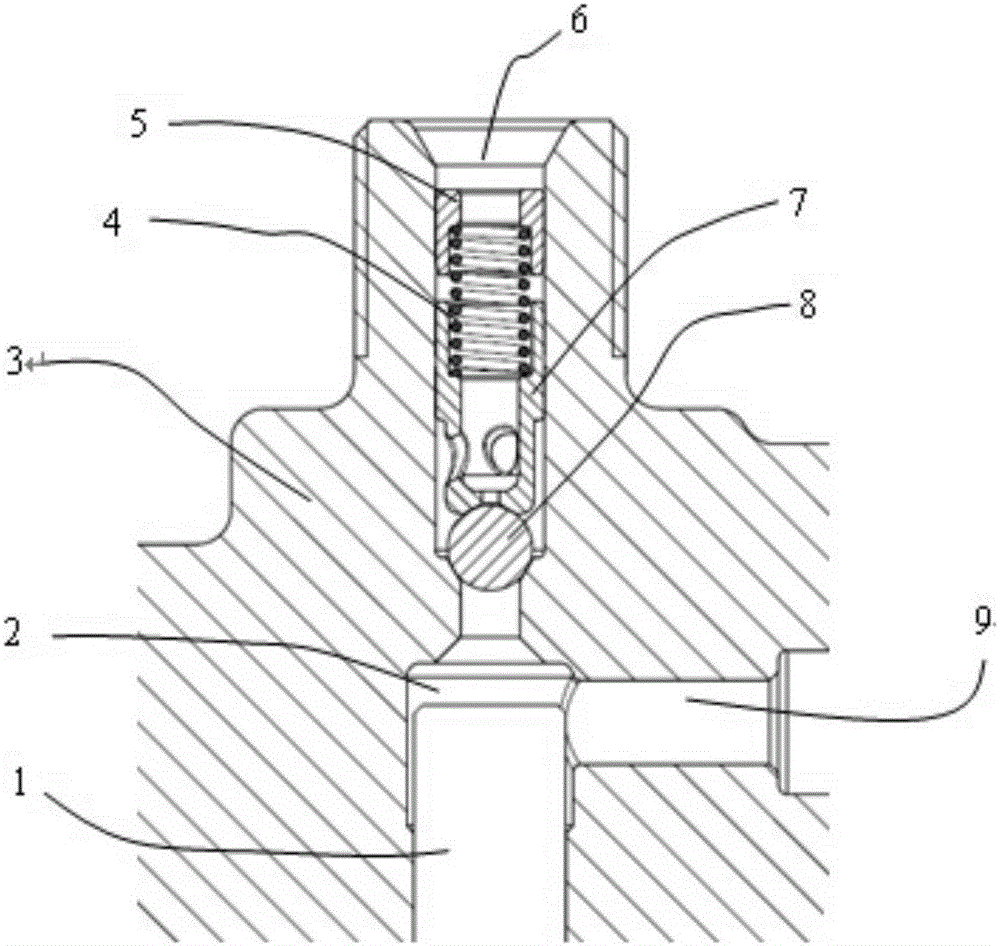

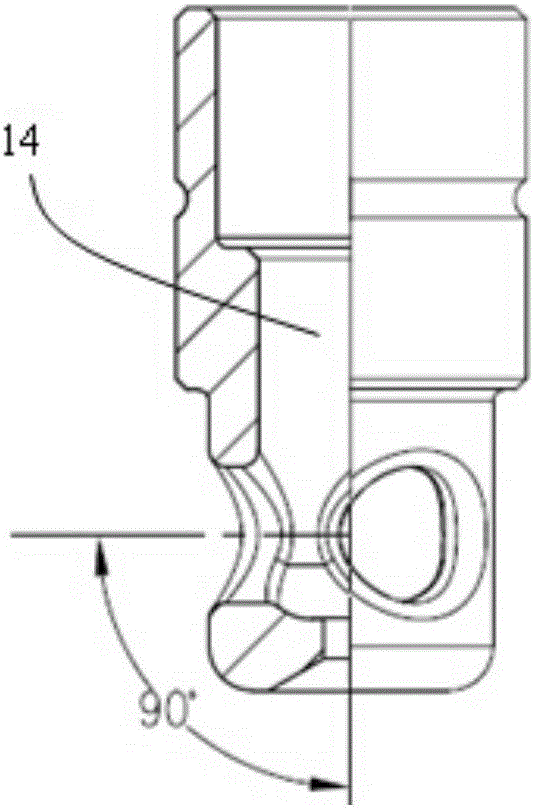

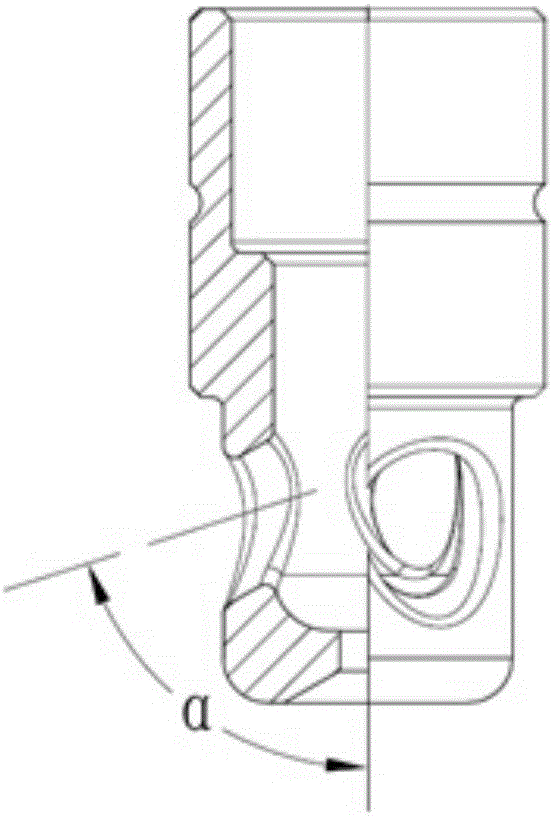

[0012] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0013] Figure 1~4 , including plunger 1, plunger cavity 2, plunger sleeve 3, return spring 4, oil outlet valve spring seat 5, oil outlet passage 6, guide sleeve 7, spherical valve element 8, oil inlet passage 9, conical surface 10. The second hole 11, the first hole 12, the upper section of the guide sleeve 13, the axial hole 14, the stepped round hole 15, etc.

[0014] Such as Figure 1~4 As shown, the present invention is a fuel pump valve element, including a plunger sleeve 3, and the plunger sleeve 3 is provided with a plunger chamber 2 and an oil outlet passage 6 along the axial direction, and the gap between the plunger chamber 2 and the oil outlet passage 6 The space is connected through the stepped round hole 15, the oil outlet passage 6 is provided with a guide sleeve 7, a spherical valve element 8 is provided between the lower e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com