Composite floor slab based on polyphenyl granule fiber concrete sandwich insulation and construction method

A technology of fiber concrete and polyphenylene particles, which is applied in the direction of insulation, floor slabs, building components, etc., can solve the problems of on-site pouring of concrete for laminated slabs, achieve simple and efficient production procedures, good integrity, improve shear resistance and overall sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

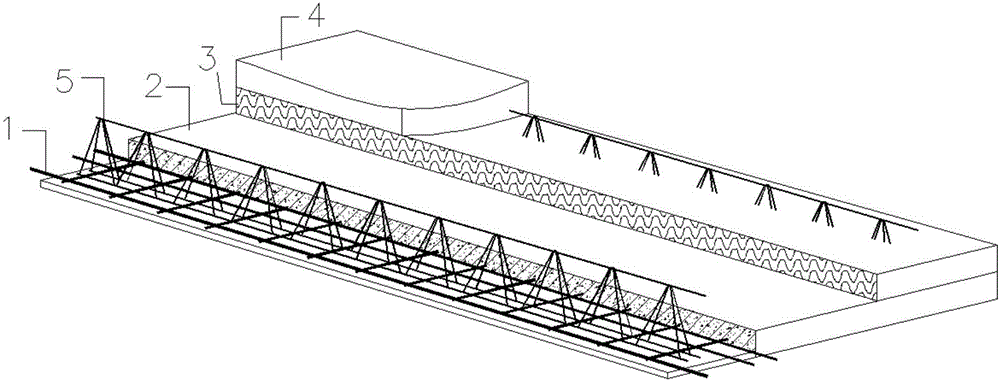

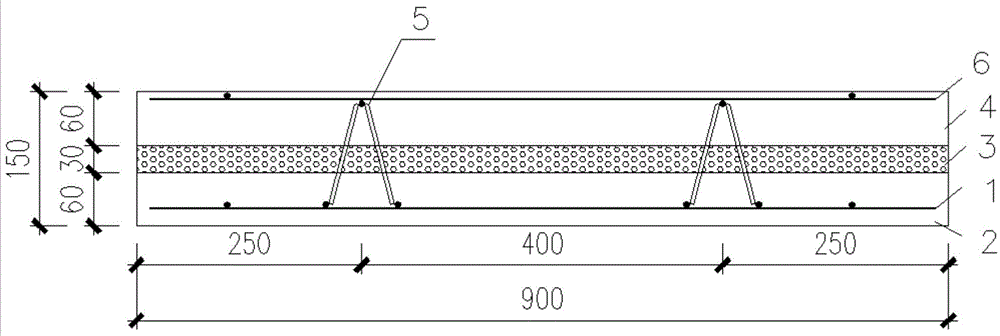

[0023] Such as figure 1 with figure 2 As shown, the laminated floor slab based on polyphenylene particle fiber concrete sandwich insulation in the present invention includes a prefabricated bottom slab concrete layer 2, and a prefabricated bottom slab insulation layer 3 of polyphenylene particle fiber concrete is arranged on the prefabricated bottom slab concrete layer 2. There is a post-cast layer 4 on the fiber concrete prefabricated floor insulation layer 3 . Among them, the prefabricated bottom slab concrete layer 2 has bottom slab steel bars 1 , and the post-cast layer 4 has post-cast layer structural steel bars 6 .

[0024] It can be seen that the laminated floor slab with sandwich insulation is composed of prefabricated concrete floor, prefabricated insulation layer and on-site post-cast layer, and the shear resistance mode of the join...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com