Continuous production line technology process of steel wire aluminum

A technology of process flow and production line, which is applied in the field of continuous production line process of steel wire and aluminum, and can solve problems such as uneven distribution of iron, influence of molten steel quality, unstable aluminum yield, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

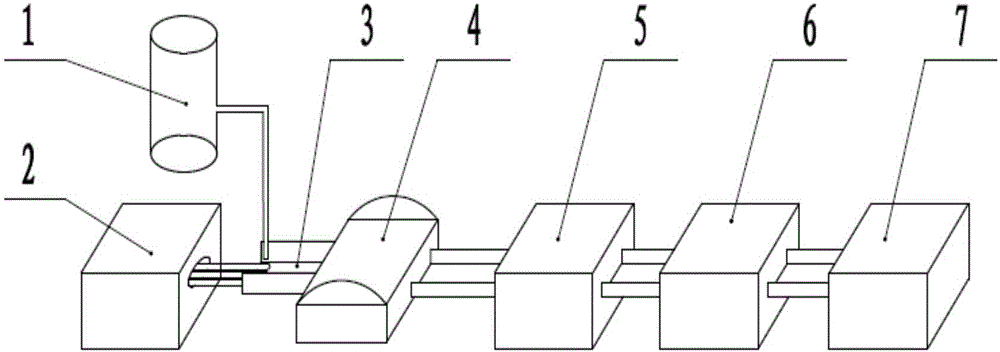

[0022] A continuous production line process for steel wire aluminum includes an aluminum melting furnace 1, a steel wire feeding device 2, a pouring device 4, a cooler 5, a tensioning and straightening transmission device 6 and a shearing device 7. The pouring device 4 is provided with pouring Nozzle 3, the aluminum melting furnace 1, the steel wire feeding device 2 are all connected to the pouring nozzle 3 of the pouring device 4, the pouring device 4, the cooler 5, the tensioning and straightening transmission device 6 and the shearing device 7 are connected in sequence ;

[0023] The specific steps for producing steel wire aluminum products are:

[0024] According to the content of aluminum in the steel wire aluminum, the corresponding number of steel wires are put into the steel wire feeding device 2, and the steel wire feeding device 2 passes the steel wire into the pouring nozzle 3 on the pouring device 4;

[0025] Put the aluminum ingot into the aluminum melting furnace 1 and...

Embodiment 2

[0032] A continuous production line process for steel wire aluminum includes an aluminum melting furnace 1, a steel wire feeding device 2, a pouring device 4, a cooler 5, a tensioning and straightening transmission device 6 and a shearing device 7. The pouring device 4 is provided with pouring Nozzle 3, the aluminum melting furnace 1, the steel wire feeding device 2 are all connected to the pouring nozzle 3 of the pouring device 4, the pouring device 4, the cooler 5, the tensioning and straightening transmission device 6 and the shearing device 7 are connected in sequence ;

[0033] The specific steps for producing steel wire aluminum products are:

[0034] According to the content of aluminum in the steel wire aluminum, the corresponding number of steel wires are put into the steel wire feeding device 2, and the steel wire feeding device 2 passes the steel wire into the pouring nozzle 3 on the pouring device 4;

[0035] Put the aluminum ingot into the aluminum melting furnace 1 and...

Embodiment 3

[0042] A continuous production line process for steel wire aluminum includes an aluminum melting furnace 1, a steel wire feeding device 2, a pouring device 4, a cooler 5, a tensioning and straightening transmission device 6 and a shearing device 7. The pouring device 4 is provided with pouring Nozzle 3, the aluminum melting furnace 1, the steel wire feeding device 2 are all connected to the pouring nozzle 3 of the pouring device 4, the pouring device 4, the cooler 5, the tensioning and straightening transmission device 6 and the shearing device 7 are connected in sequence ;

[0043] The specific steps for producing steel wire aluminum products are:

[0044] According to the content of aluminum in the steel wire aluminum, the corresponding number of steel wires are put into the steel wire feeding device 2, and the steel wire feeding device 2 passes the steel wire into the pouring nozzle 3 on the pouring device 4;

[0045] Put the aluminum ingot into the aluminum melting furnace 1 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com