Galvanized and electrophoretic paint coated gas steel pipe and preparation method of galvanized and electrophoretic paint coated gas steel pipe

A technology of galvanized steel pipe and electrophoretic paint, applied in the direction of electrophoretic coating, pipe, rigid pipe, etc., can solve the problem that galvanized steel pipe cannot withstand acid and alkaline environment corrosion, and galvanized steel pipe is not very effective in rust prevention and ultraviolet resistance. Good, reduce the service life of gas pipelines, etc., to achieve the effect of improving rust and ultraviolet resistance, good acid and alkali resistance, broadening the scope of use and environmental adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

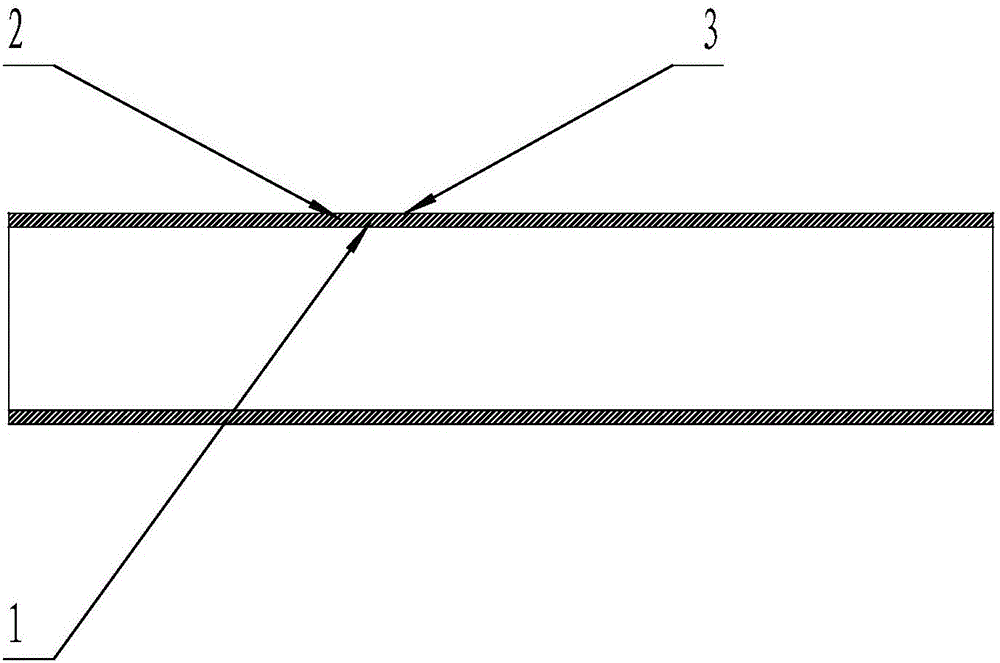

[0018] Such as figure 1 As shown, a galvanized electrophoretic paint steel pipe for gas, including a steel pipe substrate, is characterized in that: the surface of the steel pipe substrate has a galvanized layer and an electrophoretic paint layer in turn, the galvanized layer is the inner layer, and the electrophoretic paint is Outer layer: the thickness of the galvanized layer is 55 μm, the thickness of the electrophoretic paint layer is 30 um, adhesion ≤ grade 1, impact force ≥ 70kg.cm, pencil hardness ≥ H, UV resistance 400h, acid resistance 3 hours (6mol);

[0019] The electrophoretic paint layer is an acrylic epoxy resin paint layer.

[0020] A method for preparing a galvanized electrophoretic paint steel pipe for gas, characterized in that it comprises the following steps:

[0021] A. Galvanizing steps for the steel pipe substrate: when the steel pipe substrate is galvanized, the temperature of the galvanizing solution is 435°C, the galvanizing time is 45 seconds, the w...

Embodiment 2

[0027] Such as figure 1 As shown, a galvanized electrophoretic paint steel pipe for gas, including a steel pipe substrate, is characterized in that: the surface of the steel pipe substrate has a galvanized layer and an electrophoretic paint layer in turn, the galvanized layer is the inner layer, and the electrophoretic paint layer is Outer layer; the thickness of the galvanized layer is 60 μm, the thickness of the electrophoretic paint layer is 40 um, adhesion ≤ grade 1, impact force ≥ 70kg.cm, pencil hardness ≥ H, UV resistance 500h, acid resistance 4 hours (6mol);

[0028] The electrophoretic paint layer is an acrylic epoxy resin paint layer.

[0029] A method for preparing a galvanized electrophoretic paint steel pipe for gas, characterized in that it comprises the following steps:

[0030] A. Galvanizing steps for the steel pipe substrate: when the steel pipe substrate is galvanized, the temperature of the galvanizing solution is 455°C, the galvanizing time is 55 seconds,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com