Manufacturing method for supporting seat of hydraulic cylinder of grate cooler

A manufacturing method and technology of hydraulic cylinders, which are applied in the direction of manufacturing tools, supports, metal processing mechanical parts, etc., can solve the problems of difficult positioning of the center of the hole, poor confirmation of the relationship between holes and holes, and unsuitable for batch parts, etc., to meet the production line. Assembly requirements, saving clamping correction time, optimizing the effect of the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with drawings and embodiments.

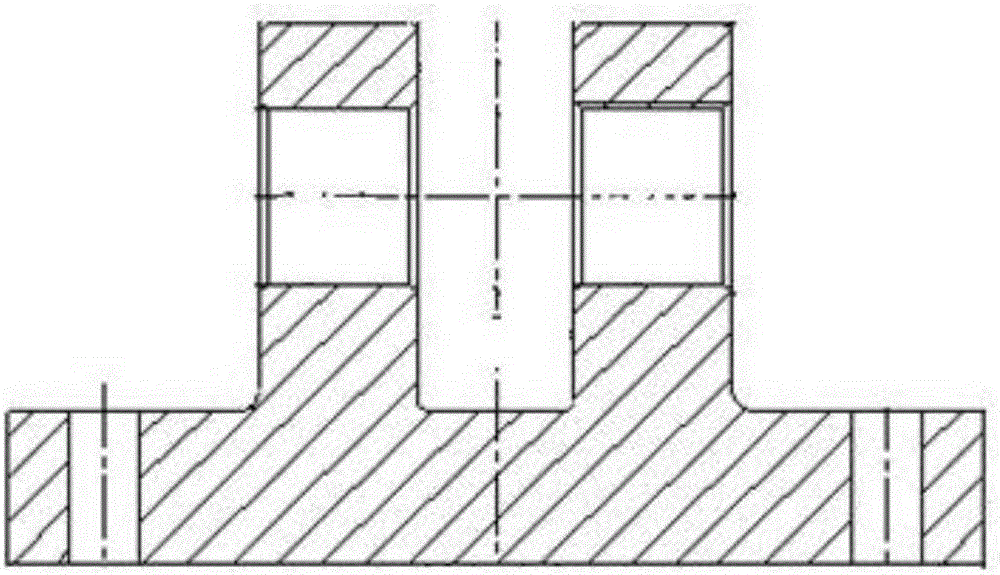

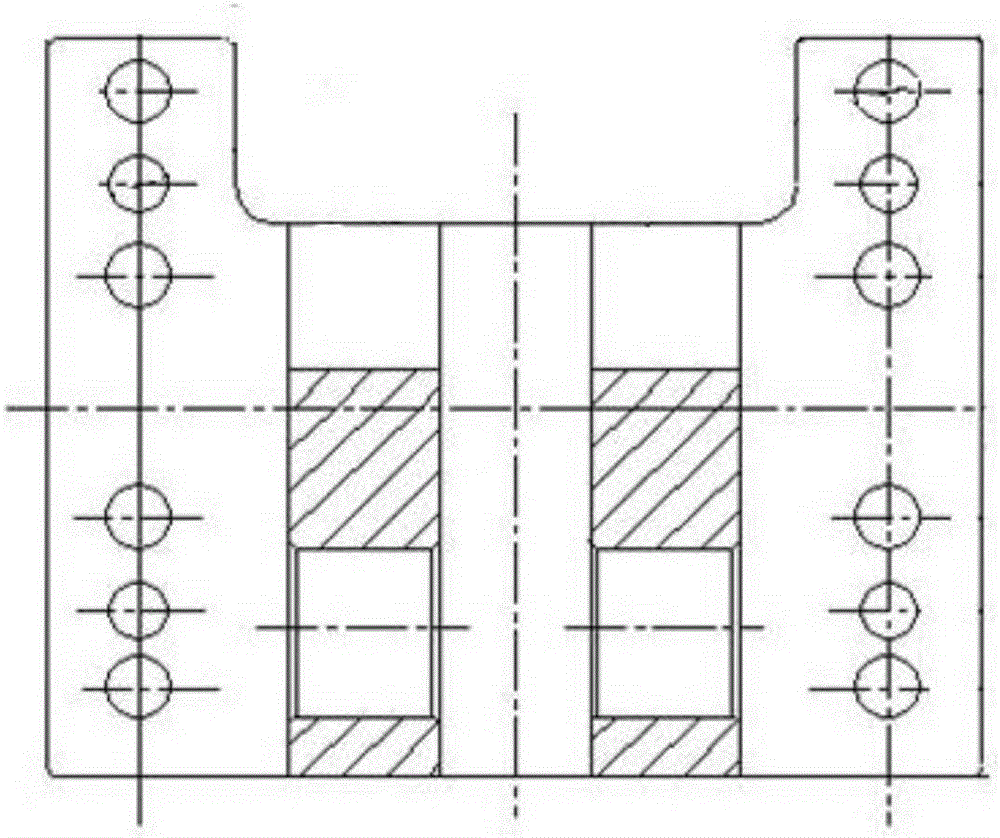

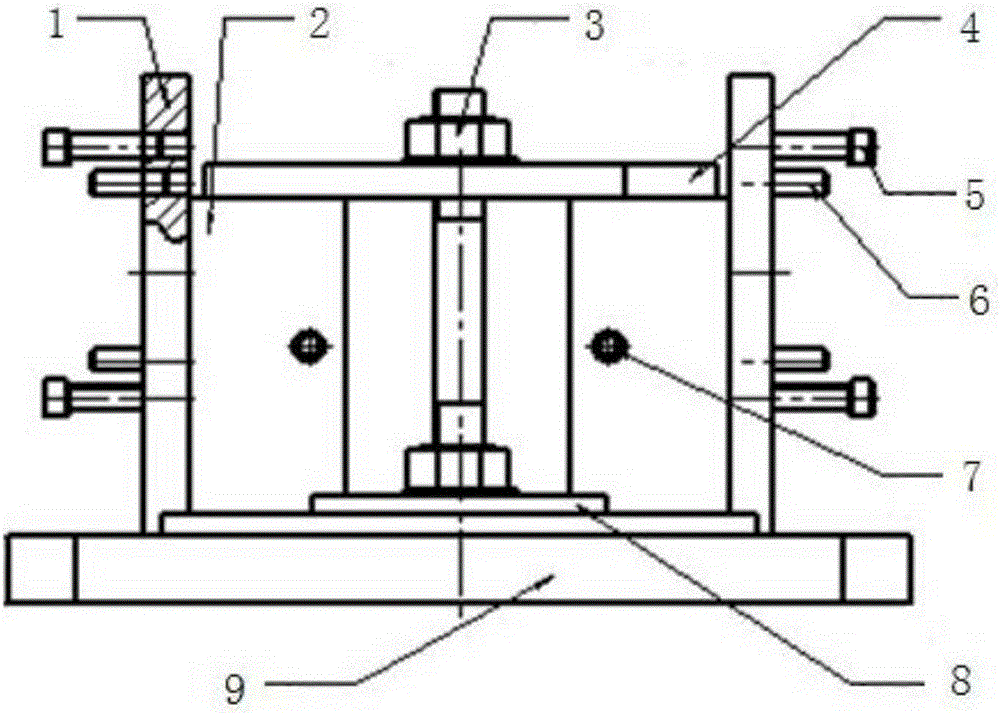

[0029] A method for manufacturing a hydraulic cylinder support of a grate cooler, using two sets of tooling fixtures that can process hydraulic cylinder supports in batches for processing. The two sets of tooling fixtures include tooling fixture I and tooling fixture II, and the tooling fixture I is used for Process the bottom plane, positioning keyway, bolt hole and positioning pin hole of the hydraulic cylinder support; the fixture II is used to process the inner notch of the double ear of the hydraulic cylinder support; the specific processing method is as follows:

[0030] Step 1. On the horizontal milling, first rough mill the riser of the bottom surface of the hydraulic cylinder support, leave a machining allowance of 1.5-2.5mm, and then use the side of the line milling as a positioning reference, and transfer to the HMC630e small CNC machining center after complet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com