A Forced Exhaust Gas Injection System to Suppress Pre-ignition and Knock

A technology of exhaust gas injection and detonation, which is applied in the direction of charging system, exhaust gas recirculation, machine/engine, etc., can solve the problems of increasing fuel consumption, achieve early combustion and detonation suppression, fast response, and reduce O2 concentration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing, the present invention will be further described:

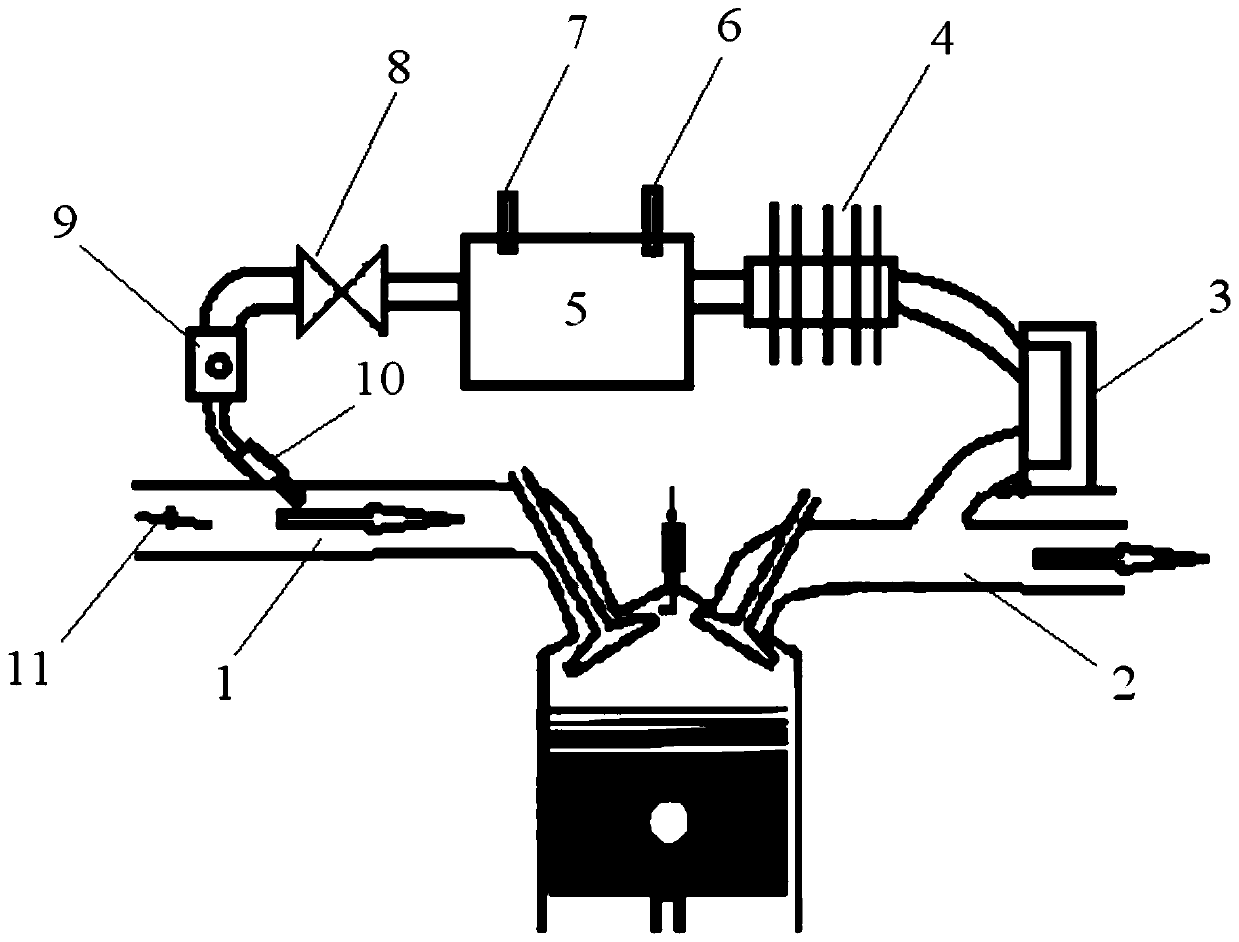

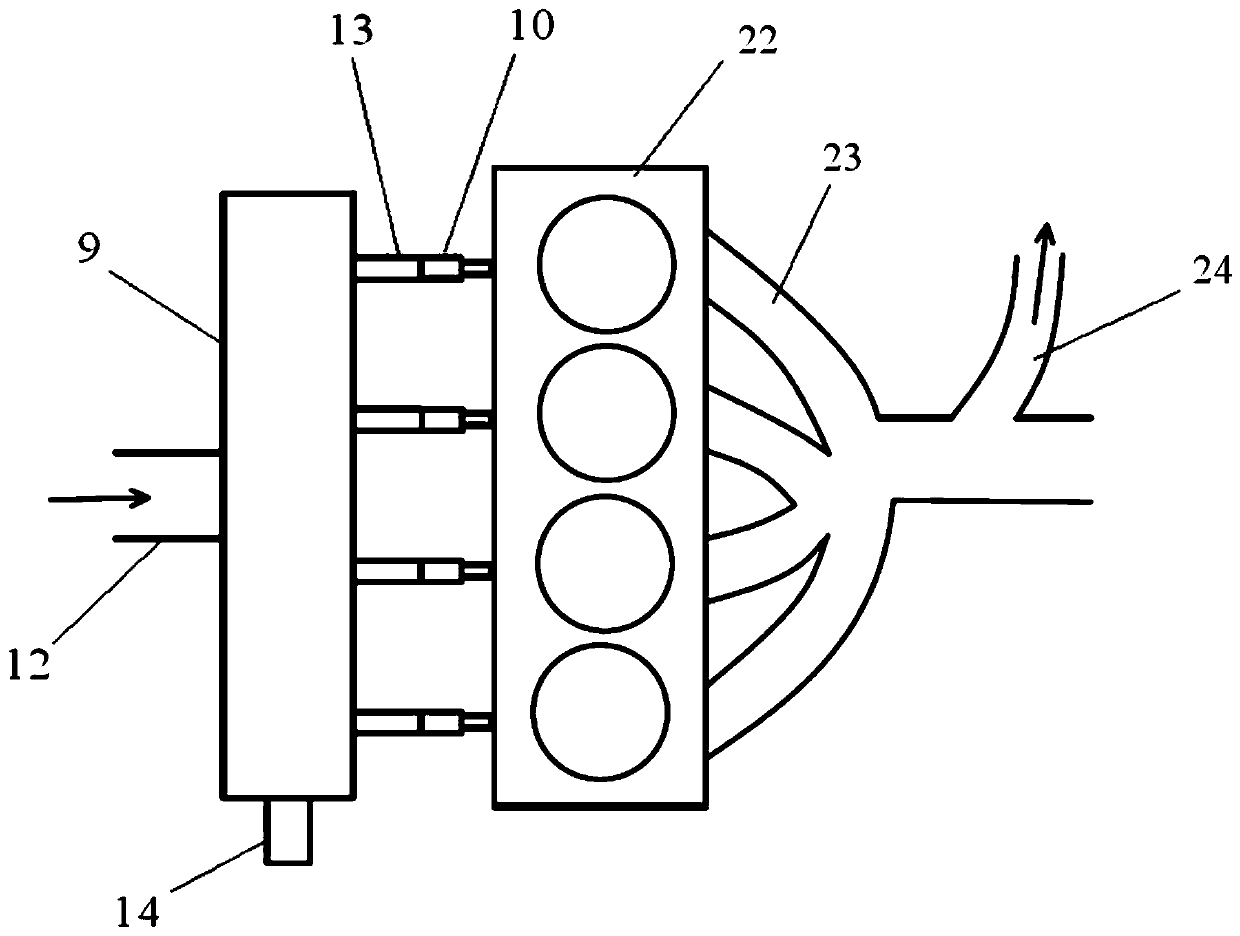

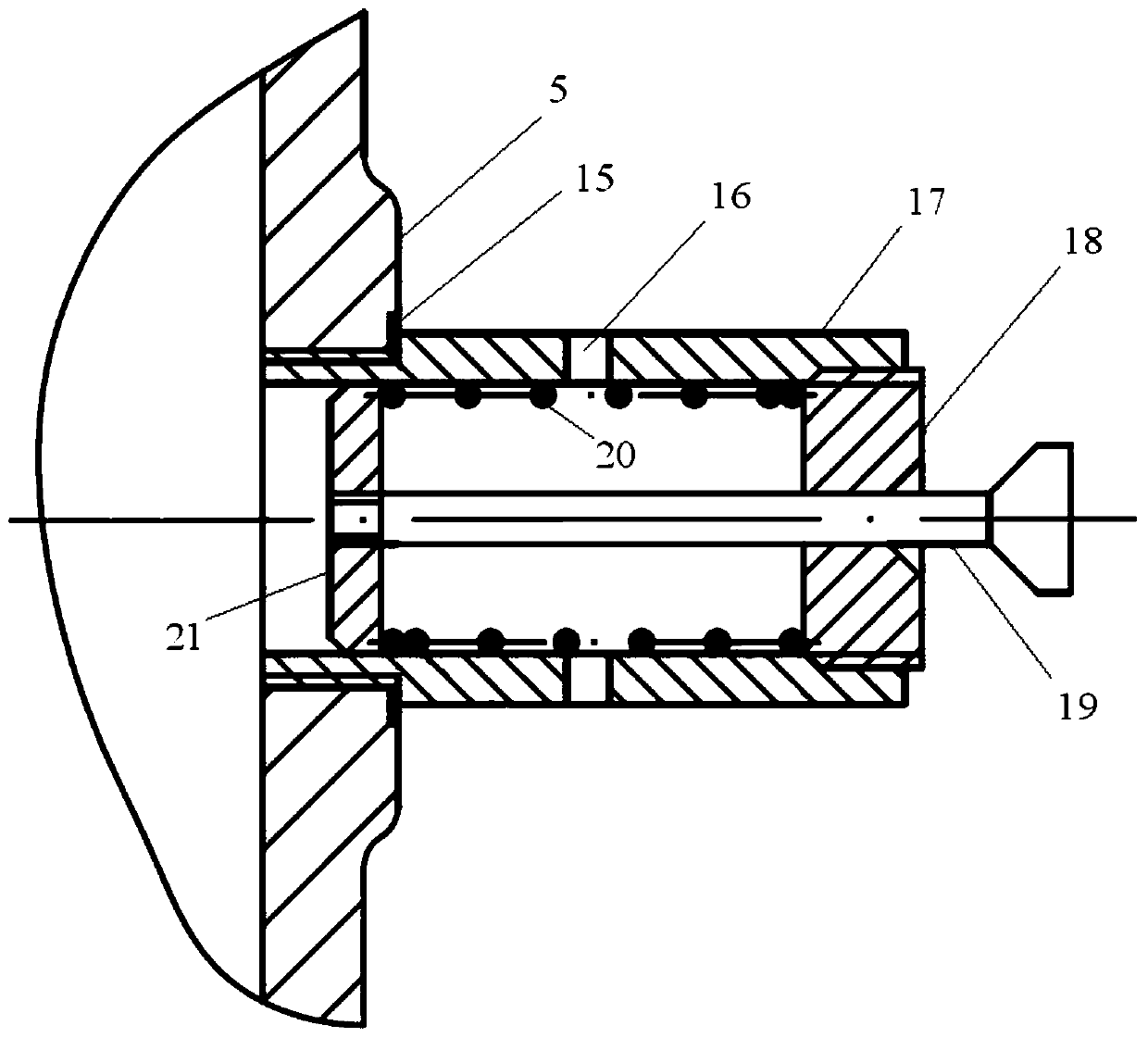

[0021] Such as figure 1 As shown, a forced exhaust gas injection system for suppressing pre-ignition and knocking is arranged between the intake port 1 and the exhaust pipe 2 of the engine, and the exhaust pipe 2 is connected to the electric compressor 3 by setting an exhaust gas leading pipe. The electric compressor 3 is connected to the intercooler 4, the gas storage tank 5, the pressure reducing valve 8, the gas collection box 9, the air injection valve 10 and the air inlet 1 in sequence through pipelines, and the gas storage tank 5 is provided with a pressure sensor 6 and a pressure Stabilizer 7; use the electric compressor 3 to compress the exhaust gas drawn from the exhaust pipe 2, and the compressed gas is cooled by the intercooler and stored in the gas storage tank 5; the gas in the gas storage tank 5 passes through the pressure reducing valve 8 enters the exhaust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com