Advanced treatment technology for wastewater

A treatment process and advanced treatment technology, which is applied in the direction of processing wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. It can solve the problems of large amount of chemicals used, high economic cost, and unstable effluent. , to save economic costs, increase reaction efficiency, and reduce the amount of chemicals used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

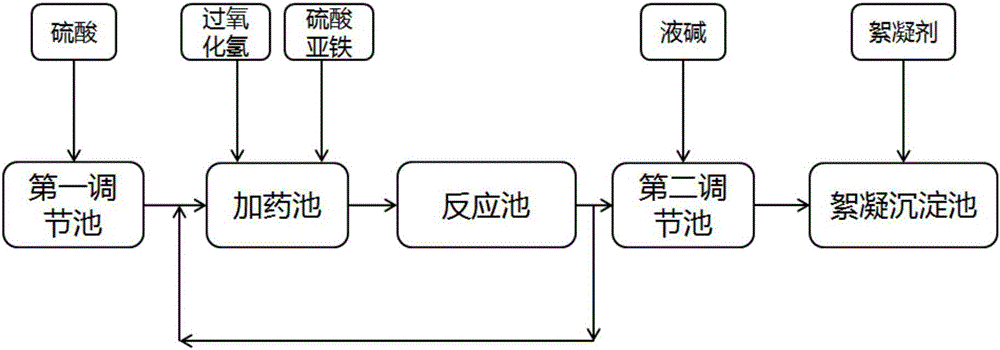

Method used

Image

Examples

Embodiment 4

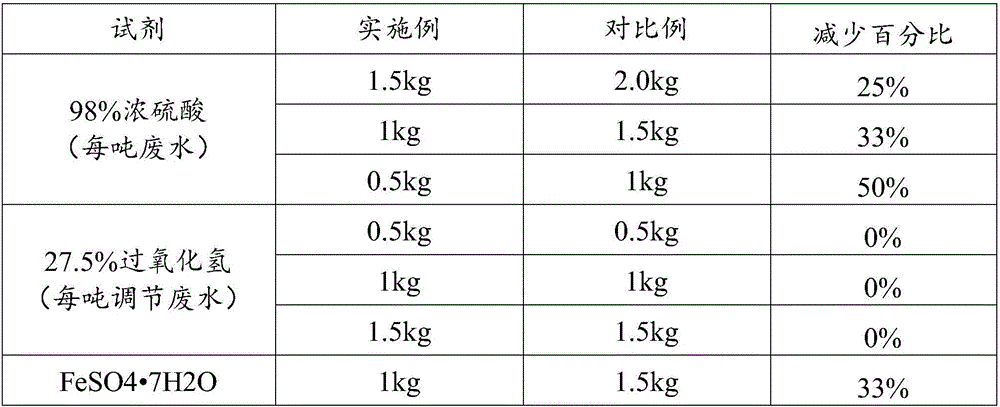

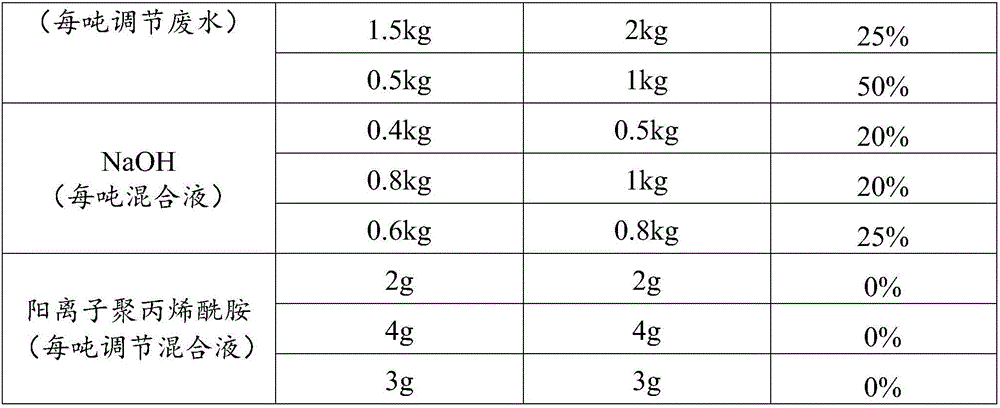

[0044] Embodiment 4 simulates the treatment of the above-mentioned wastewater by the advanced treatment process of the present invention through a small test, and Comparative Example 4 simulates the treatment of the wastewater by the traditional Fenton process through a small test. In Example 4 and Comparative Example 4, the dosages of hydrogen peroxide and ferrous sulfate were the same, and the COD of the final effluent was investigated.

[0045]Those skilled in the art should understand that the treatment process of the biochemical effluent of a certain corrugated paper factory in the present invention is only illustrative, and the advanced treatment process of the present invention can be applied to the treatment of any other type of wastewater.

Embodiment 1

[0047] According to the following steps, the above-mentioned waste water is treated:

[0048] (1) Add 98% concentrated sulfuric acid to the first adjustment tank to adjust the pH of the wastewater to 4-5 to obtain regulated wastewater, wherein 1.5 kg of concentrated sulfuric acid is added per ton of wastewater.

[0049] (2) the regulated waste water is delivered to two mutually independent units of the dosing pool, and to these two units, adding the concentration of 27.5% hydrogen peroxide solution and the concentration of 15% ferrous sulfate solution respectively, so that The hydrogen peroxide solution and the ferrous sulfate solution are respectively mixed with the waste water to obtain the first waste water and the second waste water. Among them, the amount of hydrogen peroxide used in each ton of regulated wastewater is 0.5kg, pure FeSO 4 ·7H 2 The amount of O used was 1 kg.

[0050] (3) Contact and react the first waste water and the second waste water in the reaction ...

Embodiment 2

[0054] According to the following steps, the above-mentioned waste water is treated:

[0055] (1) Add 98% concentrated sulfuric acid in the first adjustment tank, adjust the pH of the above wastewater to 4-5, and obtain adjusted wastewater, wherein 1 kg of concentrated sulfuric acid is added to each ton of wastewater.

[0056] (2) the regulated waste water is delivered to two mutually independent units of the dosing pool, and to these two units, adding the concentration of 27.5% hydrogen peroxide solution and the concentration of 15% ferrous sulfate solution respectively, so that The hydrogen peroxide solution and the ferrous sulfate solution are respectively mixed with the waste water to obtain the first waste water and the second waste water. Among them, the amount used in each ton of regulated wastewater is 1kg, pure FeSO 4 ·7H 2 The amount of O used was 1.5 kg.

[0057] (3) Contact the first wastewater and the second wastewater in the reaction tank and react for 1 hour ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com