Preparation method for carbon fiber composite reinforced board used for vehicle, and composite reinforced board

A reinforced plate and carbon fiber technology, applied in chemical instruments and methods, vehicle parts, transportation and packaging, etc., can solve the problems of difficult to meet the requirements of actual use, low modulus of glass fiber, etc., to increase the impact resistance and increase the combination Strength, increase the effect of thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

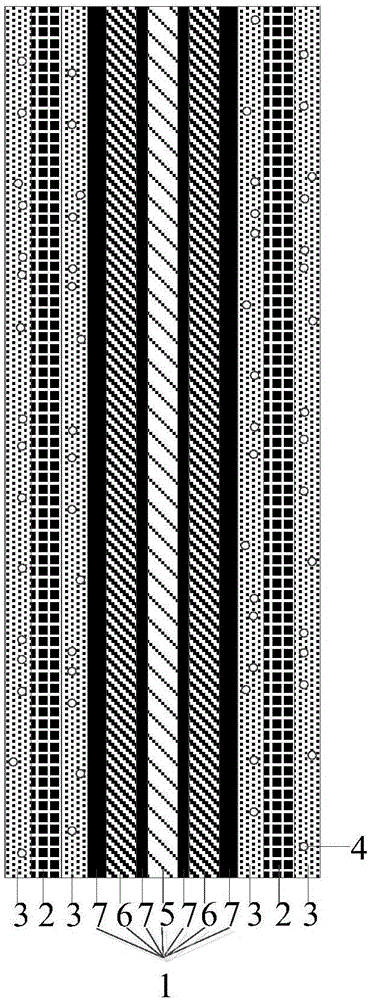

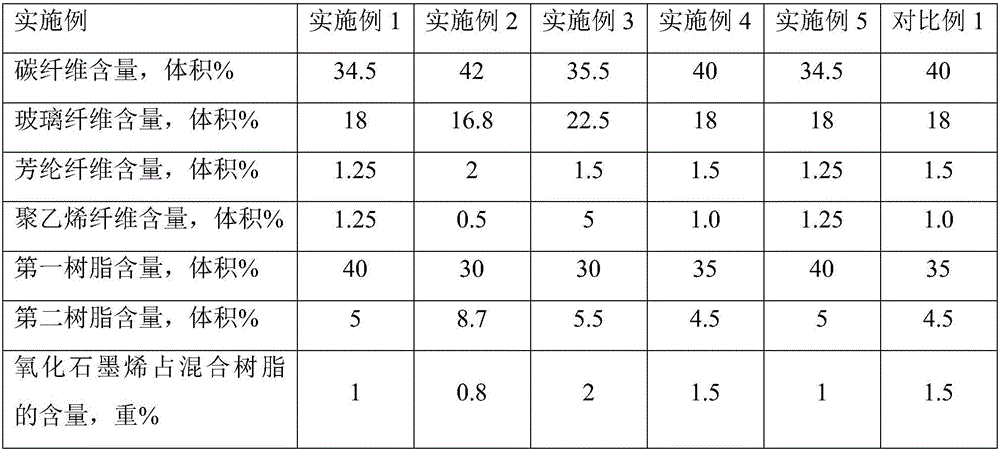

[0016] The disclosure provides a method for preparing a carbon fiber composite reinforced plate for vehicles. The preparation method includes: laying a carbon fiber braided layer and a glass fiber braided layer in superposition to obtain an inner fiber board; mixing graphene oxide and a first resin The resin is covered on the surface of the carbon fiber braided layer and the glass fiber braided layer, and the first compression molding is performed to obtain an inner layer composite board; the mixed braided layer made of aramid fiber and polyethylene fiber is covered on the said On the outer side of the inner layer composite board, the second resin and foaming agent are covered on the surface of the mixed braided layer and the inner layer composite board, and the second compression molding is performed to obtain a composite reinforced board.

[0017] According to the present disclosure, the second resin is molded together with the foaming agent, and the second resin of the obtai...

Embodiment 1

[0043] Graphene oxide (Changzhou Sixth Element Materials Technology Co., Ltd., 3-10 layers of graphene oxide) and epoxy resin particles (Huntsman) were evenly mixed and then heat-treated at 100° C. for 40 minutes to obtain a mixed resin.

[0044] Carbon fiber (Toray T700 carbon fiber in Japan) and glass fiber (Zhejiang Jushi Group Co., Ltd.) are woven into a carbon fiber braided layer and a carbon fiber braided layer of 1000 mm × 1000 mm × 0.3 mm, respectively, and then cut into 200 mm x 200 mm x 0.3 mm carbon fiber braid and carbon fiber braid.

[0045] Aramid fibers (Yantai Taihe New Materials Co., Ltd.) and polyethylene fibers (Beijing Tongyizhong Special Fiber Technology Development Co., Ltd.) were woven into a mixed weaving layer of 1000 mm × 1000 mm × 0.3 mm, and then Cut the mixed braid to 200mm x 200mm x 0.3mm.

[0046] The cut glass fiber braided layer and two carbon fiber braided layers are superimposed and laid, and the glass fiber braided layer is placed between t...

Embodiment 2

[0050] The preparation steps of Example 2 are basically the same as those of Example 1, except that graphene oxide and epoxy resin particles are not heat-treated, and are directly added to the mold for compression molding. The specific composition of the obtained composite reinforced plate is shown in Table 1 and the specific The properties are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com