Method and apparatus for producing foamed product based on 3D printing

A foamed product, 3D printing technology, applied in manufacturing auxiliary devices, 3D object support structures, manufacturing tools, etc., can solve the problems of high cost and complicated preparation process, and achieve simplified production, high molding accuracy, and simplified production process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

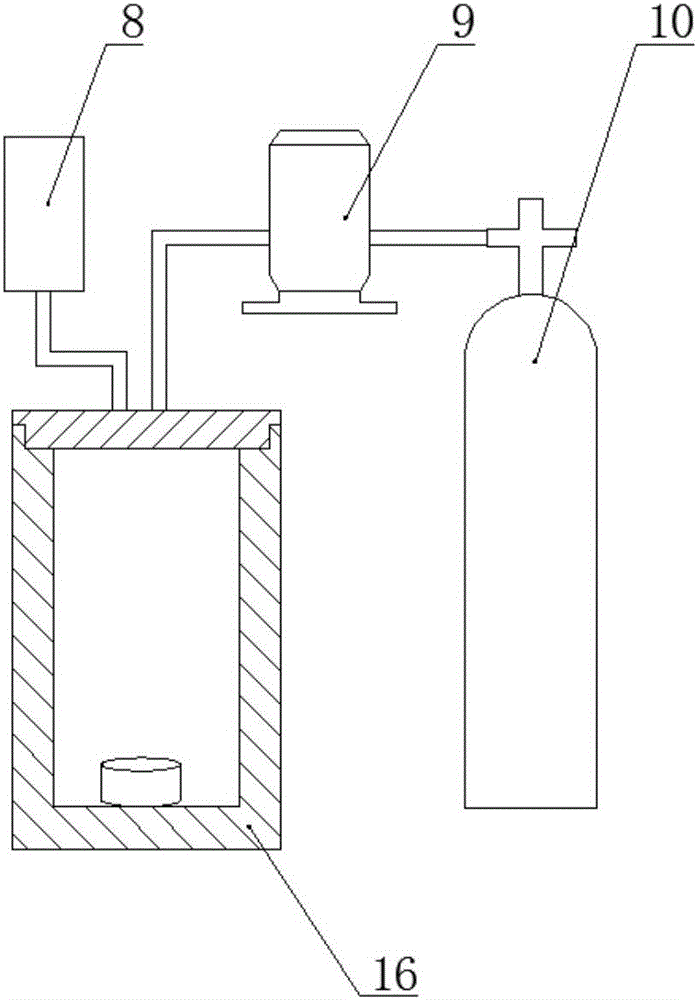

[0021] The present invention proposes a method and device for producing processed products combined with 3D printing, and the step-by-step schematic diagram is as follows figure 1 shown. The device is composed of a molding unit, a supercritical permeation unit and a foaming unit. The molding unit is mainly a 3D printer, including a three-dimensional ball screw slide 1, a molding platform 2, a 3D printer box 3, a plasticizing screw 4, a heating ring 5, a nozzle 6 and a closed box 17, such as figure 1 shown. The supercritical permeation unit is mainly composed of a preheater 8, a booster pump 9, a CO2 storage tank 10 and a permeation kettle 16, such as figure 2 shown. Foaming unit is mainly made up of steam generator 15, foaming box 11 and cover plate 12, as image 3 shown.

[0022] The invention relates to a method for producing processed goods combined with 3D printing, the working process of which is as follows: the first step, the three-dimensional forming process. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com