Plate cutting device

A cutting device and plate technology, applied in the field of plate processing, can solve the problems of low processing efficiency, excessive sawdust, and complexity, and achieve the effect of fast processing, stable and fast cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Further detailed explanation through specific implementation mode below:

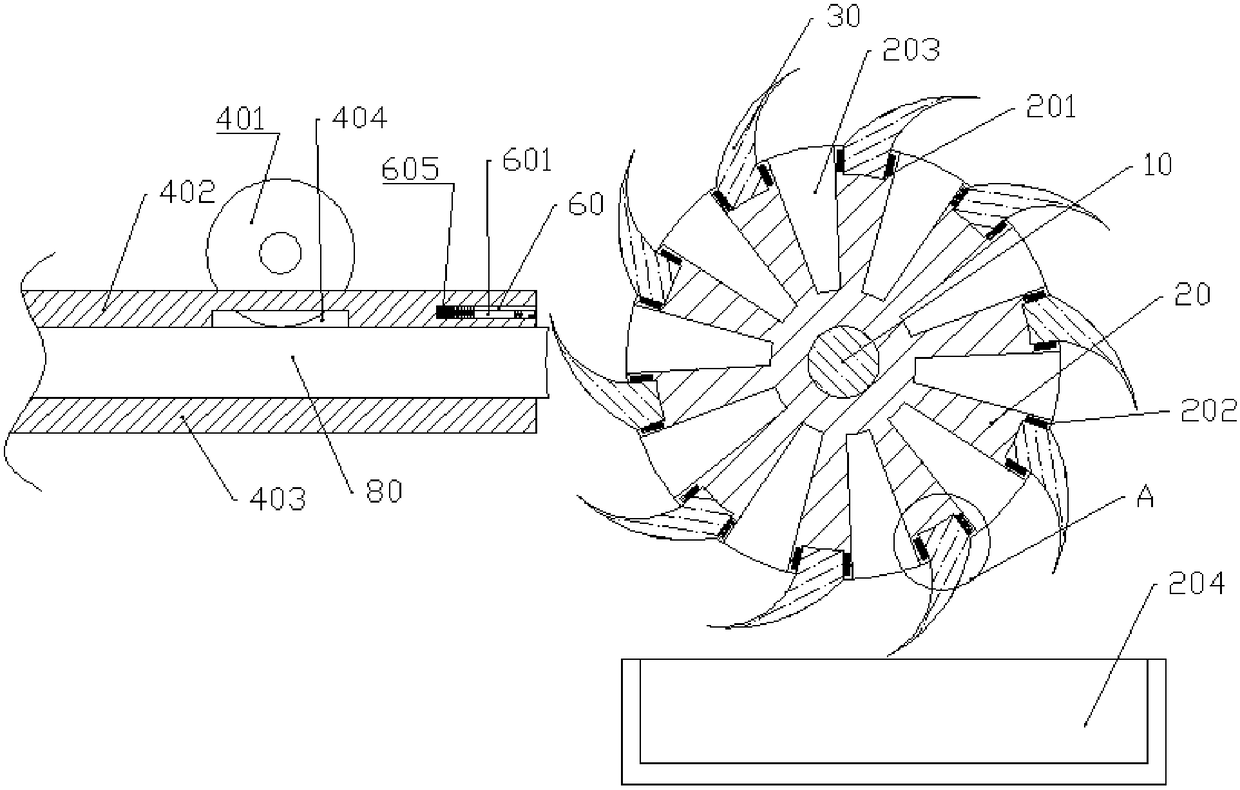

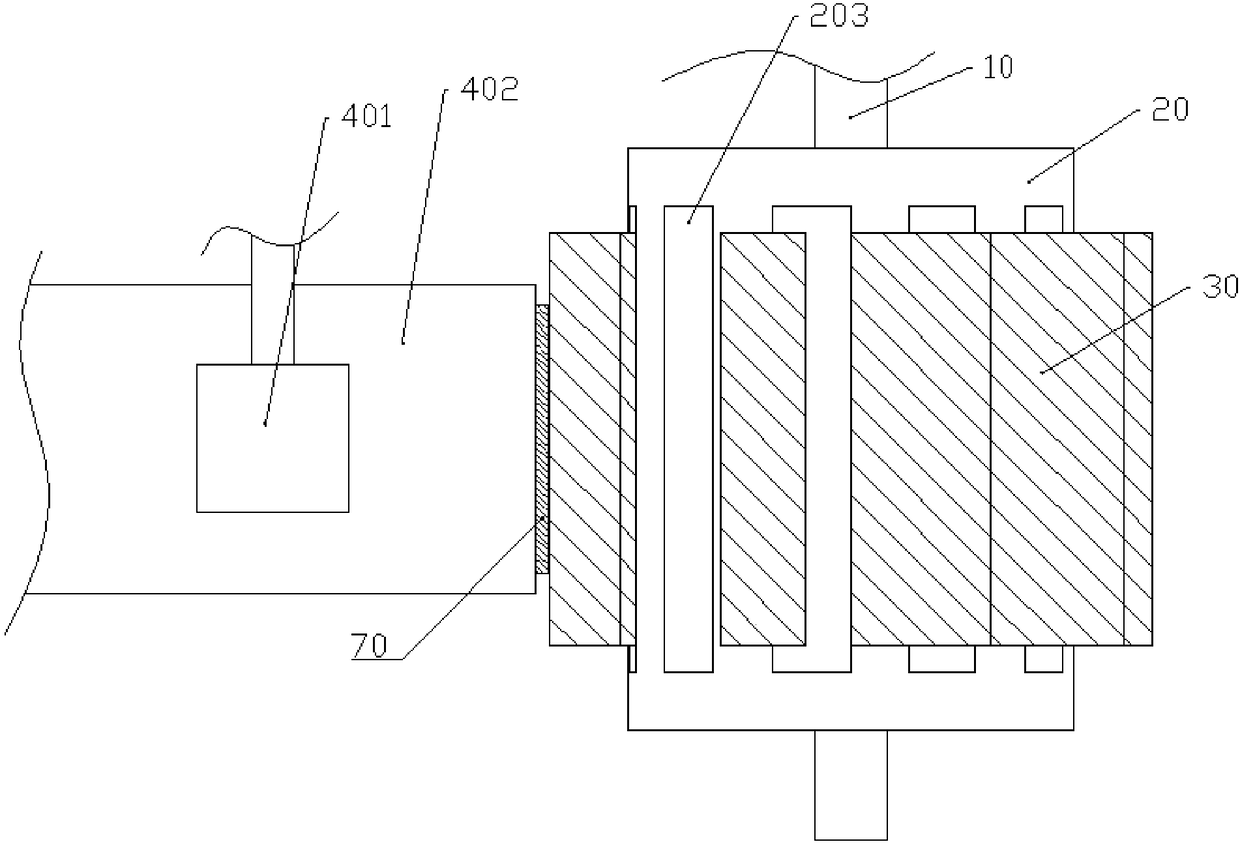

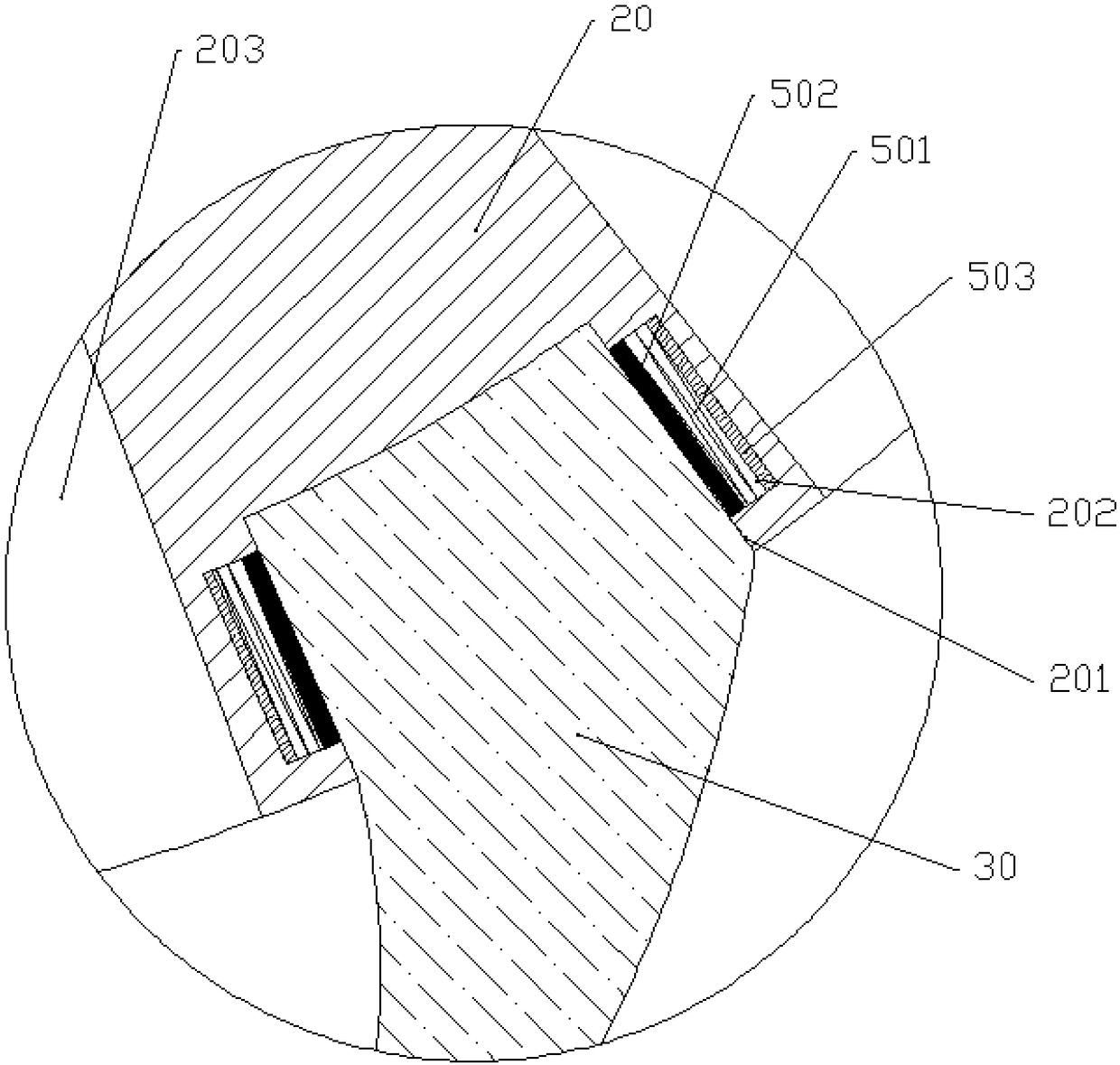

[0020] The reference numerals in the accompanying drawings of the specification include: the rotating shaft 10, the cutting roller 20, the installation groove 201, the first groove 202, the receiving groove 203, the collecting groove 204, the cutter 30, the conveying roller 401, the conveying plate 402, the fixing plate 403, Through slot 404, first compression spring 501, locking block 502, first electromagnet 503, second groove 60, first rod 601, second rod 602, contact sensor 603, second compression spring 604, second electromagnetic Iron 605, plate 70.

[0021] The embodiment is basically as attached figure 1 , attached figure 2 And attached image 3 Shown: Plate cutting device, including cutting mechanism, conveying mechanism, limit unit and ten disassembly units.

[0022] The cutting mechanism includes a cutting roller 20, a horizontally arranged rotating shaft 10 and ten cutters 30. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com