Automobile decoupling distributed brake system electric-hydraulic combined braking execution mechanism

A technology of braking system and actuator, applied in the direction of brake transmission, brake, cooling brake, etc., can solve the problem of insufficient use of braking energy, etc., to improve braking performance and safety performance, good work reliability and Anti-failure ability, the effect of improving thermal decay resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

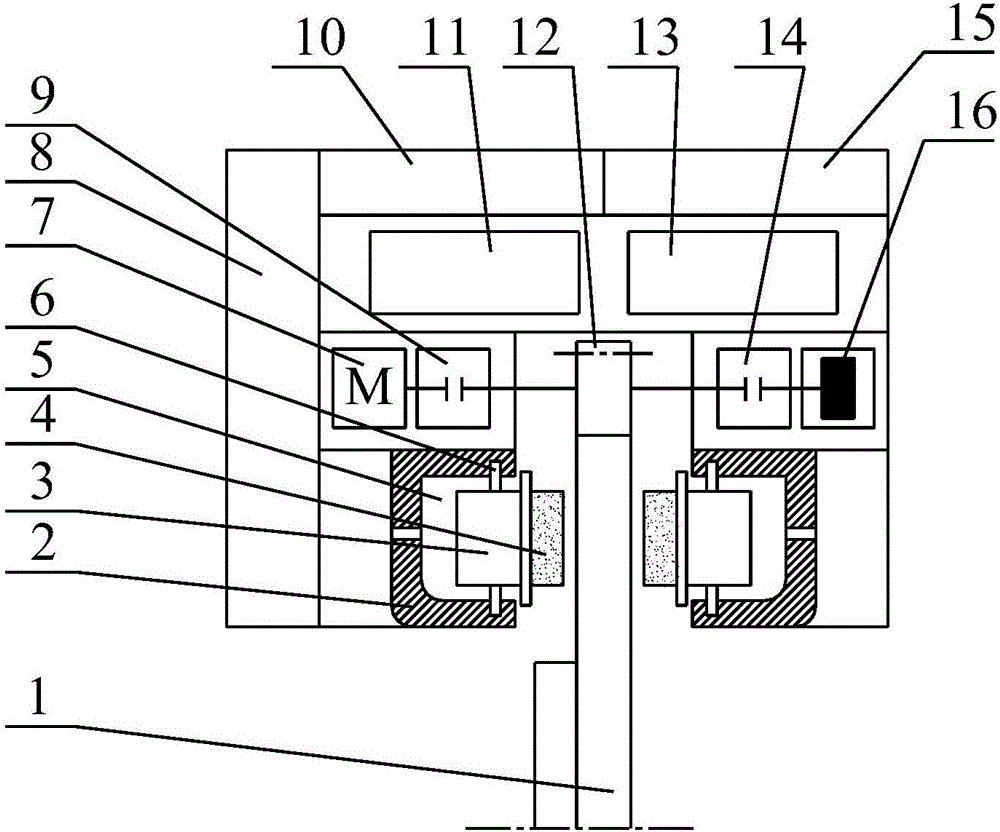

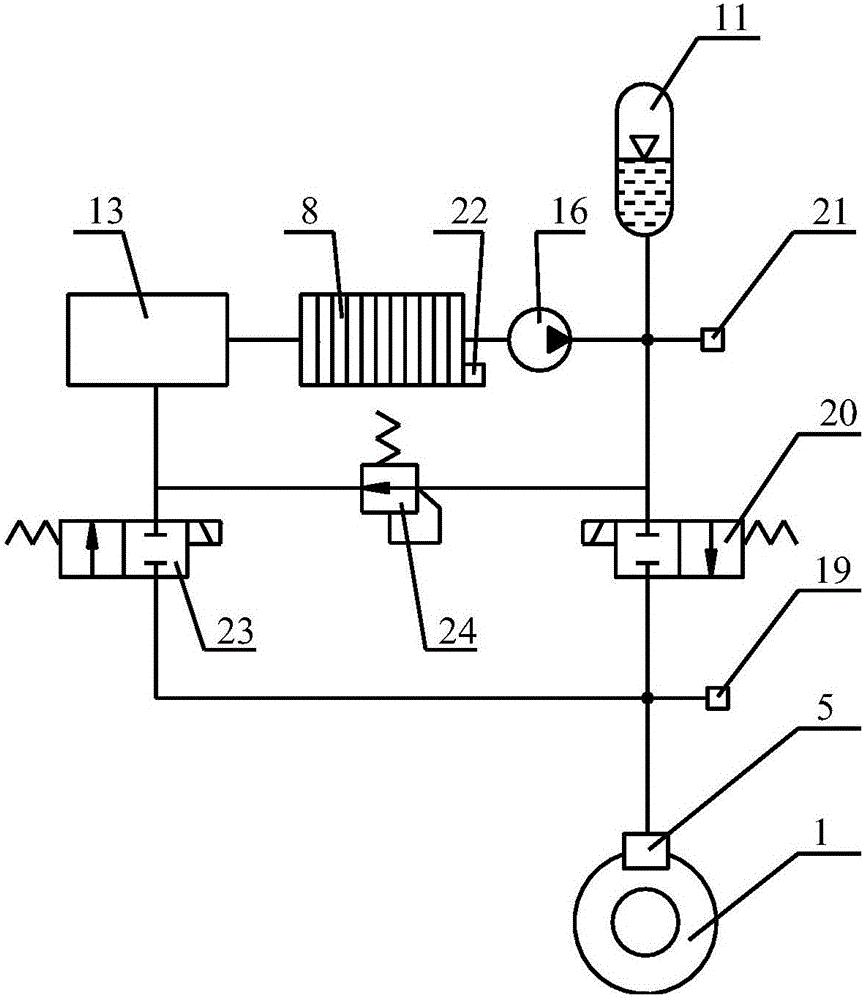

[0028] Such as figure 1 As shown, an electro-hydraulic composite brake actuator of an automobile decoupling distributed braking system includes a brake drive part 26 and a hydraulic brake actuator part 25. In order to save installation space, the brake drive part 26 in this embodiment Set inside the hydraulic brake execution part 25, the brake drive part 26 includes a brake disc 1, an oil pump clutch 14, a motor clutch 9, a battery pack 10 and an electronic control unit 15, the active part of the oil pump clutch 14 and The active parts of the motor clutch 9 are all in transmission connection with the brake disc 1. Specifically, the outer ring of the brake disc 1 is provided with a ring gear, and the pinion 12 meshes with the ring gear, so that the brake disc 1 is connected to the motor through the pinion 12. The clutch 9 and the oil pump clutch 14 are in transmission connection; the driven part of the oil pump clutch 14 is in transmission connection with the rotor of the oil p...

Embodiment 2

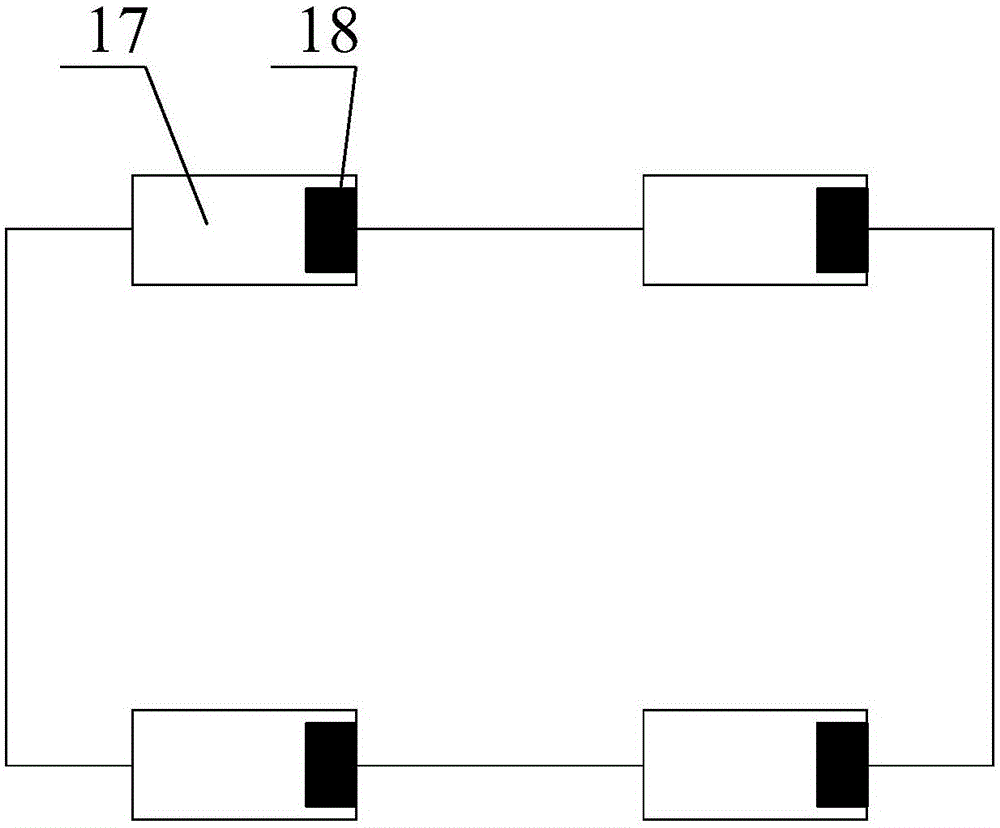

[0036] The difference from Example 1 is that, as Figure 4~6 As shown, the brake drive part 26 is arranged side by side with the hydraulic brake actuator part 25, and the two parts are integrated. Its working principle is the same as that in Embodiment 1. Compared with the arrangement in Embodiment 1, the arrangement in this embodiment can effectively reduce the overall height of the brake actuating structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com