Technology for preparing boehmite microcrystal powder only through adjusting pressure

A technology for adjusting pressure and boehmite, applied in inorganic chemistry, chemical instruments and methods, aluminum compounds, etc., can solve problems such as corrosion of equipment, unsuitability for industrial mass production, complicated operation, etc., to avoid pollution and shorten the reaction cycle , The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

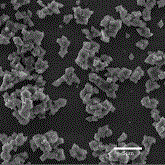

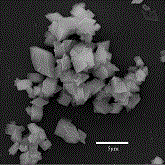

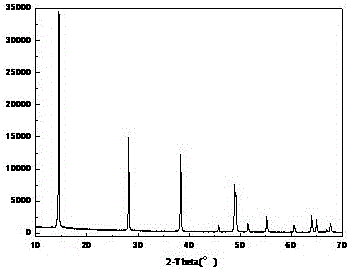

Image

Examples

Embodiment 1

[0020] 2.0kg alumina trihydrate powder (D 50 =13μm) and 4.0L of distilled water were added to a high-pressure hydrothermal kettle, stirred at a speed of 600rpm while heating, the temperature was raised to a pressure of 1.2MPa, and the pressure was maintained for 1.5h to obtain a boehmite slurry, which was taken out and cooled to room temperature naturally. Then use distilled water to filter and wash repeatedly until the filtrate pH=7, and finally dry the filtered product at 120°C for 12 hours to prepare the required boehmite microcrystalline powder. The boehmite microcrystal powder prepared in this example Granite size D 50 =3.42μm.

Embodiment 2

[0022] 2.0kg alumina trihydrate powder (D 50 =13μm) and 4.0L of distilled water were added to a high-pressure hydrothermal kettle, stirred at a speed of 600rpm while heating, the temperature was raised to a pressure of 1.4MPa, and the pressure was maintained for 1.5h to obtain a boehmite slurry, which was taken out and cooled to room temperature naturally. Then use distilled water to filter and wash repeatedly until the filtrate pH=7, and finally dry the filtered product at 120°C for 12 hours to prepare the required boehmite microcrystalline powder. The boehmite microcrystal powder prepared in this example Granite size D 50 =3.11 μm.

Embodiment 3

[0024] 2.0kg alumina trihydrate powder (D 50 =13μm) and 4.0L of distilled water were added to a high-pressure hydrothermal kettle, stirred at a speed of 600rpm while heating, the temperature was raised to a pressure of 1.6MPa, and the pressure was maintained for 1.5h to obtain a boehmite slurry, and the slurry was taken out and naturally cooled to room temperature, and then Repeated suction filtration and washing with distilled water until the filtrate pH = 7, and finally dried the product after suction filtration at 120°C for 12 hours to prepare the required boehmite microcrystal powder, the boehmite microcrystal powder prepared in this example Stone microcrystalline powder particle size D 50 =2.97μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com