Emissivity calibration method for infrared temperature measurement system

A technology of infrared temperature measurement and calibration method, which is applied in the field of infrared temperature measurement, can solve the problems that the emissivity of objects is prone to errors, affect the temperature measurement accuracy, and increase the hardware configuration, so as to overcome the defects of emissivity correction, increase power consumption, simple method effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

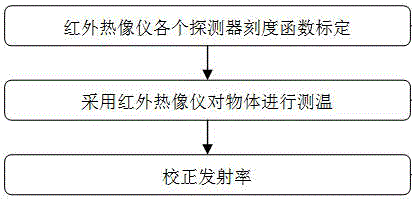

[0037] like figure 1 As shown, the emissivity calibration method for the infrared temperature measurement system includes the following steps:

[0038] S1: Use a temperature-controllable black body to calibrate the calibration functions of each detector of the infrared thermal imager at close range;

[0039] S2: Use an infrared thermal imager to measure the temperature of the object;

[0040] S3: Correct the emissivity.

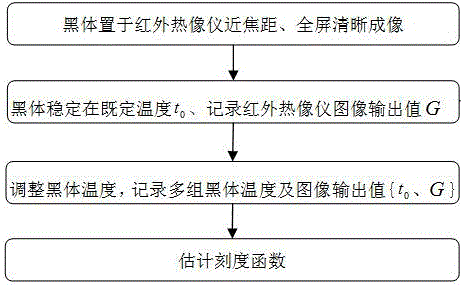

[0041] like figure 2 As shown, the calibration of the detector calibration function in the step S1 specifically includes the following steps:

[0042] S11: The black body is placed in the clear imaging place of the infrared thermal imager near the focal length, and the black body is filled with the image screen. The b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com