Control method of electric pulse spark discharge gap

A technology of spark discharge and control method, applied in circuits, manufacturing tools, electric processing equipment, etc., can solve problems such as affecting processing efficiency and processing quality, and inconvenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiment of the present invention will now be described in conjunction with the accompanying drawings.

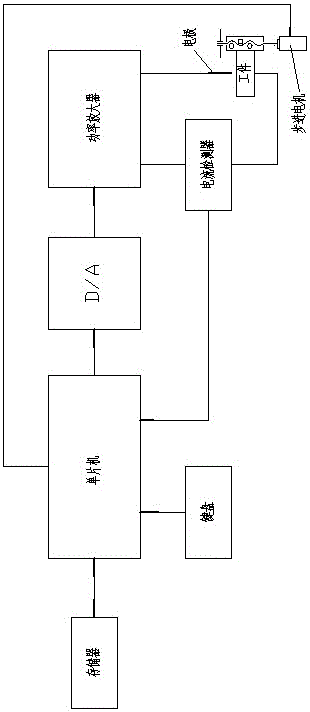

[0019] A control method for an electric spark pulse power supply device, the electric spark pulse power supply device includes a pulse signal generator composed of a single-chip microcomputer and a D / A converter, a power amplifier for power amplifying the pulse signal, and a power amplifier for detecting the power of the power amplifier. A current detector for output current, a memory for storing pulse signal information and output current information, and a keyboard for inputting data; its control method is realized by running the internal program of the single-chip microcomputer.

[0020] After starting up, the workpiece on the EDM machine moves to the electrode or the electrode moves to the workpiece at a certain speed;

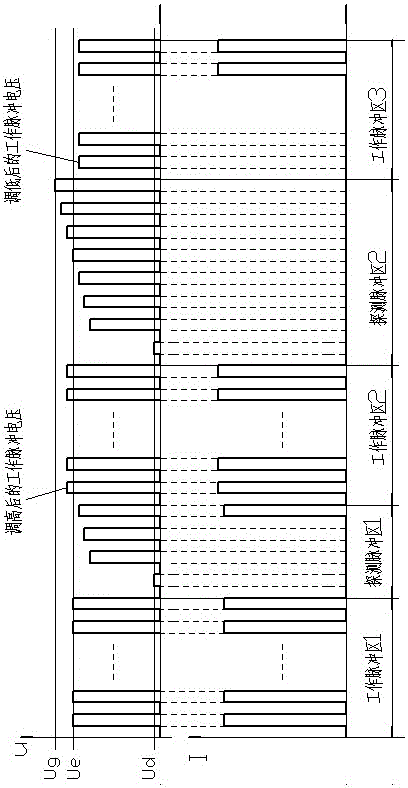

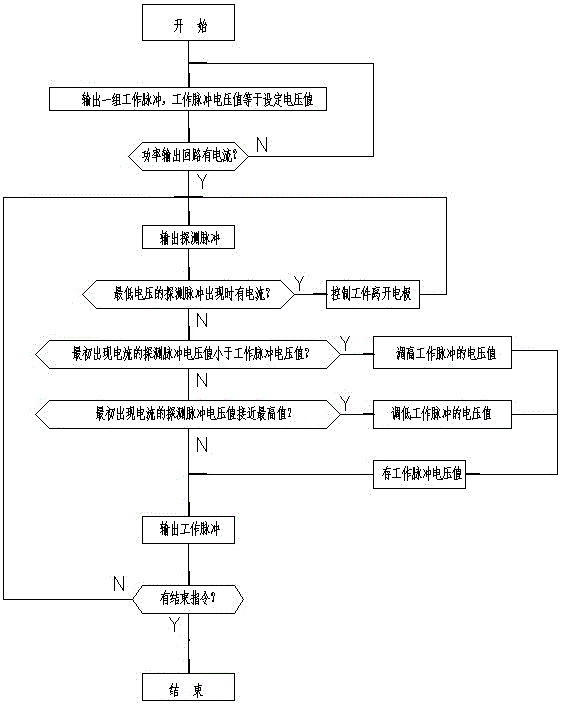

[0021] Run the internal program of the single chip microcomputer (the program flow chart is as follows image 3 Shown), the prog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com