Preparation method for MXDI

An organic solvent and solution technology, applied in the field of preparation of organic compounds, can solve the problems of easy generation of chlorinated substances and high free chlorine, and achieve the effect of shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

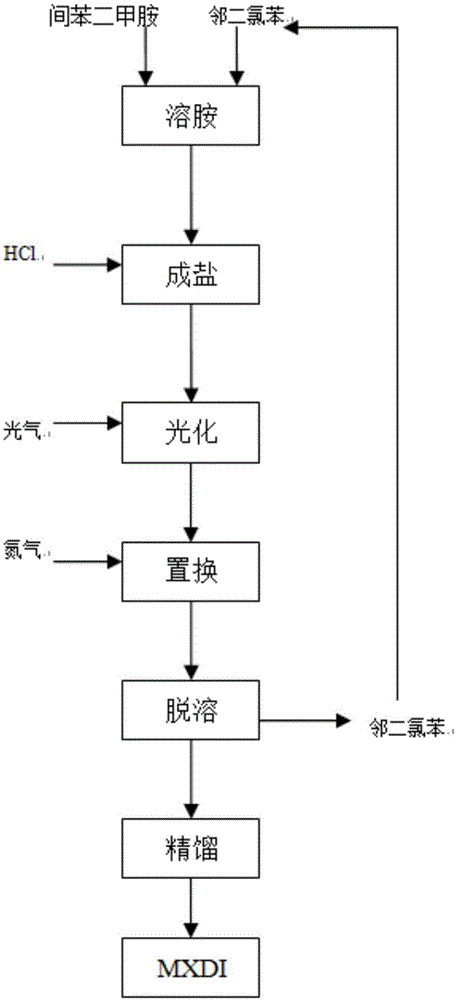

Method used

Image

Examples

Embodiment 1

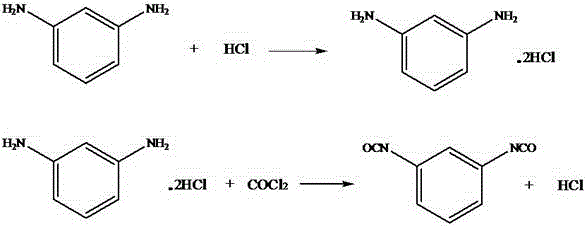

[0028] Put 30g of m-xylylenediamine and 390g of o-dichlorobenzene into a 500ml four-neck flask equipped with stirring, thermometer, gas guide tube and condenser tube, raise the temperature to 125~130°C, and feed dry HCl gas while stirring, Adjust system pH=2~3. Raise the temperature to 135~140°C, pass phosgene under vigorous stirring, pass phosgene at 135~140°C for 2 hours, pass phosgene at 145~150°C for 2 hours, and finally pass phosgene at 155~160°C until the solution is transparent. Then cool down to 40~45°C, and pass through dry nitrogen for 2h. Then the solvent was removed under reduced pressure, and the pure product of MXDI was obtained by rectification under reduced pressure.

[0029] 33.6g of pure MXDI was obtained in the experiment, the content was 99.7% by gas spectrometry analysis, the single impurity was less than 0.2%, and the yield was 80.2%.

Embodiment 2

[0031] The process steps are the same as in Example 1, except that the feeding amount of m-xylylenediamine is 50 g, and that of o-dichlorobenzene is 650 g.

[0032] 57.3g of pure MXDI was obtained in the experiment, the content was 99.6% by gas spectrometry analysis, the single impurity was less than 0.2%, and the yield was 82%.

Embodiment 3

[0034] The process steps are the same as in Example 1, except that the feeding amount of n-xylylenediamine is 100 g, xylene is 1300 g, and benzyltriethylammonium chloride is 1 g.

[0035] 119.6g of pure MXDI was obtained in the experiment, the content was 99.8% by gas spectrometry analysis, and the yield was 85.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com