Galvanized dip coating malleable cast iron pipe fitting and preparation method thereof

A technology of galvanized malleable steel pipe and malleable steel pipe, which is applied in the field of pipeline connectors and its preparation, can solve the problem that galvanized malleable steel pipe fittings cannot withstand acidic and alkaline environment corrosion, and the antirust effect of galvanized malleable steel pipe fittings is not very good. Protective paint material consumption and other issues, to achieve the effect of broadening the scope of use and environmental adaptability, good acid and alkali resistance protection performance, and increasing market share

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

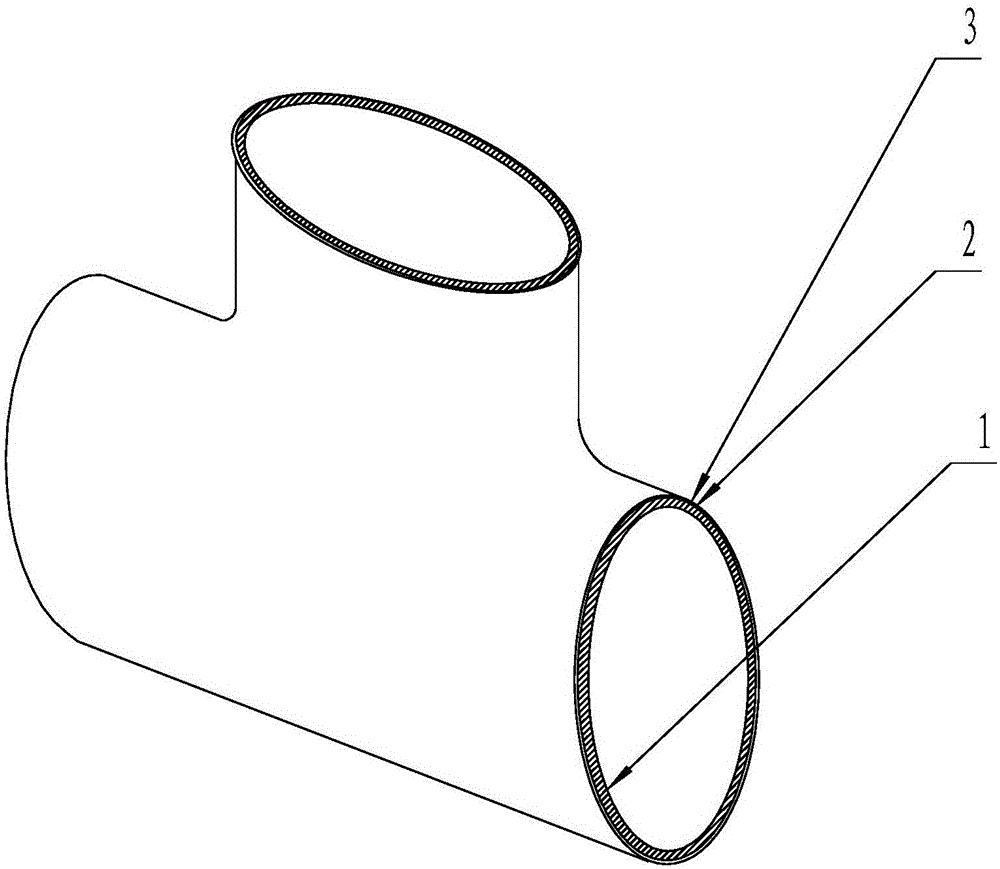

[0022] like figure 1 As shown, a galvanized and dipped malleable steel pipe fitting, comprising a malleable steel pipe fitting base 1, is characterized in that: the surface of the malleable steel pipe fitting base 1 has a galvanized layer 2 and a paint dipped layer 3 in sequence, and the galvanized layer 2 is an inner layer , the varnish layer 3 is the outer layer; the thickness of the galvanized layer 2 is 50 μm; the thickness of the varnish layer 3 is 40 um, the adhesion ≤ grade 1, and the impact ≥ 70 kg.cm.

[0023] A preparation method for galvanized and dipped malleable steel pipe fittings is characterized in that it comprises the following steps:

[0024] A. Steps of shot blasting of malleable steel pipe fitting substrate 1: the shot blasting time of malleable steel pipe fitting substrate 1 is 30 minutes, so that the surface of malleable steel pipe fitting substrate 1 meets the national standard, that is, the ASa3 grade in the corrosion grade and derusting grade of the s...

Embodiment 2

[0035] like figure 1 As shown, a galvanized and dipped malleable steel pipe fitting, comprising a malleable steel pipe fitting base 1, is characterized in that: the surface of the malleable steel pipe fitting base 1 has a galvanized layer 2 and a paint dipped layer 3 in sequence, and the galvanized layer 2 is an inner layer , the varnish layer 3 is the outer layer; the galvanized layer 2 has a thickness of 80 μm; the varnish layer 3 has a thickness of 70 um, adhesion ≤ grade 1, and impact ≥ 70 kg.cm.

[0036] A preparation method for galvanized and dipped malleable steel pipe fittings is characterized in that it comprises the following steps:

[0037] A. Steps of shot blasting of malleable steel pipe fitting substrate 1: the shot blasting time of malleable steel pipe fitting substrate 1 is 40 minutes, so that the surface of malleable steel pipe fitting substrate 1 meets the national standard, that is, the ASa3 grade in the corrosion grade and derusting grade of the steel surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com