Technology for using organic contaminated high salinity wastewater to produce industrial refined salt

A technology for high-salt wastewater and organic pollution, applied in the direction of water pollutants, water/sewage treatment, neutralized water/sewage treatment, etc., can solve problems such as no treatment process, not in line with environmental protection concepts, production hazards, etc., to reduce equipment Investment cost, solution to waste gas treatment problems, and significant environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

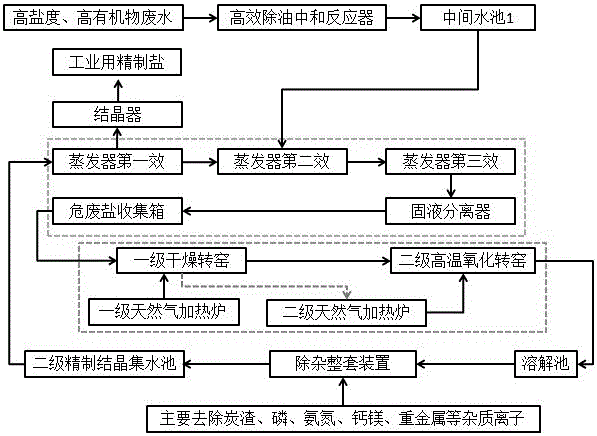

Method used

Image

Examples

Embodiment 1

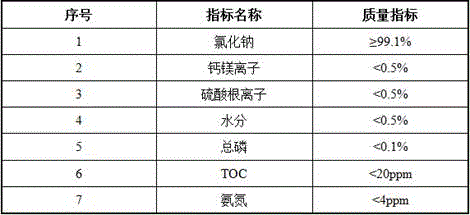

[0035] Embodiment 1: The wastewater in this implementation example is taken from the high-salinity wastewater of a certain pesticide factory, and the main product is chlorpyrifos, and its initial data are as shown in Table 2:

[0036] Table 2 Raw water initial data

[0037]

[0038] It can be seen from the data in Table 2 that the salt content in the wastewater is very high, above 10%; the concentration of organic matter is very high, and the organic matter belongs to the toxic and harmful substances of pesticides. Other pollution indicators such as ammonia nitrogen and total phosphorus are also high. In the production process of wastewater generation, the use of heavy metals is not involved, so the content of heavy metals is not very high, and the index of heavy metals is not the research focus of this experiment.

[0039] Waste water in table 2 is produced according to technique of the present invention, and its concrete experimental effect is as shown in table 3:

[00...

Embodiment 2

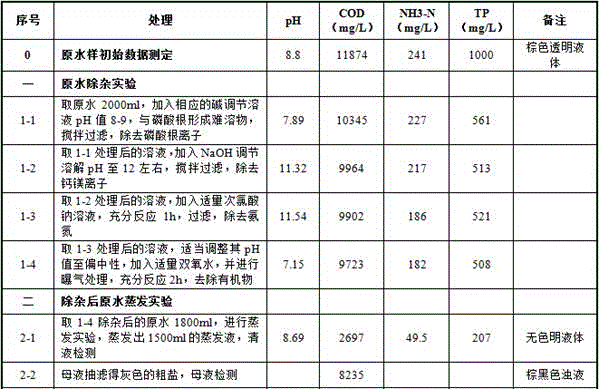

[0044] Example 2: The wastewater in this implementation example is taken from a pesticide factory with high salinity wastewater, the main product is chlorpyrifos, and its initial data are shown in Table 2. The raw water in Table 2 was tested according to the experimental steps in Table 4, and the specific effects are shown in Table 4:

[0045] Table 4 Details of experimental steps and experimental results

[0046]

[0047]

[0048] It can be seen from the data in Table 4 that the sequence in the process is impurity removal, evaporation and crystallization. In the impurity removal process, the phosphorus, calcium magnesium, ammonia nitrogen, organic matter and other factors in the raw water are mainly removed. After the impurity removal, the removal effect on impurity ions is not ideal, especially for the removal of organic matter. . Evaporation and crystallization is carried out on the waste water after impurity removal, and a part of impurity ions are taken away in th...

Embodiment 3

[0051] Embodiment 3: The operation method of the thermal desorption step of hazardous waste salt in step 3 of the present invention is as follows (using a secondary rotary kiln):

[0052] 1) Send the hazardous waste salt into the first-level rotary kiln, and pass the hot air heated by domestic gas into the rotary kiln. The temperature of the hot air is in the range of 100-150°C, and the hazardous waste salt is dried in and out to increase the salt fluidity;

[0053] 2) Enter the hot air and volatile organic compounds at the outlet of the first-stage rotary kiln into the natural gas heating furnace, on the one hand, increase the temperature of the hot air to within the range of 300-600°C; The organic waste gas produced by the kiln is incinerated and oxidized without causing air pollution;

[0054] 3) Pass the hot air heated to 300-600°C into the second-stage rotary kiln, and oxidize the salt initially dried in the first-stage rotary kiln at high temperature again, fully oxidiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com