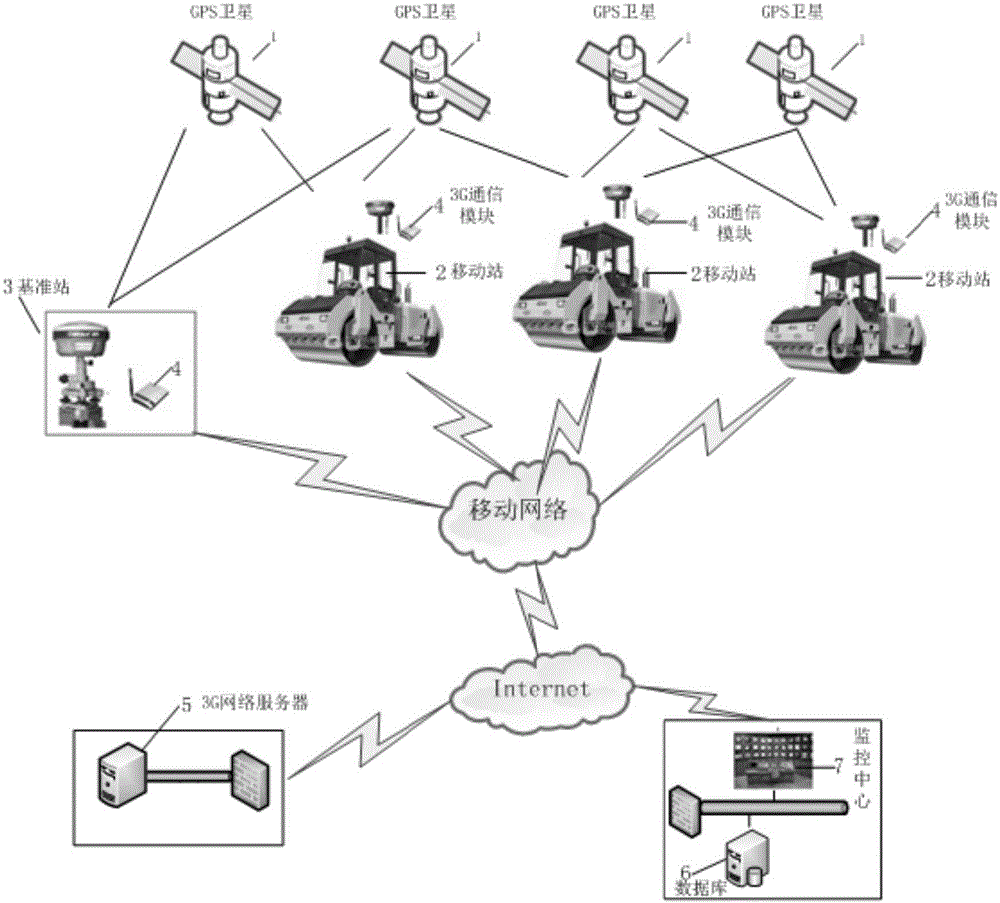

Real-time monitoring method for the dynamic process of roadbed rolling and constructing

A dynamic process, road construction technology, applied in the direction of roads, roads, road repair, etc., can solve the problems of lack of comprehensive consideration, narrow use area, single monitoring indicators, etc., to ensure construction quality, speed up construction progress, and broad application prospects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

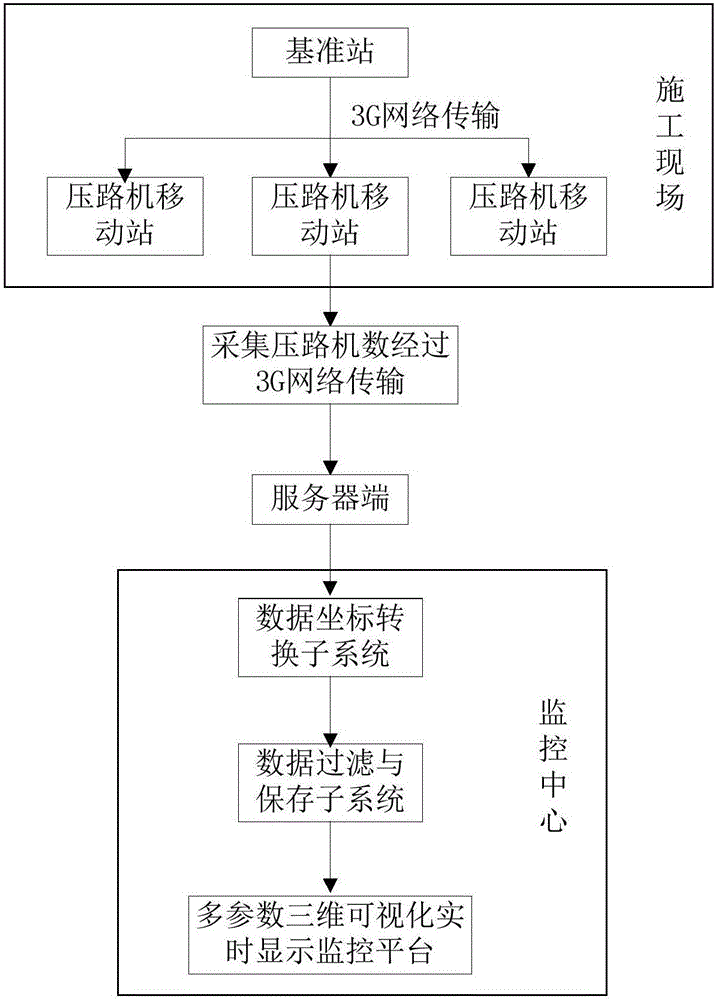

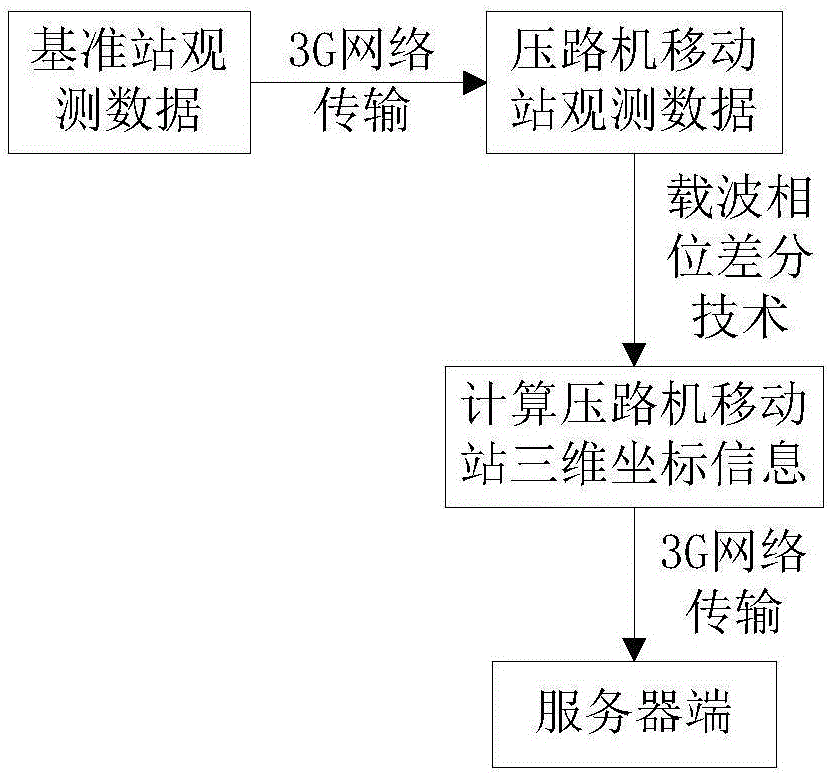

Method used

Image

Examples

Embodiment

[0055] The monitoring center realized the multi-parameter three-dimensional visualization display of the dynamic process of rolling from Dongxiang to Changfu Expressway, Figure 4 It is the situation of the three-dimensional visualization information display of the rolling pass by the monitoring center, Figure 5 It is the situation that the monitoring center displays the three-dimensional visualization information of the compaction height, Image 6 It is the situation where the monitoring center displays the three-dimensional visualization information of flatness. Image 6 The middle number ① represents the flatness of each color; Image 6 The middle number ② is the smoothness of the roadbed; Image 6 The middle number ③ shows the current time and rolling information; Image 6 The middle number ④ is the number of layers in the rolling process; Image 6 The middle number ⑤ is a section view of flatness; Image 6 The middle number ⑥ is the cross-sectional view of compaction height o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com