Anthraquinone molecule-cografted carbon/conductive polymer composite material and preparation method thereof

A technology of conductive polymers and anthraquinone molecules, applied in the direction of hybrid capacitor electrodes, etc., to achieve good application prospects, good cycle stability, and the effect of maintaining cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

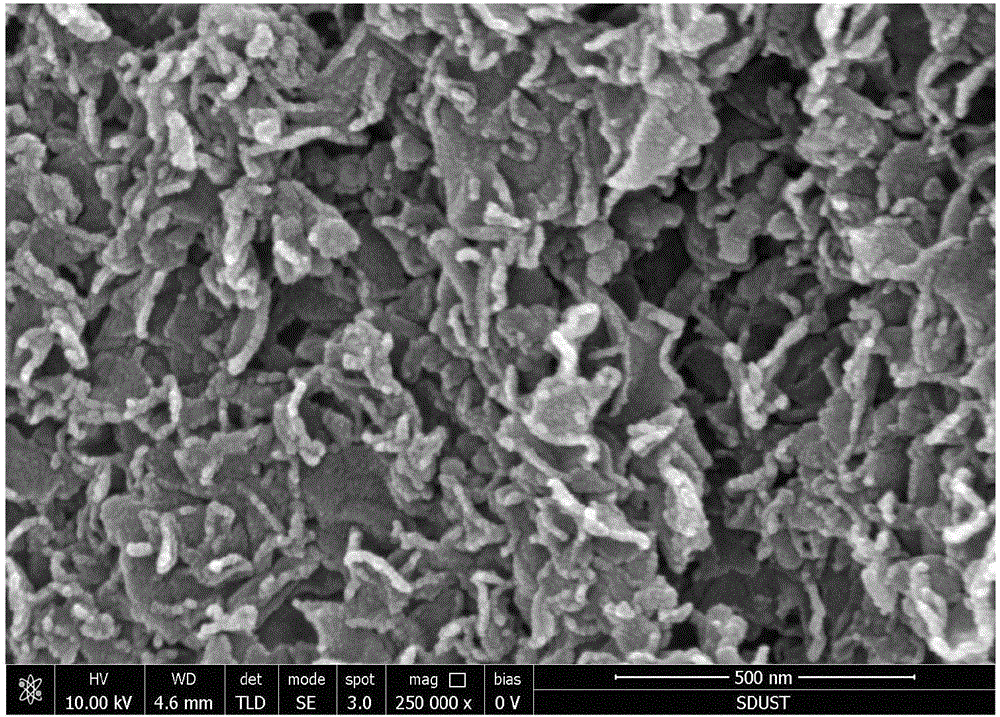

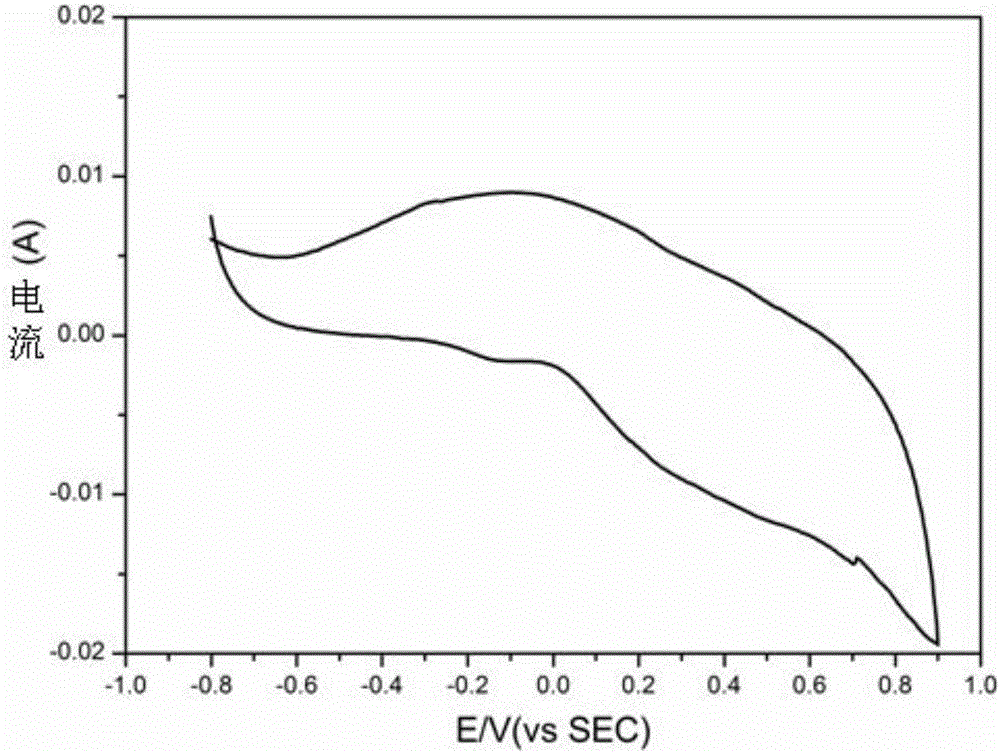

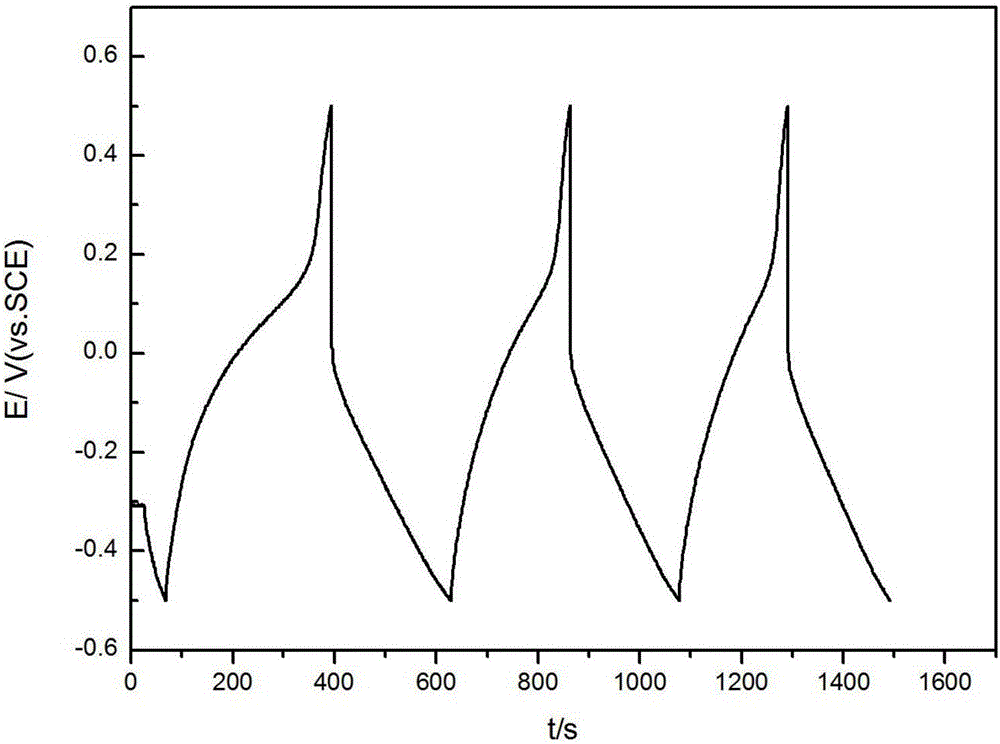

Image

Examples

Embodiment 1

[0032] A preparation method of anthraquinone molecule co-grafted carbon / conductive polymer composite material, characterized in that the steps are as follows:

[0033] (1) Add 1g of 1,4-diaminoanthraquinone (purchased from Shanghai Future Industry Co., Ltd.) into 100mL (10g / L) of ethanol, dissolve to form a solution, and set aside;

[0034] (2) Refer to Ogrin, D., Chattopadhyay, J, Sadana, A.K, Billups, W.E, Barron, A.R. Epoxidation and deoxygenation of single-walled carbon nanotubes for the preparation method of 0.8g graphene oxide and 0.2g epoxidized carbon nanotubes: Quantification of epoxydefects.J Am Chem Soc, 2006,128,11322-11323) was added in 100mL ethanol, stirred and ultrasonically dispersed evenly to form a graphene oxide-epoxidized carbon nanotube dispersion, which was set aside;

[0035] (3), add the graphene oxide-epoxidized carbon nanotube dispersion formed in step (2) into step (1), reflux at 90°C for 24h, wash repeatedly with ethanol and water, and centrifuge t...

Embodiment 2

[0039] A preparation method of anthraquinone molecule co-grafted carbon / conductive polymer composite material, which differs from Example 1 in that:

[0040] In step (1), 1g of 1,4-diaminoanthraquinone becomes 2g of 2,6-diaminoanthraquinone;

[0041] In step (2), the quality of graphene oxide becomes 0.01g, and the quality of epoxidized carbon nanotube becomes 0.04g;

[0042] In step (4), 0.465 g of anthraquinone molecule co-grafted carbon dispersed in 155 mL of water becomes 0.0134 g of anthraquinone molecule co-grafted carbon dispersed in 26.8 mL of water (concentration 0.5 g / L);

[0043] In step (5), 0.465g (5mmol) aniline becomes 0.268g (4mmol) pyrrole, 0.2575g sodium polystyrene sulfonate (1.25mmol) becomes 2.7878g (8mmol) sodium dodecylbenzenesulfonate, 0.81 g (5mmol) ferric chloride becomes 0.9128g (4mmol) ammonium persulfate; 24h at 0°C becomes 12h at 30°C;

[0044] In step (3), the reflux at 90°C for 24h was changed to reflux at 80°C for 36h.

Embodiment 3

[0046] A preparation method of anthraquinone molecule co-grafted carbon / conductive polymer composite material, which differs from Example 1 in that:

[0047] In step (1), 1g of 1,4-diaminoanthraquinone becomes 0.1g of 1,5-diaminoanthraquinone;

[0048] In step (2), the quality of graphene oxide becomes 0.1g, and the quality of epoxidized carbon nanotube becomes 0.1g;

[0049] In step (4), 0.465 g of anthraquinone molecule co-grafted carbon dispersed in 155 mL of water becomes 0.108 g of anthraquinone molecule co-grafted carbon dispersed in 108 mL of water (concentration 1 g / L);

[0050] In step (5), 0.465g (5mmol) aniline becomes 1.08g (10mmol) m-phenylenediamine, 0.2575g sodium polystyrene sulfonate (1.25mmol) becomes 0.83g (5mmol) terephthalic acid, 0.81g (5mmol) ferric chloride changed to 2.7032g (10mmol) potassium persulfate; 24h reaction at 0°C changed to 18h reaction at 15°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com