A method for controlling Ti content in converter tapping of chromium-containing alloy steel

An alloy steel and converter technology, which is applied in the manufacture of converters and other directions to achieve the effects of improving quality, reducing steelmaking process costs, and reducing power transmission time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Taking the smelting of SUJ2 type chromium-containing alloy steel as an example, proceed according to the following process steps. The chemical composition of the chromium-containing alloy steel is: C: 0.96, Si: 0.021, Mn: 0.35, P: 0.011, S: 0.001, Al: 0.027, Ca: 0.0004, Cr: 1.46, Ti: 0.0019, Yu The amount is iron.

[0023] 1) Pretreatment of molten iron, the condition of molten iron after pretreatment is as follows:

[0024] C,%

Si,%

Mn,%

P,%

S,%

Ti,%

T,℃

weight, t

4.07

0.59

0.29

0.119

0.001

0.060

1326

100

[0025] Use pretreated molten iron to reduce desulfurization pressure in converter smelting process.

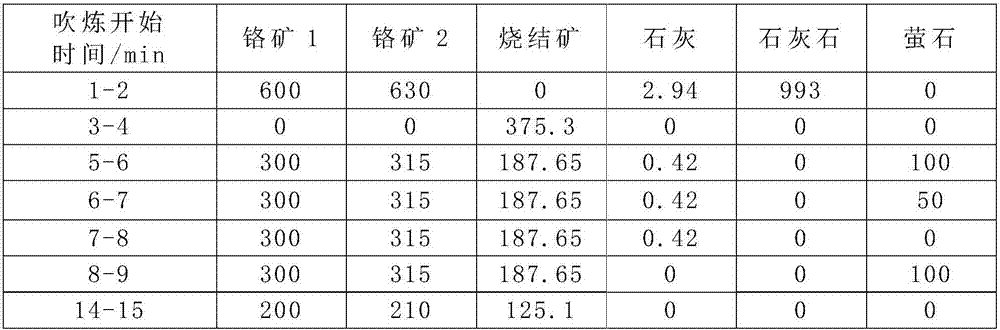

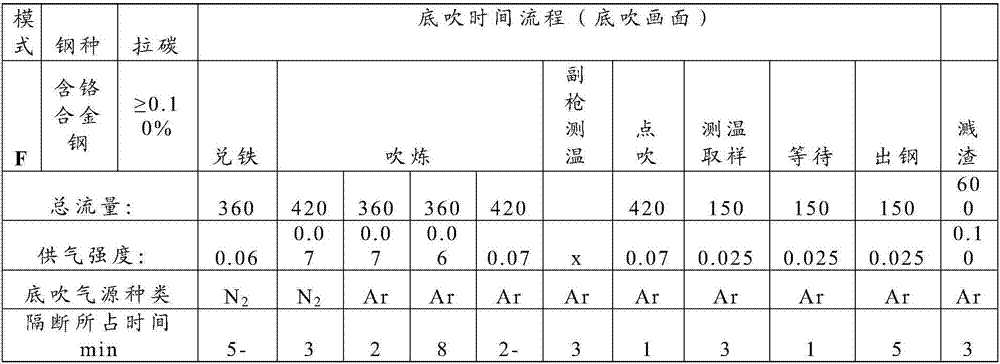

[0026] 2) The converter is smelted by the single slag leaving slag method, and the recovery rate of Cr element is improved by using the saturated Cr in the previous slag, and the recovery rate of Cr can reach more than 45%. In blowing for 1 minute and 30 seconds, 3t of lime, 1t of limestone and 1.2t...

Embodiment 2

[0034] Chromium-containing alloy steel SUJ2, the chemical composition of the chromium-containing alloy steel is: C: 0.98, Si: 0.023, Mn: 0.34, P: 0.009, S: 0.001, Al: 0.028, Ca: 0.0005, Cr: 1.45, Ti: 0.0017, the balance is iron.

[0035] 1) After the pretreatment of molten iron, the condition of molten iron.

[0036] C,%

Si,%

Mn,%

P,%

S,%

Ti,%

T,℃

weight, t

4.58

0.56

0.27

0.118

0.001

0.064

1309

100

[0037] Use pretreated molten iron to reduce desulfurization pressure in converter smelting process.

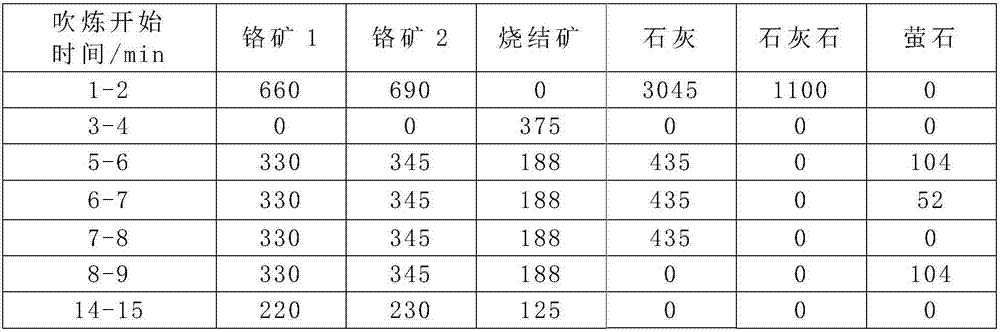

[0038] 2) The converter is smelted by the single slag leaving slag method, blowing for 1 minute and 30 seconds and concentratedly adding 3.1t of lime and 1.35t of chromium ore for 1 minute and 30 seconds of blowing. Concentrated addition of chromium ore in the early stage can increase the yield of Cr element. Add chrome ore, fluorspar, lime, etc. in batches after blowing for 3 minutes. A total of 4.35t of lime, 4.5...

Embodiment 3

[0047] Chromium-containing alloy steel SUJ2, the chemical composition of the chromium-containing alloy steel is: C: 0.99, Si: 0.021, Mn: 0.36, P: 0.009, S: 0.001, Al: 0.025, Ca: 0.0005, Cr: 1.46, Ti: 0.0017, the balance is iron.

[0048] 1) After the pretreatment of molten iron, the condition of molten iron.

[0049] C,%

Si,%

Mn,%

P,%

S,%

Ti,%

T,℃

weight, t

4.70

0.53

0.30

0128

0.001

0.054

1388

100

[0050] Use pretreated molten iron to reduce desulfurization pressure in converter smelting process.

[0051] 2) The converter is smelted by the single slag leaving slag method, and the slagging material 3t of lime and 1.23t of chrome ore are concentratedly added in 1 minute and 30 seconds of blowing, (the concentration of chromium ore added in the early stage can increase the yield of Cr element) and blowing for 3 minutes Then add chrome ore, fluorspar, lime, etc. in batches, adding 4.01t of lime, 4.1t of chrome ore...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com