Dynamic sealing grouting cover and using method thereof

A technology of dynamic sealing and sealing ring, which is applied in the direction of construction, building structure, and building material processing, etc. It can solve the problems of poor sealing performance and inconvenient use, and achieve good use effect, convenient turnover and use without spraying effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

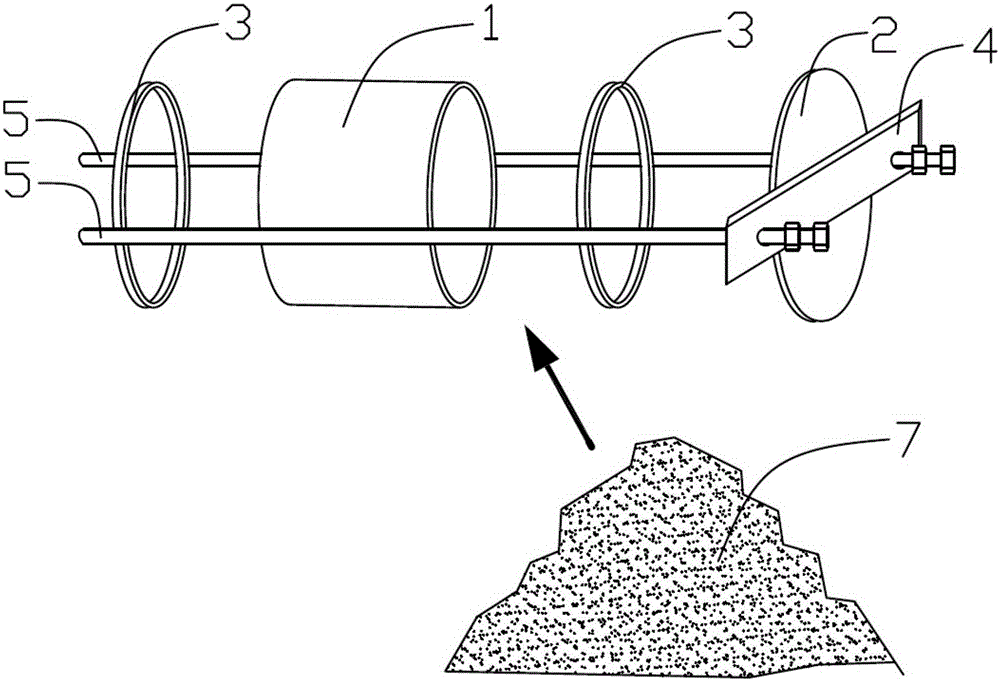

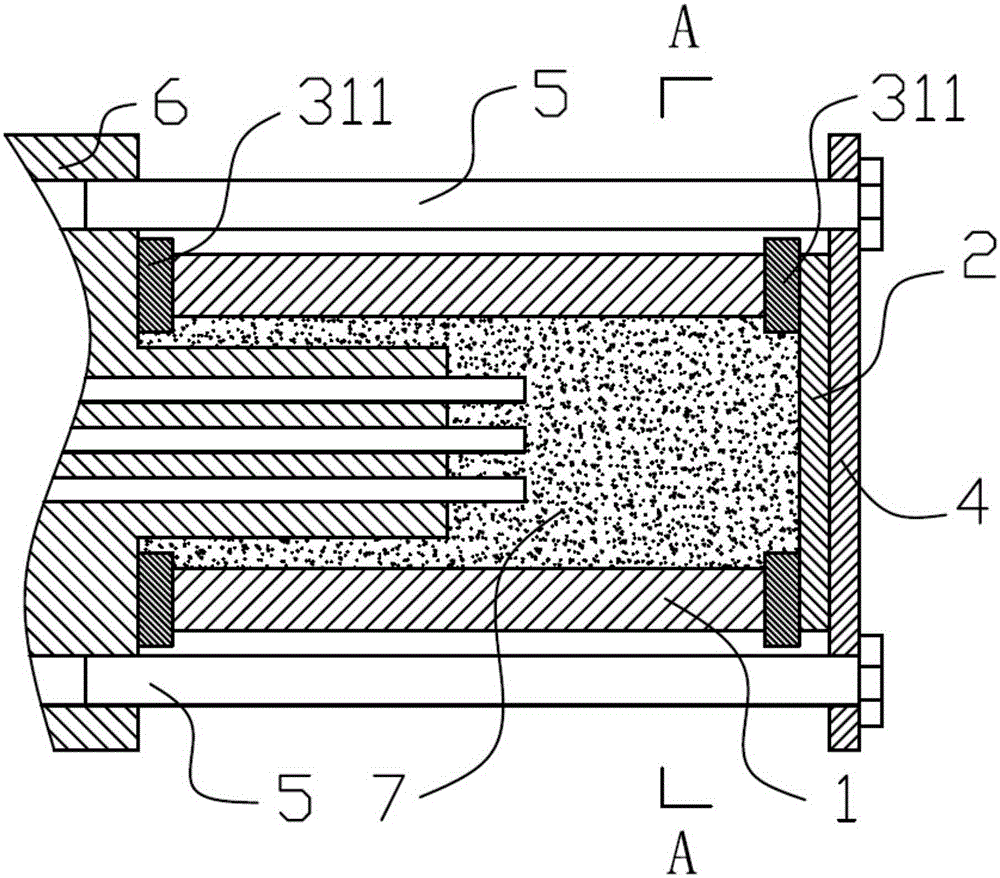

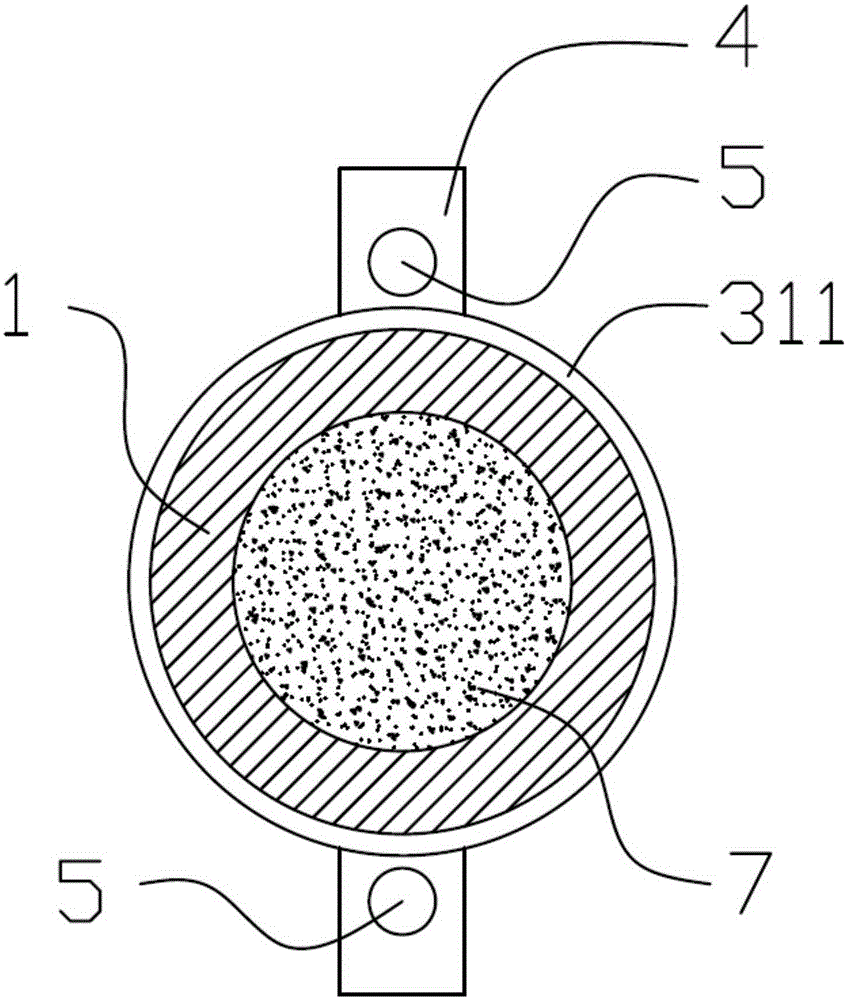

[0054] Such as Figure 1 ~ Figure 4 As shown, a dynamic sealing grouting hood includes a straight pipe 1, a cover plate 2 is arranged at one end of the straight pipe 1, a sealing member 3 is arranged between the straight pipe 1 and the cover plate 2, and the cover The length of the plate 2 in the radial direction of the straight pipe 1 is greater than or equal to the outer diameter of the straight pipe 1, and the end surface of the cover plate 2 away from the straight pipe 1 is provided with a fastener 4, the The fastener 4 is connected with the beam body pre-embedded anchor backing plate 6 using bolts 5, and the beam body pre-embedded anchor backing plate 6 cooperates with the end of the straight pipe 1 away from the cover plate through the sealing part 3, Set dry hard mortar 7 in the airtight space formed by the straight pipe 1, the cover plate 2, the seal 3 and the beam body pre-embedded anchor plate 6, and the material of the straight pipe 1 is polychlorinated The sealing...

Embodiment 2

[0057] Such as Figure 2 ~ Figure 4 As shown, in the structure as described in Embodiment 1, the sealing ring 31 is a rectangular sealing ring 311, the fastener 4 is detachably connected to the cover plate 2, and the fastener 4 is Linear type, for example, the fastener 4 can be a steel plate.

[0058] In the above scheme of the present embodiment, the sealing ring 31 is a rectangular sealing ring 311, and the type of the sealing ring 31 is a common sealing ring, which can be directly purchased or easily processed. In addition, the fastener 4 and the cover plate 2 are detachably connected, which can Make the fastener 4 and the cover plate 2 relatively independent, so that the damage of one of the fastener 4 and the cover plate 2 will not affect the use of the other part, that is to say, both the fastener 4 and the cover plate 2 When one of the parts is damaged, the other part can be used normally, and there is no need to replace the two parts at the same time. In addition, the...

Embodiment 3

[0060] Such as Figure 2 ~ Figure 4 As shown, in the structure as described in Embodiment 2, the thickness of the rectangular sealing ring 311 in the radial direction is greater than the thickness of the straight cylinder 1 in the radial direction, and the fastener 4 and the cover plate 2 welding.

[0061] In the above solution of this embodiment, the thickness of the rectangular sealing ring 311 along the radial direction is greater than the thickness of the straight cylinder 1 along the radial direction. It can completely cover the end faces of the two ends of the straight cylinder 1, so when the rectangular sealing ring 311 is squeezed and deformed by tightening the bolt 5, the gap between the end surfaces of the two ends of the straight cylinder 1 and the embedded anchor plate 6 of the beam body or the cover plate 2 is completely covered. Filling, like this, can have better sealing performance.

[0062] The fastener 4 is welded to the cover plate 2. In this way, the comb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com