Wastewater treatment ICBB(inorganic coagulant and biological bacteria) process and device in ginkgo biloba extract extracting process

An extraction process and wastewater treatment technology, applied in the field of wastewater treatment and ginkgo biloba extract, can solve the problems of low treatment efficiency, the wastewater is difficult to meet the effluent requirements, and the effluent quality is unstable, and achieves high treatment efficiency, improved biodegradability, The effect of improving biodegradability and aerobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

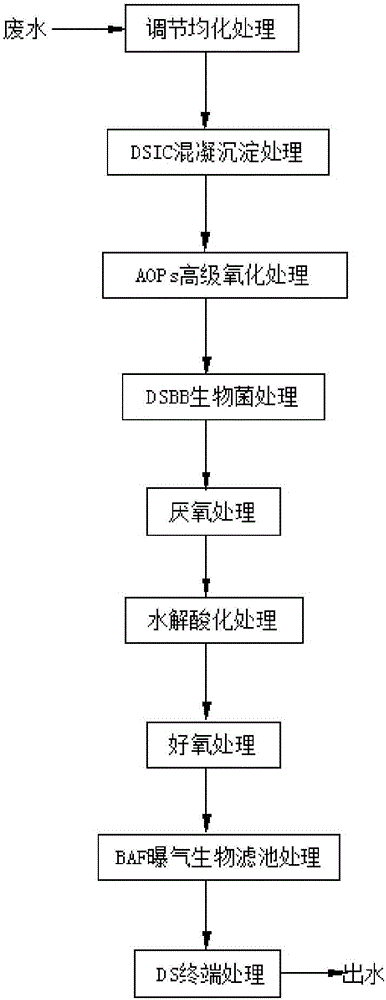

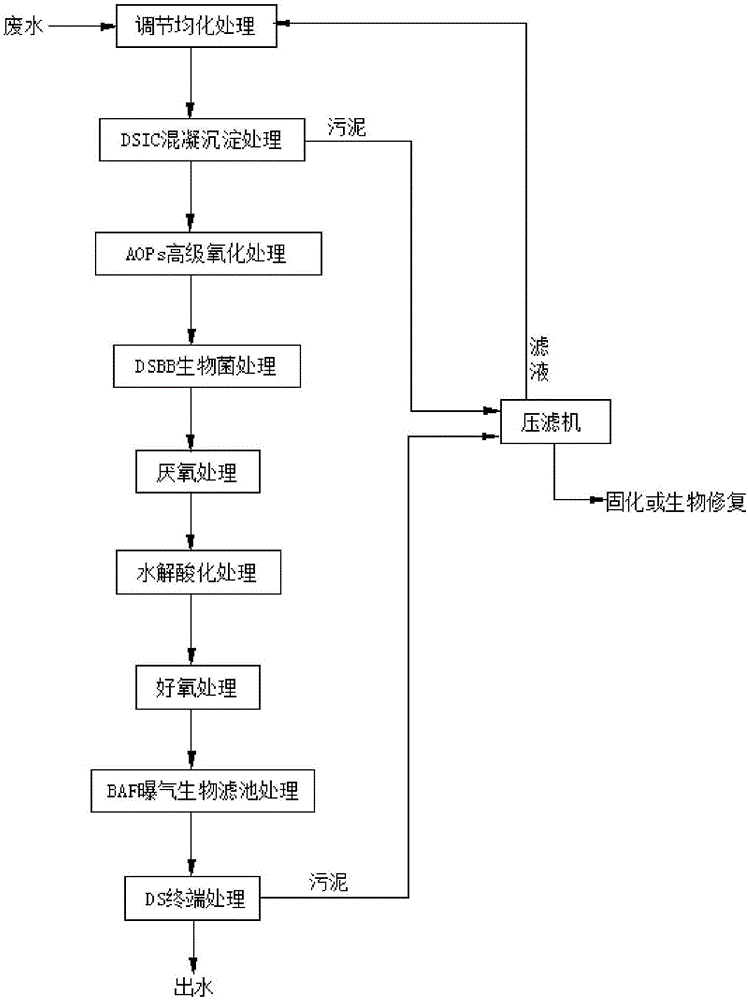

[0097] Such as figure 1 and figure 2 As shown, the waste water treatment ICBB process in the extraction process of the ginkgo biloba extract of the present embodiment comprises the following steps:

[0098] (1) Regulating homogenization treatment: introduce the waste water to be treated into the regulating homogenization tank for homogenization regulation of water quality and quantity, and adjust the pH value of the waste water to 6 by adding alkaline aqueous solution or acidic aqueous solution;

[0099] (2) DSIC coagulation and sedimentation treatment: introduce the wastewater treated in step (1) into the coagulation sedimentation tank, and add coagulant and alkalization agent in turn for coagulation and sedimentation treatment; the coagulation pH is 8, and the coagulation and stirring time was 10 minutes, and the precipitation time was 30 minutes.

[0100] Among them, the coagulant is DSIC inorganic coagulant, and the DSIC inorganic coagulant is a mixture of alumina and c...

Embodiment 2

[0117] In the present embodiment, except step (5) anaerobic treatment is different from embodiment 1, all the others are the same as embodiment 1.

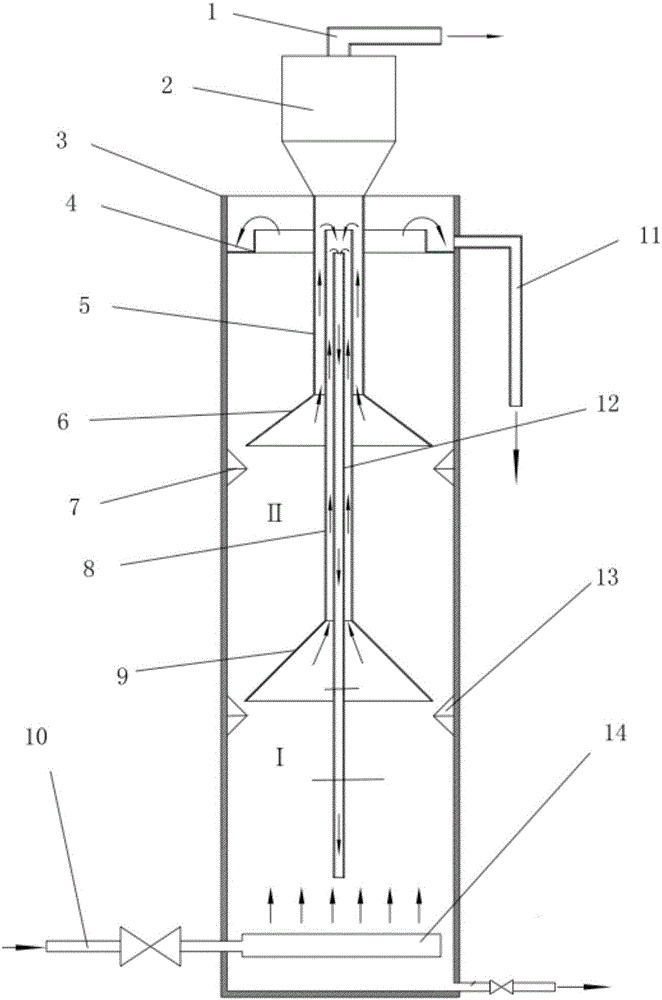

[0118] The anaerobic treatment in this embodiment adopts such as image 3 The anaerobic reactor shown performs anaerobic treatment.

[0119] Specifically, the wastewater treated by biological bacteria enters the reactor shell 3 through the water inlet pipe 10, and then the water distributor 14 distributes the incoming water in the mixing zone in the reactor shell 3, and the water from the return pipe 12 The mud-water mixture in the internal circulation is mixed to dilute and homogenize the incoming water. Under the joint promotion of influent water and circulating water, the mixed wastewater and granular sludge enter the first anaerobic zone 13 (also known as the granular sludge expanded bed zone) for biochemical degradation, because this treatment zone has a high volume load In addition, due to the large height-to-diameter rati...

Embodiment 3

[0123] In this embodiment, the difference from embodiment 1 is:

[0124] (1) During the homogenization treatment, the pH value of the waste water is 7;

[0125] (2) In DSIC coagulation and sedimentation treatment, the coagulation pH is 9, the coagulation stirring time is 15 minutes, and the precipitation time is 60 minutes; the dosage of coagulant is 1g / L, and the dosage of alkalizing agent is 5g / L;

[0126] Wherein, the coagulant is a DSIC inorganic coagulant, and the DSIC inorganic coagulant is a mixture of calcium oxide, sodium carbonate and potassium carbonate; the alkalizing agent is a mixture of calcium hydroxide and sodium hydroxide;

[0127] (4) In the treatment of DSBB biological bacteria, the dosage of DSBB biological bacteria accounts for 0.01% of the weight of wastewater;

[0128] Among them, DSBB biological bacteria include ammonifying bacteria, nitrifying bacteria, achromobacter, Flavobacterium and denitrifying bacteria;

[0129] (9) In the DS terminal treatm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com