Reinforced waterproof roll

A waterproof membrane and enhanced technology, which is applied in the direction of building insulation materials, building components, pavement details, etc., can solve the problems of affecting the waterproof performance of waterproof membranes, broken membranes, poor compression resistance and deformation resistance, etc., to achieve The effect of tight structure, improved strength and strong tensile capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

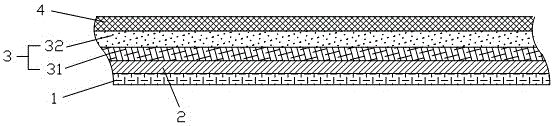

[0017] The embodiment of the present invention provides an enhanced waterproof coiled material, see figure 1 , The reinforced waterproof coiled material includes an isolation layer 1, a copper-aluminum-based waterproof layer 2, a reinforced layer 3, and an EPDM rubber layer 4 stacked in sequence;

[0018] Specifically, the isolation layer 1 is a polyethylene film or a polyester film;

[0019] Specifically, the copper-aluminum-based waterproof layer 2 is adhered to the side of the isolation layer 1;

[0020] Specifically, the reinforcement layer 3 is adhered to one side of the copper-aluminum-based waterproof layer 2, and the reinforcement layer 3 includes a fiber mesh cloth reinforcement layer 31 and a glass fiber layer 32 that are sequentially stacked;

[0021] Specifically, the upper and lower surfaces of the fiber mesh cloth reinforcement layer 31 are provided with protruding grid-like convex lines (not shown); the fiber mesh cloth reinforcement layer 31 is a polyester mesh cloth o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com