Galvanized steel pipe inner wall blowing head

A technology for galvanized steel pipe and pipe inner wall, applied in the field of metallurgy, can solve the problems affecting the stable and uniform injection of zinc liquid, no published patent documents are found, and the injection is not very uniform, and the injection effect is good and the pressure is increased. , the effect of improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

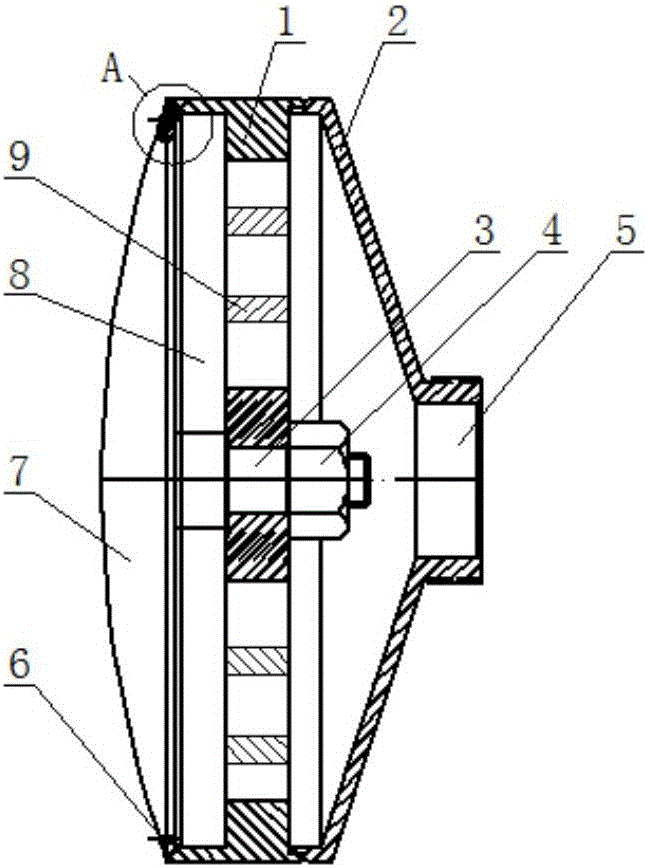

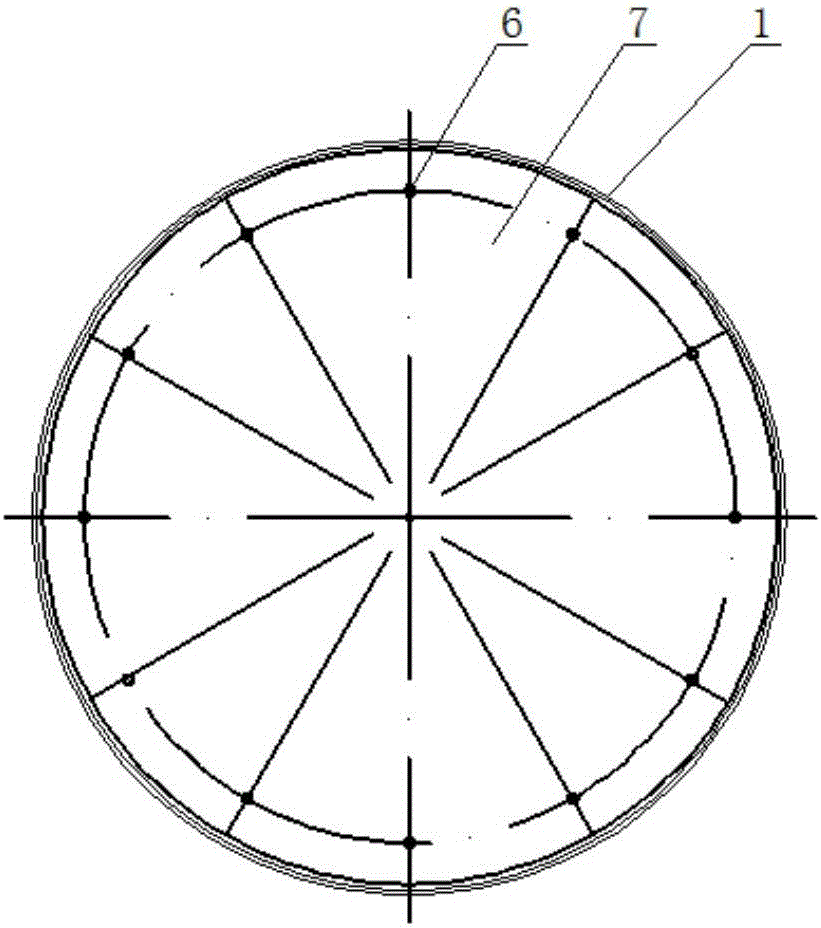

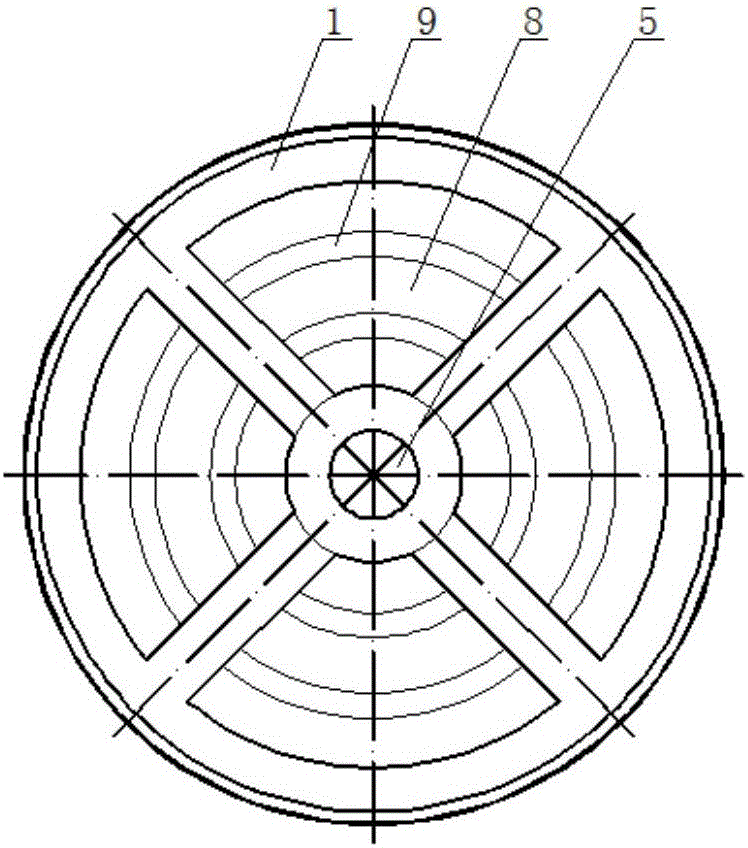

[0020] A blowing head for the inner wall of a galvanized steel pipe, including a gland 2, a cylinder body 1, and an air head 7. The head of the air head is in the shape of a sphere, and the bolt 3 made at the shaft part is coaxial with the cylinder body, and is fastened by The nut 4 is fixed, the gland is coaxially fixed on the cylinder body, the gland is shaped on the air inlet 5, and the air chamber 8 is formed in the airtight space formed by the gland, the cylinder body and the gas head, and the inner edge of the cylinder end and the There is a gap 10 between the sphere outer edges of the air head, which is the air blow hole, and the pressure air entering from the air inlet forms an umbrella-shaped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com