Wear-resistant, hydrophobic and lipophilic material, preparation method therefor and application of wear-resistant, hydrophobic and lipophilic material

A hydrophobic, lipophilic and lipophilic technology, applied in separation methods, chemical instruments and methods, liquid separation, etc., can solve the problems of low purity of oil phase and water phase, affecting application, long preparation time, etc. The effect of large-scale production, good industrial development prospects, good environmental stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] In this embodiment, the base material is carbon fiber cloth.

[0038] Using the base material to prepare super-hydrophobic and super-oleophilic materials specifically includes the following steps:

[0039] Step 1: Soak the carbon fiber cloth in acetone to remove oil and impurities, then clean the residual solution and acetone on the surface of the carbon fiber cloth with ethanol solution, and finally clean it with deionized water. The cleaning is performed in ultrasonic. Then put it in an oven and dry it at 80-100°C for later use.

[0040] Step 2: Dissolve 1 g of copper acetate and 2.8 g of stearic acid in 100 ml of absolute ethanol, and stir at a constant speed for 10 min on a magnetic stirrer to obtain a metal stearate suspension;

[0041] 1g of low surface energy polydimethylsiloxane and 0.1g of curing agent were mixed and dissolved in 100ml of ethyl acetate to obtain a curing agent solution;

[0042] The stearic acid metal salt suspension is mixed with the curing ...

Embodiment 2

[0050] In this embodiment, the base material is completely the same as that in Embodiment 1.

[0051] The base material is used to prepare super-hydrophobic and super-oleophilic materials. The preparation method is basically the same as that in Example 1, except that in step 2, 0.2g of low surface energy polydimethylsiloxane and 0.02g The curing agent was mixed and dissolved in 100ml of ethyl acetate to obtain a curing agent solution.

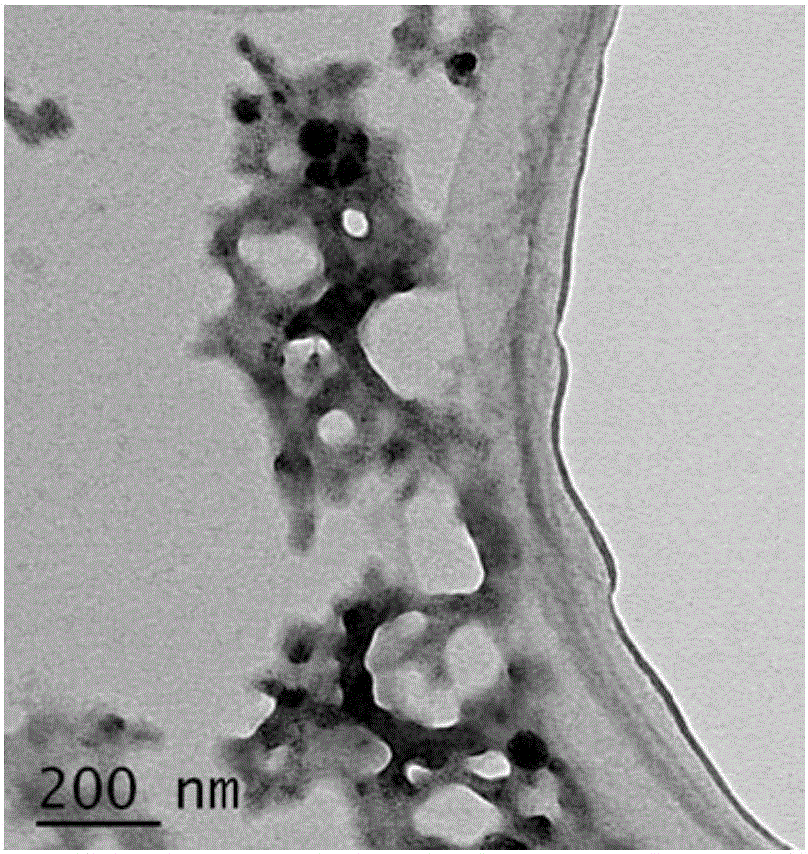

[0052] The scanning electron topography of the surface of the fiber cloth film coating made above is similar to figure 1 As shown, PDMS and stearate were shown to adhere to the substrate surface after drying.

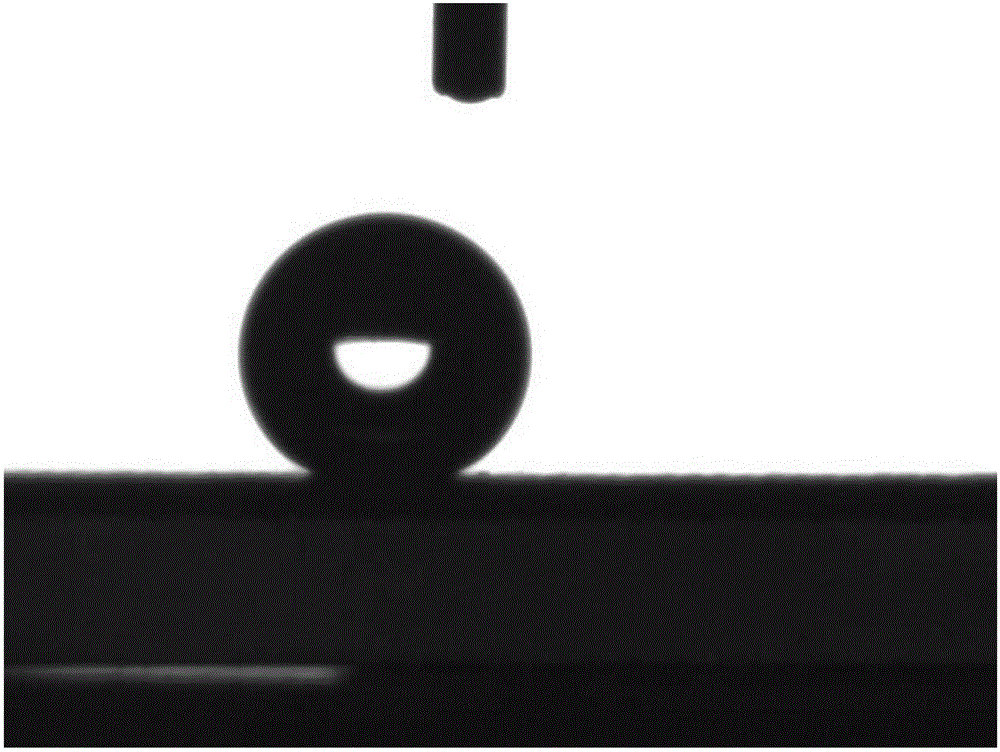

[0053] The apparent contact angle of the fiber cloth membrane prepared above to water and oil was tested, and the specific test method was exactly the same as that in Example 1. The measured results are that the contact angle of the sample to water is 136.23°, and the contact angle to oil is 0°.

Embodiment 3

[0055] In this embodiment, the base material is completely the same as that in Embodiment 1.

[0056] The base material is used to prepare superhydrophobic and superoleophilic materials. The preparation method is basically the same as that in Example 1, except that in step 2, 0.6g of low surface energy polydimethylsiloxane and 0.06g of The curing agent was mixed and dissolved in 100ml of ethyl acetate to obtain a curing agent solution.

[0057] The scanning electron topography of the surface of the fiber cloth film coating made above is similar to figure 1 As shown, PDMS and stearate were shown to adhere to the substrate surface after drying.

[0058] The apparent contact angle of the fiber cloth film coating prepared above to water and oil was tested, and the specific test method was exactly the same as that in Example 1. The measured results are that the contact angle of the sample to water is 147.62°, and the contact angle to oil is 0°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com