Double-sided floor and manufacturing method thereof

A double-sided floor and floor technology, applied in floor covering, chemical instruments and methods, floors, etc., can solve the problems of limited floor application scenarios, insufficient hardness, and floor pollution, so as to improve product quality and product yield rate, and improve Production yield and product quality, the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

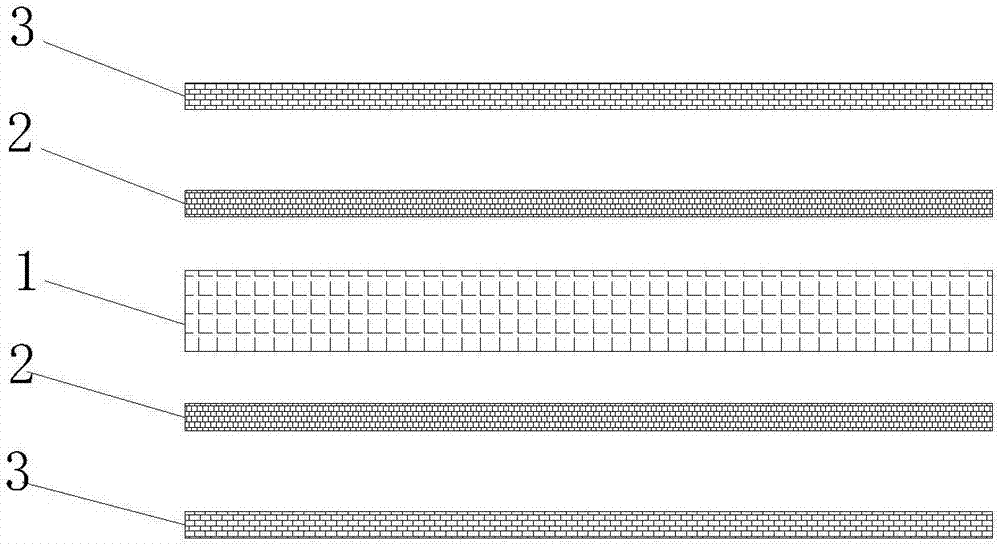

[0038] A double-sided floor, including a middle material, the two symmetrical sides of the middle material are respectively connected with color films, and the opposite outer sides of the two color films are respectively connected with frosted sheets.

[0039] Preferably, a sound-insulating layer film is provided between the middle material and the color film, which can effectively insulate, absorb, and reduce noise.

[0040] Preferably, the middle material is made according to the following material proportions by weight: 90-110 parts of PVC resin, 380-420 parts of stone powder, 25-35 parts of DOTP, 1-2 parts of stabilizer, and 0.3-0.6 parts of carbon black .

[0041] Preferably, as a further solution of the present invention, the middle material is made of the following materials in proportion by weight: 100 parts of PVC resin, 400 parts of stone powder, 30 parts of DOTP, 1.5 parts of stabilizer, and 0.5 parts of carbon black.

[0042] Preferably, the following materials ar...

specific Embodiment 2

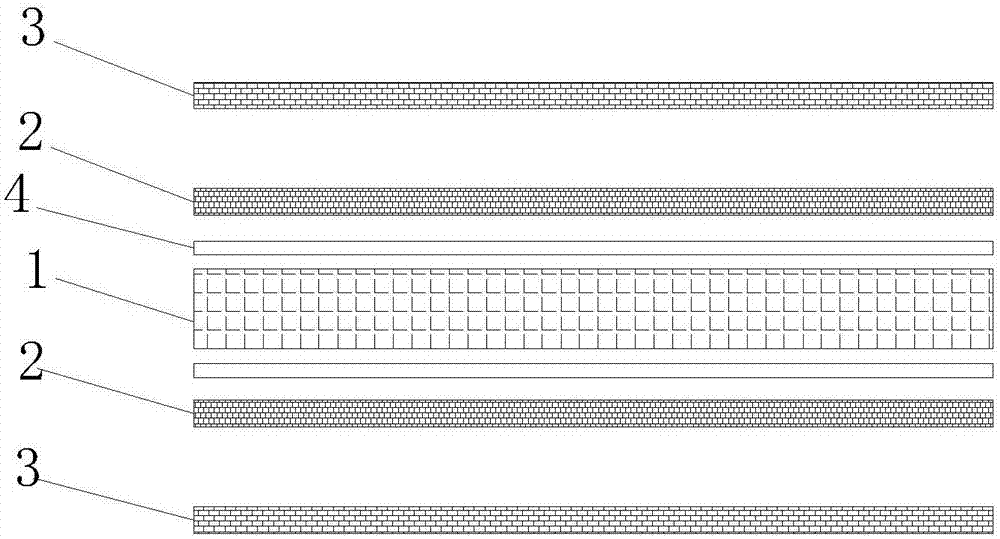

[0064] A double-sided floor, including a middle material, the two symmetrical sides of the middle material are respectively connected with color films, and the opposite outer sides of the two color films are respectively connected with frosted sheets.

[0065] Preferably, a sound-insulating layer film is provided between the middle material and the color film, which can effectively insulate, absorb, and reduce noise.

[0066] Preferably, the middle material is made according to the following material proportions by weight: 90-110 parts of PVC resin, 380-420 parts of stone powder, 25-35 parts of DOTP, 1-2 parts of stabilizer, and 0.3-0.6 parts of carbon black .

[0067] Preferably, as a further solution of the present invention, the middle material is made of the following materials in proportion by weight: 100 parts of PVC resin, 400 parts of stone powder, 30 parts of DOTP, 1.5 parts of stabilizer, and 0.5 parts of carbon black.

[0068] Preferably, the following materials ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com