Conversion preheating device in sulfuric acid production

A technology for preheating device and sulfuric acid production, applied in the fields of sulfur compounds, inorganic chemistry, chemical instruments and methods, etc., can solve the problems of lack of personal safety, waste of a lot of time, economic losses, etc. Human injury, good operating environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

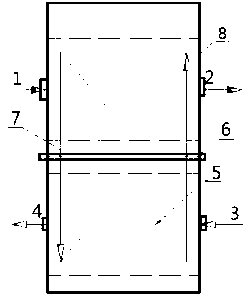

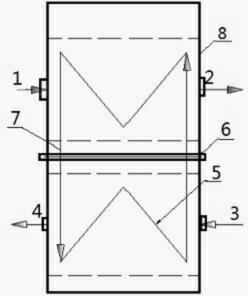

[0011] Example: Rectify the existing process gas preheating device of Wengfu Group Co., Ltd.'s 2×400,000 tons / year pyrite acid production plant, continue to use the existing high-temperature flue gas generation device, and replace the common shell-and-tube heat exchange The heat pipe heat exchanger is changed to a heat pipe heat exchanger, and the pipes with the same diameter of the inlet and outlet pipes of the process gas are connected, and one end of the heat pipe heat exchanger is extended into the high temperature flue gas channel, and the other end is extended into the process gas pipeline. It can be achieved by separating it from the process gas side with a separator. The heat pipe heat exchanger used for preheating is composed of a process gas inlet 1, a process gas outlet 2, a high temperature flue gas inlet 3, a high temperature flue gas outlet 4, a circulating heat exchange working medium 5 in the heat pipe, a partition 6, and a heat pipe heat exchanger heat pipe 7. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com