Directionally-arranged graphene/epoxy resin high-thermal-conductivity composite material and preparation method thereof

A technology of directional alignment and epoxy resin, which is applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems that are not beneficial to waste recycling and environmental protection, difficult to industrialize mass production, and graphene film is fragile. Achieve the effects of reducing material costs, protecting the environment, and reducing the number of interfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

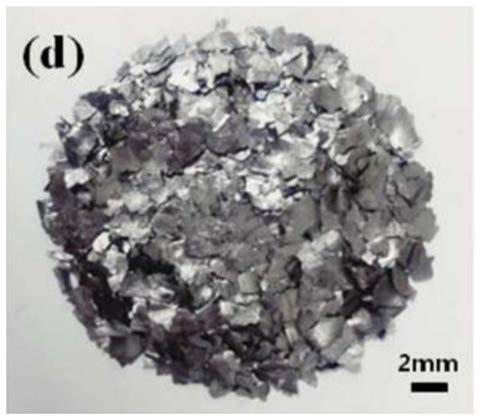

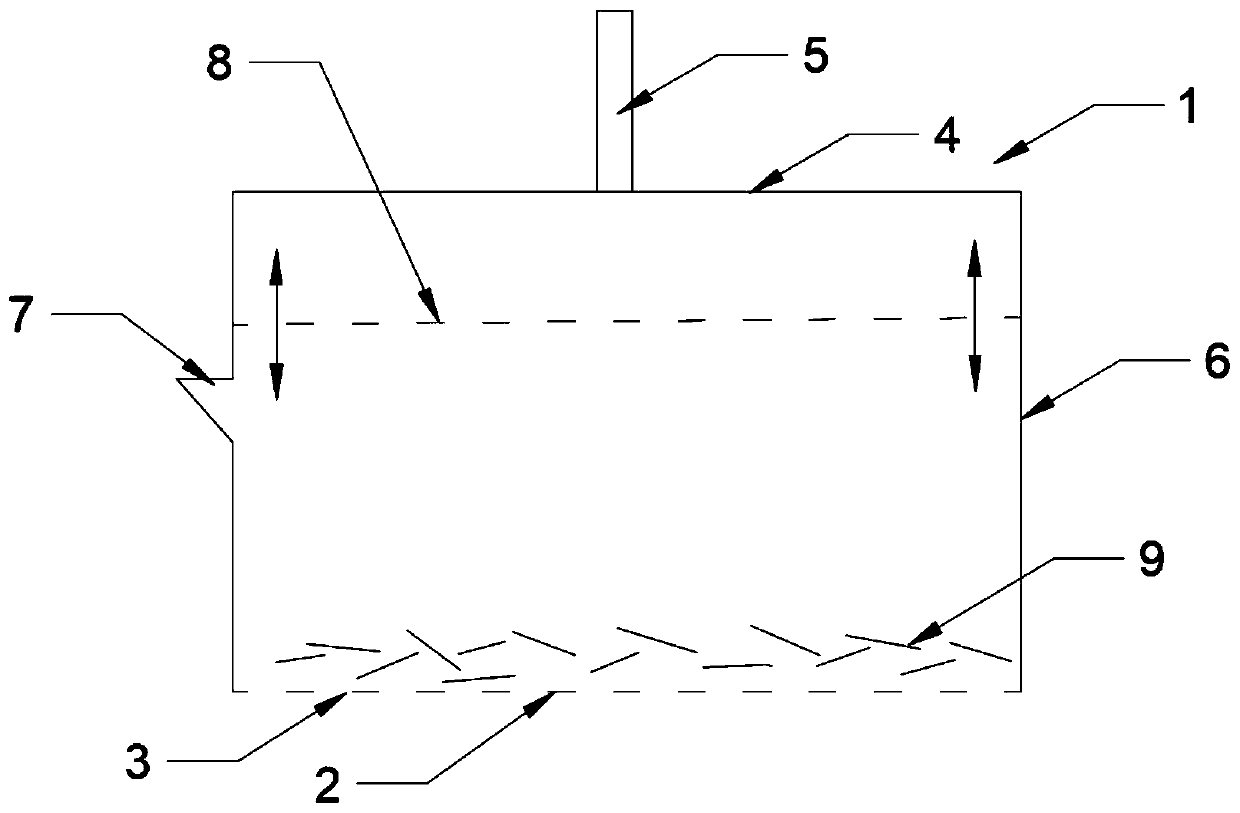

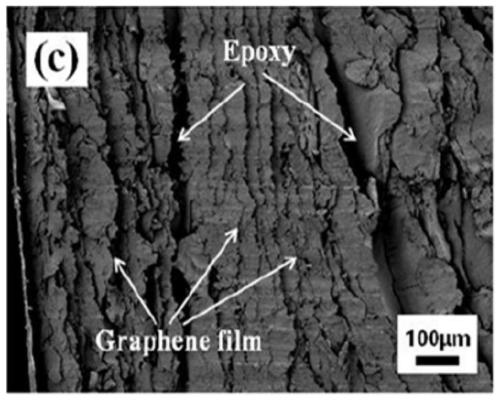

[0043] See attached Figure 1~3 , the oriented arrangement graphene / epoxy resin high thermal conductivity composite material provided in this embodiment, it is 5~20 μm by oriented arrangement thickness, the graphene soaking film fragments that lateral dimension is 0.5~3mm is used as heat conduction filler, and pouring And the epoxy resin covering the heat conducting material is solidified at high temperature together, so that the graphene heat soaking film fragments are finally oriented and arranged; calculated according to the mass percentage, it is made of the following ratio of graphene heat soaking film fragments and epoxy resin Composition: Graphene soaking film fragments: 32.63%, epoxy resin: 67.37%.

[0044] The graphene heat soaking film fragments are made by recycling and pulverizing the remaining corner waste after die cutting of the graphene heat soaking film commonly used in the electronics industry.

[0045] The preparation method of the aligned graphene / epoxy re...

Embodiment 2

[0053] see figure 2 , the aligned graphene / epoxy resin high thermal conductivity composite material and preparation method thereof provided by the present embodiment are basically the same as in Example 1, except that:

[0054] Calculated by mass percentage, it is made of graphene heat soaking film fragments and epoxy resin in the following proportions: graphene heat soaking film fragments: 28.5%, epoxy resin: 71.5%.

[0055] (1) Mechanically pulverize the waste graphene heat soaking film with a thickness of 5 μm for 3 minutes, sieve, and select the graphene heat soaking film fragments filtered out with a sieve diameter between 0.5 and 3 mm for future use.

[0056] (2) Divide the fragments of the graphene soaking film into 10 parts, 1 part of which is evenly added to a specific mold through the side feed port, and then gently cover the equalizer plate on the fragments of the graphene soaking film, and place The upper part of the mold, the surroundings and the feed port are s...

Embodiment 3

[0062] The oriented arrangement graphene / epoxy resin high thermal conductivity composite material and preparation method thereof provided in this embodiment are basically the same as one of Embodiments 1 and 2, except that:

[0063] Calculated by mass percentage, it is made of graphene heat soaking film fragments and epoxy resin in the following proportions: graphene heat soaking film fragments: 20%, epoxy resin: 80%.

[0064] The thermal conductivity of the epoxy resin / aligned graphene heat soaking film composite material along the arrangement direction of the graphene heat soaking film is 10W / (m·K).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com