Pressure-sensitive adhesive for reflection type high-durability polaroid and polaroid with pressure-sensitive adhesive applied

A polarizer, pressure-sensitive adhesive technology, applied in optics, optical components, polarizing components, etc., can solve the problems of affecting the use effect and poor perforation of the aluminum layer, and achieve the advantages of reducing corrosion, wide bonding range and good bonding performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

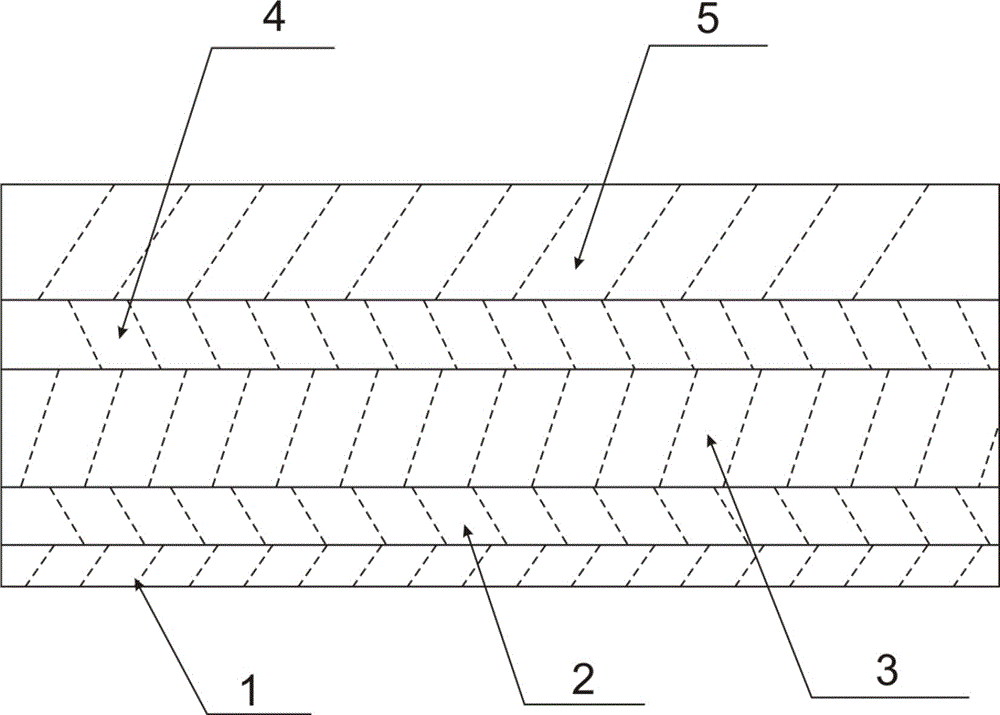

Image

Examples

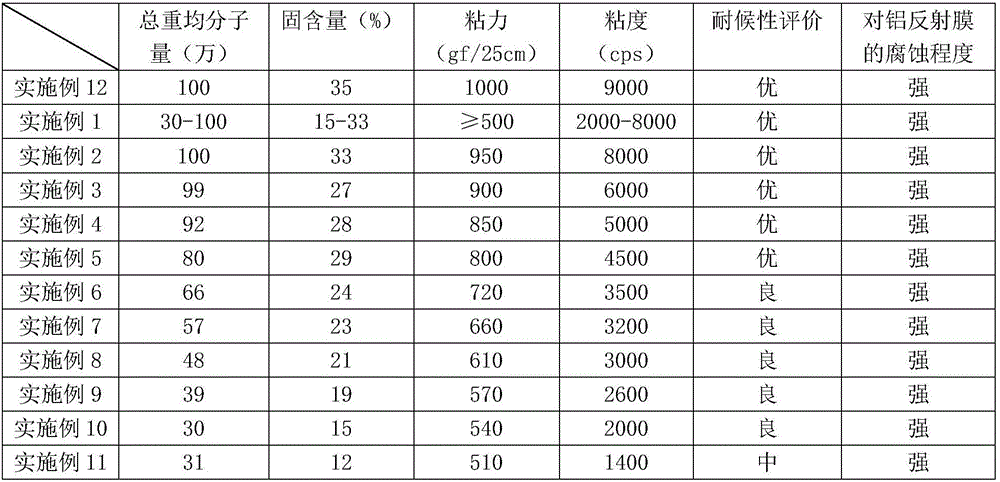

Embodiment 1

[0026] The weight percentage of acrylate polymer is 80%-85%, and the weight average molecular weight is 100000-900000; the weight percentage of hydroxyethyl acrylate polymer is 14.8%-19%, and the weight average molecular weight is 100000-200000; The weight percentage of the bridging agent is 0.2%-1.0%.

Embodiment 2

[0028]The weight percentage of acrylate polymer is 85%, and the weight average molecular weight is 900000; The weight percentage of hydroxyethyl acrylate polymer is 14.8%, and the weight average molecular weight is 100000; The weight percentage of polyisocyanate bridging agent is 0.2 %.

Embodiment 3

[0030] The weight percentage of acrylate polymer is 84%, and the weight average molecular weight is 860000; The weight percentage of hydroxyethyl acrylate polymer is 15.7%, and the weight average molecular weight is 130000; The weight percentage of polyisocyanate bridging agent is 0.3% .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com