Method for preparing copper powder and ferrous sulfate by using solution leached through sludge containing copper wet method

A technology of ferrous sulfate and copper sludge, applied in the direction of ferric sulfate and the improvement of process efficiency, can solve the problems of difficult to realize resource utilization, low product added value, incomplete metal separation, etc., and reduce the discharge of process wastewater. , High utilization rate of resources and significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The copper-containing sludge comes from the sewage treatment plant of a printed circuit board enterprise in Hunan. The sludge containing Cu is obtained after microbial leaching. 2+ 12.4g / L, Fe 2+ 20.3g / L, Fe 3+ 21.6g / L, Al 3+ 0.8g / L, Cr 3+ 0.5g / L wet leaching solution, the pH value of the wet leaching solution is 2.0.

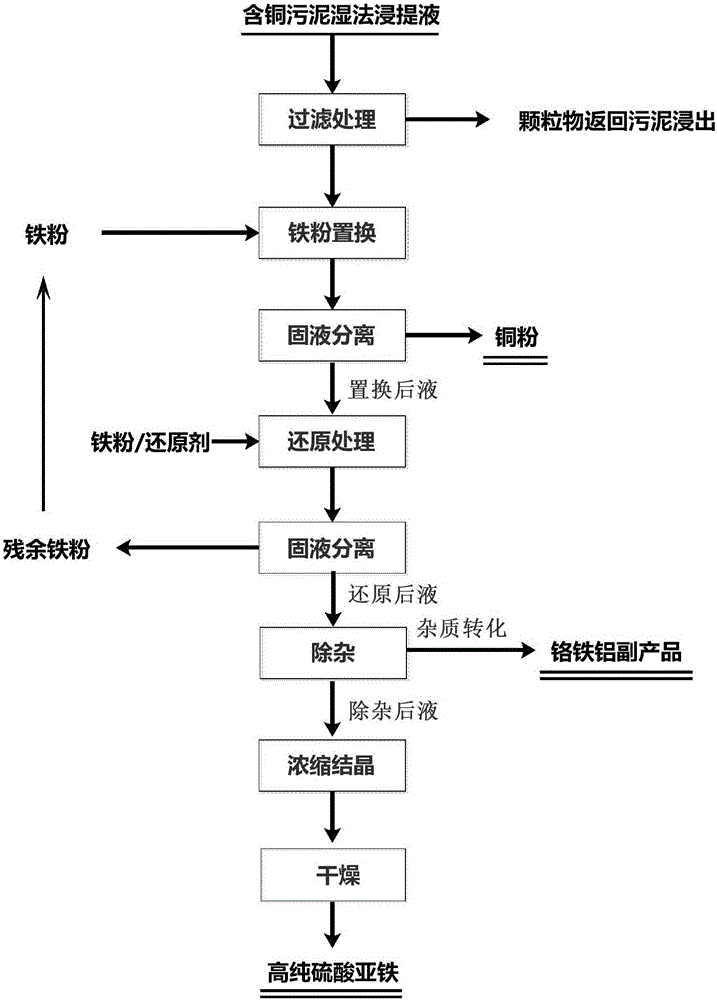

[0042] Such as figure 1 As shown, adopting the method of the present invention to utilize the above-mentioned copper-containing sludge wet leaching solution of the present embodiment to prepare copper powder and ferrous sulfate, specifically comprises the following steps:

[0043] ① Fine filtration of leachate: take 2L of copper-containing sludge wet leaching solution, first filter through fast filter paper to remove large suspended particles in the leaching process, and obtain leachate after fine filtration;

[0044] ② Iron powder replacement: transfer the finely filtered leaching solution to a 5L reaction vessel with a stirring device, control the...

Embodiment 2

[0053] The copper-containing sludge comes from a sewage treatment plant of a surface treatment company in Wuxi, and the sludge containing Cu is obtained after microbial leaching. 2+ 3.6g / L, Fe 2+ 24.3g / L, Fe 3+ 14.6g / L, Al 3+ 1.2g / L, Cr 3+ 1.4g / L wet leaching solution, pH 1.5.

[0054] Using the method of the present invention to prepare copper powder and ferrous sulfate using the copper-containing sludge wet leaching solution of the present embodiment above, specifically comprises the following steps:

[0055] ①Finish filtration of leachate: take 100L of copper-containing sludge wet leaching solution, first filter through -600 mesh filter cloth to remove large suspended particles in the leaching process, and obtain leachate after fine filtration;

[0056] ② Iron powder replacement: transfer the finely filtered leaching solution to a 200L reaction tank with a stirring device, control the stirring line speed of the reactor at 4m / s, add 470g of iron powder in an amount 1.5 t...

Embodiment 3

[0062] The copper-containing sludge comes from a sewage treatment plant in an electroplating park in Jiangsu. After the sludge is leached by microorganisms, the copper-containing sludge is obtained. 2+ 5.4g / L, Fe 2+ 18.7g / L, Fe 3+ 7.6g / L, Al 3+ 0.8g / L, Cr 3+ 0.01g / L wet leaching solution, pH value is 1.5.

[0063] Using the method of the present invention to prepare copper powder and ferrous sulfate using the copper-containing sludge wet leaching solution of the present embodiment above, specifically comprises the following steps:

[0064] ①Finish filtration of leachate: take 500L copper-containing sludge wet leaching solution, first filter through -600 mesh filter cloth to remove large suspended particles in the leaching process, and obtain leachate after fine filtration;

[0065] ② Iron powder replacement: transfer the leachate after fine filtration to 1m 3 In the reaction tank with stirring device, the linear speed of the stirring device should be controlled

[0066] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com