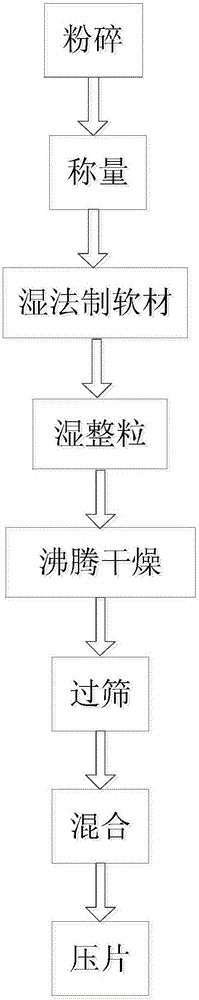

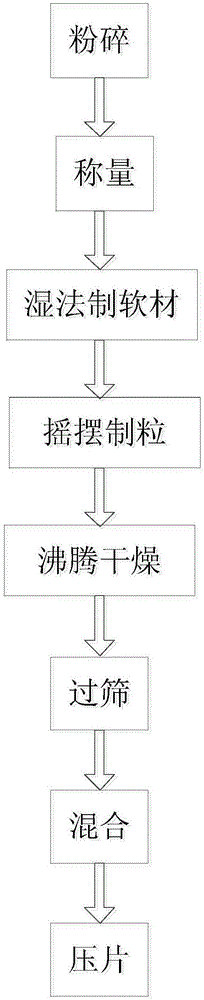

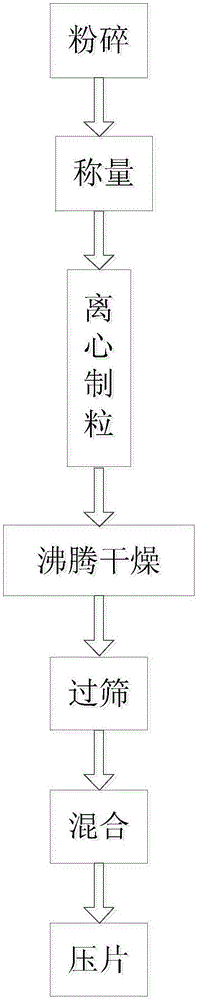

Preparation method of corn peptide tablets

A corn peptide and peptide flake technology, applied in the field of food processing, can solve the problems of unsatisfactory particle size distribution, unstable product quality, poor compressibility, etc., achieve ideal particle size distribution, shorten liquid spraying time, and eliminate potential safety hazards. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] A preparation method of corn peptide sheet, comprising the steps of:

[0078] The pulverization step is to pulverize corn oligopeptide powder, taurine, L-alanine, brown rice germ powder, povidone K30, dextrin, microcrystalline cellulose and hydroxypropyl methylcellulose to obtain raw material granules , wherein corn oligopeptide powder, taurine, L-alanine, brown rice germ powder and povidone K30 are crushed and passed through an 80-mesh sieve.

[0079] In the boiling granulation drying step, the weighed raw material particles are put into the hopper of the boiling granulator in turn, and the air is blown for preliminary mixing to bring it to a boiling state, and then water is used as a binder, and every 9kg of boiling mixture Spray 1L of atomized water, and spray the atomized water on the boiling mixture from the middle hole of the hopper of the boiling granulator to make it bonded into granules. After the mixture is bonded into granules, Stop spraying the atomized wat...

Embodiment 2

[0082] A preparation method of corn peptide sheet, comprising the steps of:

[0083] The pulverization step is to pulverize corn oligopeptide powder, taurine, L-alanine, brown rice germ powder, povidone K30, dextrin, microcrystalline cellulose and hydroxypropyl methylcellulose to obtain raw material granules , wherein corn oligopeptide powder, taurine, L-alanine, brown rice germ powder and povidone K30 are crushed and passed through an 80-mesh sieve.

[0084] In the boiling granulation drying step, the weighed raw material particles are put into the hopper of the boiling granulator in turn, and the air is blown for preliminary mixing to bring it to a boiling state, and then water is used as a binder, and every 9kg of boiling mixture Spray 1L of atomized water, spray the atomized water on the boiling mixture from the upper hole of the hopper of the boiling granulator, make it bonded into granules, after the mixture is bonded into granules, Stop spraying the atomized water, con...

Embodiment 3

[0087] A preparation method of corn peptide sheet, comprising the steps of:

[0088] The pulverization step is to pulverize corn oligopeptide powder, taurine, L-alanine, brown rice germ powder, povidone K30, dextrin, microcrystalline cellulose and hydroxypropyl methylcellulose to obtain raw material granules , wherein corn oligopeptide powder, taurine, L-alanine, brown rice germ powder and povidone K30 are crushed and passed through an 80-mesh sieve.

[0089] In the boiling granulation drying step, the weighed raw material particles are put into the hopper of the boiling granulator in turn, and the air is blown for preliminary mixing to bring it to a boiling state, and then water is used as a binder, and every 9kg of boiling mixture Spray 1L of atomized water, spray the water after atomization on the boiling mixture from the lower hole of the hopper of the boiling granulator, make it bonded into granules, after the mixture is bonded into granules, Stop spraying the atomized w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com