Method and application of hyssop extract in tobacco preparation

A technology of hyssop and extract is applied in the field of preparation of hyssop extract for tobacco, and achieves the effects of improving aroma texture, soft and delicate smoke, and improving smell stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

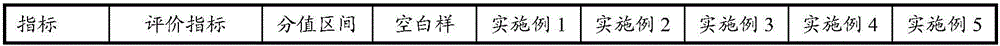

Examples

Embodiment 1

[0027] (1) Grind hyssop into powder and pass through a 40-mesh sieve, mix hyssop powder under the net, 30% alcohol solution by volume, and sodium chloride at a mass ratio of 1:10:0.05, and reflux for 2 hours Finally, to obtain the reflux extract, add 5% tartaric acid aqueous solution into the reflux extract by mass percentage, stir while adding, adjust the pH to 5, and filter with a 0.45 μm membrane, the obtained filtrate is the crude extract of hyssopus, and the filter residue abandoned.

[0028] (2) the hyssopus crude extract in step (1) is transferred in the material tank of molecular distillation equipment, at scraper speed 300r / min, vacuum tightness 150Pa, distillation temperature 40 ℃, feed rate 1ml / min, Molecular distillation was carried out under the condition of condensation temperature of 6°C to obtain light components and heavy components, and the light components were discarded.

[0029] (3) Add a butyl acetate solvent whose volume is 1 / 3 times its volume to the h...

Embodiment 2

[0032] (1) Grind hyssop into powder and pass through a 40-mesh sieve, mix hyssop powder under the net, 30% alcohol solution by volume, and sodium chloride at a mass ratio of 1:12:0.06, and reflux for 2 hours Finally, to obtain the reflux extract, add 5% tartaric acid aqueous solution into the reflux extract by mass percentage, stir while adding, adjust the pH to 5, and filter with a 0.45 μm membrane, the obtained filtrate is the crude extract of hyssopus, and the filter residue abandoned.

[0033] (2) the hyssopus crude extract in step (1) is transferred to the material tank of molecular distillation equipment, at scraper speed 350r / min, vacuum degree 200Pa, distillation temperature 35 ℃, feed rate 1ml / min, Molecular distillation was carried out under the condition of condensation temperature 5°C to obtain light components and heavy components, and the light components were discarded.

[0034] (3) Add butyl acetate whose volume is 1 / 2 times its volume to the heavy component f...

Embodiment 3

[0037] (1) Grind hyssop into powder and pass through a 40-mesh sieve, mix hyssop powder under the net, 35% alcohol solution by volume, and sodium chloride at a mass ratio of 1:12:0.05, and reflux for 3 hours Finally, to obtain the reflux extract, add 5% tartaric acid aqueous solution into the reflux extract by mass percentage, stir while adding, adjust the pH to 5.5, and filter with a 0.45 μm membrane, the obtained filtrate is the crude extract of hyssopus, and the filter residue abandoned.

[0038] (2) the hyssopus crude extract in step (1) is transferred in the material tank of molecular distillation equipment, at scraper rotating speed 400r / min, vacuum tightness 250Pa, distillation temperature 40 ℃, feed rate 3ml / min, Molecular distillation was carried out under the condition of condensation temperature of 10°C to obtain light components and heavy components, and the light components were discarded.

[0039] (3) Add ethyl butyrate extraction solvent whose volume is 1 / 2 tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com