A double-pipe shield tail grouting device

A grouting device and tubular technology, applied in the field of shield tunneling machines, can solve the problems of blockage of solidified substances, many impurities, and easy blockage of grouting pipes, and achieve the effects of strong anti-blocking ability, overcoming easy falling off, and avoiding slurry backflow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

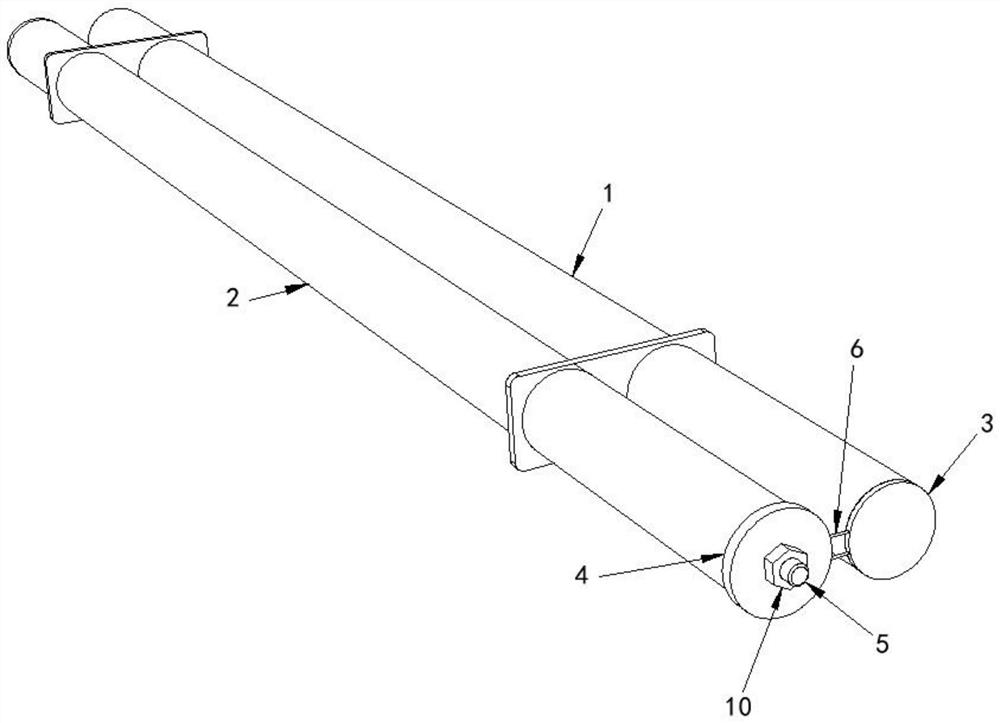

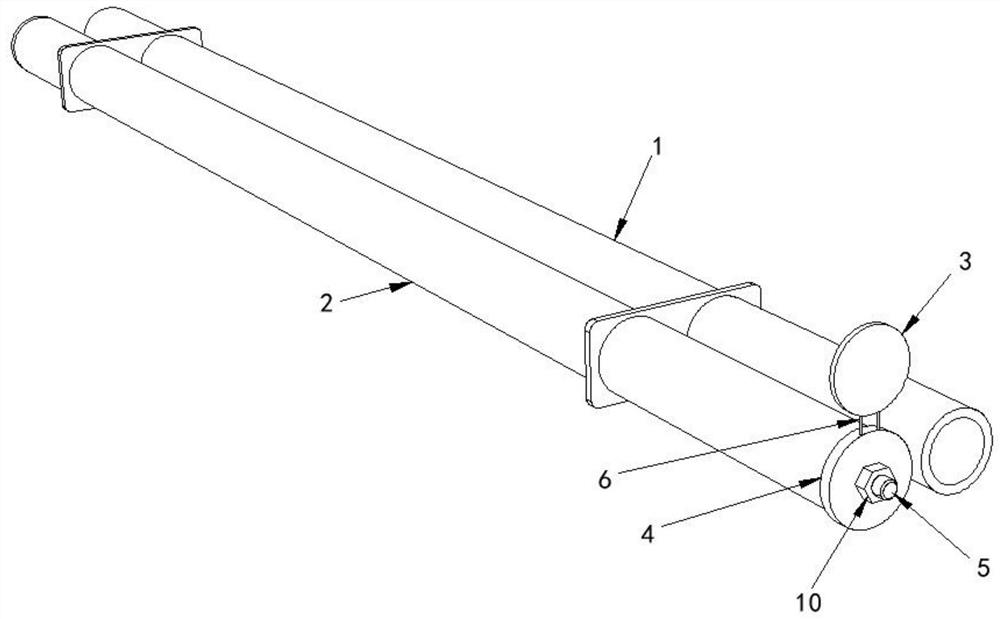

[0028] Such as Figure 1 to Figure 6 As shown, the double-tube shield tail grouting device in this embodiment includes a main pipe 1, a secondary pipe 2, a main end cover 3, an auxiliary end cover 4, a long rod 5 and a connecting rod 6;

[0029] The main pipe 1 and the auxiliary pipe 2 are parallel, and the main pipe 1 and the auxiliary pipe 2 are both cylindrical hollow pipes;

[0030] Such as Figure 4 As shown, the long rod 5 is located in the secondary pipe 2 and coaxial with the secondary pipe 2, the first end 501 of the long rod 5 exceeds the head of the secondary pipe 2, the first end 501 of the long rod 5 is provided with threads, and the long rod 5 is threaded. The first end 501 of the rod 5 is covered with a gasket 7 and a nut 8, and the diameter of the gasket 7 is not smaller than the outer diameter of the secondary pipe 2; the first end 501 of the long rod 5 is provided with a radial through hole 504;

[0031] The second end 502 of the long rod 5 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com