Nano-diamond/carbon fiber carbon composite material and preparing method thereof

A technology of nano-diamond and carbon fiber carbon, which is applied in the direction of fiber chemical characteristics, rayon manufacturing, textiles and paper making, etc., can solve the problems of high process requirements and operation cost, complicated operation, high cost of raw materials, etc., to increase thermal conductivity and improve manufacturing process Convenience and improved thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The specific steps of the preparation method of the nano-diamond / carbon fiber carbon composite material in this embodiment are as follows:

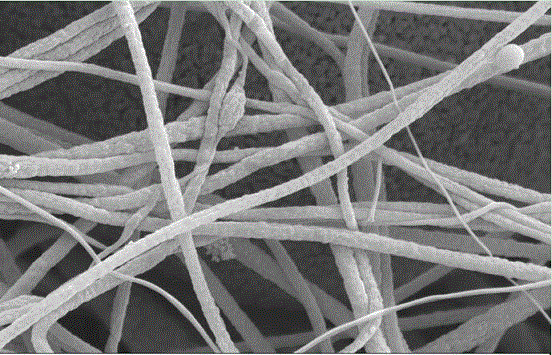

[0030] (1) Dissolving the polyacrylonitrile polymer in dimethylformamide to obtain a polyacrylonitrile dimethylformamide solution, the mass percent concentration of the polyacrylonitrile dimethylformamide solution being 4%;

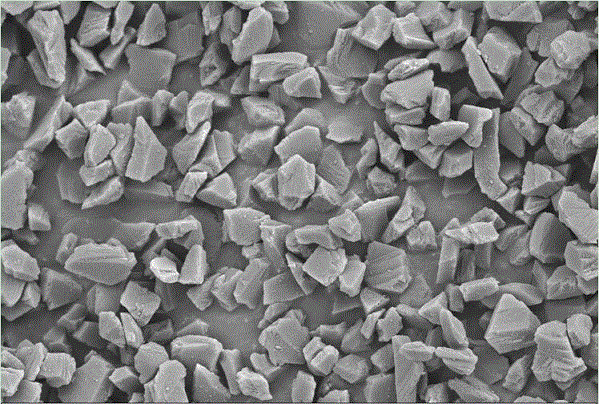

[0031] (2) Select single crystal diamond with a particle size of 5-10 μm, add the single crystal diamond into the ball mill, run the ball mill at a speed of 300rpm for 50 hours for crushing, and put the powder into 10% dilute hydrochloric acid solution after crushing , heated and reacted at 70°C for 1 hour, washed with water until the pH value was 7, dehydrated and dried to obtain nano-diamonds, and the particle size of nano-diamonds was 1nm;

[0032] The nano-diamond is subjected to the following surface treatment: the aluminum isopropoxide, tetraethyl silicate and hydrochloric acid catalyst are polymerized i...

Embodiment 2

[0036] The specific steps of the preparation method of the nano-diamond / carbon fiber carbon composite material in this embodiment are as follows:

[0037] (1) Dissolving the polyacrylonitrile polymer in dimethylformamide to obtain a polyacrylonitrile dimethylformamide solution, the concentration of the polyacrylonitrile dimethylformamide solution being 6% by mass;

[0038] (2) Select single crystal diamond with a particle size of 8 μm, add the single crystal diamond into the ball mill, and run the ball mill at a speed of 300 rpm for 100 hours for crushing. After crushing, put the powder into 15% dilute hydrochloric acid solution, Heat and react at 80°C for 2 hours, wash with water until the pH value is 8, dehydrate and dry to obtain nano-diamonds, the particle size of nano-diamonds is 10nm;

[0039] The nano-diamond is subjected to the following surface treatment: the aluminum isopropoxide, tetraethyl silicate and hydrochloric acid catalyst are polymerized in an aqueous medium...

Embodiment 3

[0043] The specific steps of the preparation method of the nano-diamond / carbon fiber carbon composite material in this embodiment are as follows:

[0044] (1) dissolving the polyacrylonitrile polymer in dimethylformamide to obtain a polyacrylonitrile dimethylformamide solution, the concentration of the polyacrylonitrile dimethylformamide solution being 10% by mass;

[0045] (2) Select single crystal diamond with a particle size of 8 μm, add the single crystal diamond into the ball mill, and run the ball mill at a speed of 300rpm for 150 hours for crushing. After crushing, put the powder into 18% dilute hydrochloric acid solution. Heating and reacting at 90°C for 3 hours, washing with water until the pH value is 8, dehydrating and drying to obtain nano-diamonds, the particle size of nano-diamonds is 600nm;

[0046] The nano-diamond is subjected to the following surface treatment: the aluminum isopropoxide, tetraethyl silicate and hydrochloric acid catalyst are polymerized in an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com